Abstract

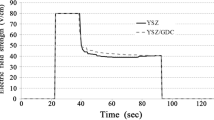

The thickness of an ultrathin blocking layer for anodic aluminum oxide (AAO)-supported thin-film solid oxide fuel cells is determined. The atomic layer-deposited (ALD) ultrathin yttria-stabilized zirconia (YSZ) blocking layer for gadolinia-doped ceria (GDC) electrolyte cell is deposited on 300 nm-thick Pt anode-coated AAO substrates. The surface of AAO substrates is examined to be non-uniform in terms of pore size and bump inclination by field emission scanning electron microscopic analysis. While the average pore size is 130 nm, the pore size ranges from 36 to 207 nm. While the average slope angle is 42°, the slope angle ranges from 9° to 79°. A growth modelling result considering the pore sizes and the slope angles presents that highly reliable ALD-deposited YSZ blocking layers need to be thicker than 93 nm. This prediction well corresponds to the evolution of open circuit voltages for 400 nm-thick GDC electrolyte cells with 60 nm-thick and 120 nm-thick ALD-deposited YSZ blocking layers.

Similar content being viewed by others

References

Lee, Y. H., Chang, I., Cho, G. Y., Park, J., Yu, W., Tanveer, W. H., et al. (2018). Thin film solid oxide fuel cells operating below 600°C: A review. International Journal of Precision Engineering and Manufacturing- Green Technology,5(3), 441–453.

Choi, H., Cho, G. Y., & Cha, S. W. (2014). Fabrication and characterization of anode supported YSZ/GDC bilayer electrolyte SOFC using dry press process. International Journal of Precision Engineering and Manufacturing-Green Technology,1(2), 95–99.

Lee, Y. H., Lee, S., Zeng, J., Cha, S. W., & Chang, I. (2019). Au-coated lanthanum strontium cobalt ferrite cathode for lowering sheet resistance of a solid oxide fuel cell. International Journal of Precision Engineering and Manufacturing,20(3), 451–455.

Muecke, U. P., Beckel, D., Bernard, A. B., Bieberle-Hütter, A., Graf, S., Infortuna, A., et al. (2008). Micro solid oxide fuel cells on glass ceramic substrates. Advanced Functional Materials,18(20), 1–11.

Kang, S., Heo, P., Lee, Y. H., Ha, J., Chang, I., & Cha, S. W. (2011). Low intermediate temperature ceramic fuel cell with Y-doped BaZrO3 electrolyte and thin film pd anode on porous substrate. Electrochemistry Communications,13(4), 374–377.

Ji, S., Cho, G. Y., Yu, W., Su, P. C., Lee, M. H., & Cha, S. W. (2015). Plasma-enhanced atomic layer deposition of nanoscale Yttria-stabilized zirconia electrolyte for solid oxide fuel cells with porous substrate. ACS Applied Materials & Interfaces,7(5), 2998–3002.

Yu, W., Ji, S., Cho, G. Y., An, J., & Cha, S. W. (2014). Atomic layer deposition of ultrathin blocking layer for low-temperature solid oxide Fuel cell on nanoporous substrate. Journal of Vacuum Science and Technology A,33(1), 01A145.

Ji, S., Chang, I., Cho, G. Y., Lee, Y. H., Shim, J. H., & Cha, S. W. (2014). Application of dense nano-thin platinum films for low-temperature solid oxide fuel cells by atomic layer deposition. International Journal of Hydrogen Energy,39(23), 12402–12408.

Han, E. D., Kim, B. H., & Seo, Y. H. (2018). Effect of nanochannel size of surface treated thru-hole alumina membrane in rejection of polar molecules. International Journal of Precision Engineering and Manufacturing,19(2), 287–292.

Chung, C. K., Tasi, C. H., & Wang, Z. W. (2019). Enhancement of surface roughness and growth morphology of nanoporous anodic alumina from commercially aluminum alloy 1050 using two-step electrochemical polishing. Journal of the Electrochemical Society,166(1), E498–E503.

Al-Haddad, A., Zhan, Z. B., Wang, C. L., Tarish, S., Vellacheria, R., & Lei, Y. (2015). Facile transferring of wafer-scale ultrathin alumina membranes onto substrates for nanostructure patterning. ACS Nano,9(8), 8584–8591.

Siddiqui, M. U., Arif, A. F. M., & Bashmal, S. (2016). Permeability-selectivity analysis of microfiltration and ultrafiltration membranes: Effect of pore size and shape distribution and membrane stretching. Membranes,6(3), 40.

O’Hayre, R., Cha, S. W., Colella, W., & Prinz, F. B. (1987). Fuel cell fundamentals (pp. 23–58). Hoboken: Wiley.

Ji, S., Chang, I., Lee, Y. H., Park, J., Paek, J. Y., Lee, M. H., et al. (2013). Fabrication of low-temperature solid oxide fuel cells with a nanothin protective layer by atomic layer deposition. Nanoscale research letters,8(1), 48.

Ji, S., Seo, H. G., Lee, S., Seo, J., Lee, Y., Tanveer, W. H., et al. (2017). Integrated design of a Ni thin-film electrode on a porous alumina template for affordable and high-performance low-temperature solid oxide fuel cells. RSC Advances,7, 23600–23606.

Pardon, G., Gatty, H. K., Stemme, G., van der Wijngaart, W., & Roxhed, N. (2013). Pt-Al2O3 dual layer atomic layer deposition coating in high aspect ratio nanopores. Nanotechnology,24(1), 015602.

Jiang, X., Huang, H., Prinz, F. B., & Bent, S. F. (2008). Application of atomic layer deposition of platinum to solid oxide fuel cells. Chemistry of Materials,20(12), 3897–3905.

Ji, S., Ha, J., Park, T., Kim, Y., Koo, B., Kim, Y. B., et al. (2016). Substrate-dependent growth of nanothin film solid oxide fuel cells toward cost-effective nanostructuring. International Journal of Precision Engineering and Manufacturing- Green Technology,3(1), 35–39.

Yu, W., Lee, Y., Lee, Y. H., Cho, G. Y., Park, T., Tanveer, W. H., et al. (2016). Performance enhancement of thin film LSCF cathodes by gold current collecting layer. International Journal of Precision Engineering and Manufacturing- Green Technology,3(2), 185–188.

Acknowledgements

This work was supported by the National Research Foundation of Korea Project (No. NRF-2018R1D1A1B07048082) and the Korea Institute of Civil Engineering and Building Technology Project (No. 20190129). The author would like to thank Professor Suk Won Cha at Seoul National University for sharing experimental equipment.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This paper was presented at PRESM2019.

Rights and permissions

About this article

Cite this article

Ji, S. Thickness Determination of a Solid Oxide Fuel Cell Blocking Layer Prepared by Atomic Layer Deposition Considering the Non-uniform Surface Geometry of Porous Substrate. Int. J. Precis. Eng. Manuf. 21, 1085–1090 (2020). https://doi.org/10.1007/s12541-020-00323-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-020-00323-x