Abstract

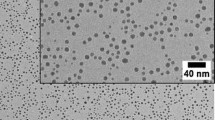

In the ultra-precision industry, physical and chemical coatings are used to provide functional properties to the surface. Especially, it is very important to examine the mechanical durability of polymer thin films with super hydrophobic properties. The mechanical durability of the thin film includes adhesion force and shear strength, and the latter can be measured with precise cutting. A sharp blade capable of changing cutting direction is used for cutting nano-thick films. Then, nano cutting method is used to calculate the shear strength by measuring the resistant forces when the blade cuts thin films simultaneously in the horizontal and vertical directions (slanted cutting). In this study, we prepared two super-hydrophobic fluoropolymers, p(PFDMA) (1H, 1H, 2H, 2H-perfluorodecyl methacrylate) thin film and p(V4D4-PFDMA-co-DVB) thin film, using initiated chemical vapor deposition method. Especially, p(V4D4-PFDMA-co-DVB) thin film was obtained by continuous deposition with V4D4 (1,3,5,7-tetravinyl-1,3,5,7-tetramethylcyclotetrasiloxane) and DVB (C6H4(CH=CH2)2, divinylbenzene) in order to improve its durability, and the abrasion test was performed to quantitatively check the durability. In order to qualitatively assess the durability, the thin film was cut with a customized precision-cutting tool, and the shear strength and adhesion force were analyzed. As a result, it was confirmed that the mechanical durability of p(V4D4-PFDMA-co-DVB) thin film has dramatically improved compared to p(PFDMA) thin film. In addition, the nano cutting theory was successfully verified to evaluate the mechanical properties of thin films.

Similar content being viewed by others

References

Chen, Z., Zhou, K., Lu, X., & Lam, Y. C. (2014). A review on the mechanical methods for evaluating coating adhesion. Acta Mechanica,225, 431–452.

Coclite, A. M., Shi, Y., & Gleason, K. K. (2013). Super-hydrophobic and oleophobic crystalline coatings by initiated chemical vapor deposition. Physics Procedia,46, 56–61.

Ozaydin-Ince, G., Coclite, A. M., & Gleason, K. K. (2012). CVD of polymeric thin films: applications in sensors, biotechnology, microelectronics/organic electronics, microfluidics, MEMS, composites and membranes. Reports on Progress in Physics,75, 40.

Asatekin, A., Barr, M. C., Baxamusa, S. H., Lau, K. K. S., Tenhaeff, W., Xu, J., et al. (2010). Designing polymer surfaces via vapor deposition. Materials Today,13, 26–33.

Groner, M. D., Fabreguette, F. H., Elam, J. W., & George, S. M. (2004). Low-temperature Al2O3 atomic layer deposition. Chemistry of Materials,16, 639–645.

Ritala, M., Kukli, K., Rahtu, A., Räisänen, P. I., Leskelä, M., Sajavaara, T., et al. (2000). Atomic layer deposition of oxide thin films with metal alkoxides as oxygen sources. Science,288, 319–321.

Pürçek, G., Bacaksız, E., & Miskioğlu, İ. (2008). Structure and nanomechanical properties of CdTe thin films. Journal of Materials Processing Technology,198, 202–206.

Li, X., & Bhushan, B. (2002). A review of nanoindentation continuous stiffness measurement technique and its applications. Materials Characterization,48, 11–36.

Tomastik, J., & Ctvrtlik, R. (2013). Nanoscratch test—A tool for evaluation of cohesive and adhesive properties of thin films and coatings. In EPJ web of conferences (Vol. 48).

Merchant, M. E. (1945). Mechanics of the metal cutting process. Journal of Applied Physics,16, 267.

Saito, F., Nishiyama, I., & Hyodo, T. (2009). Application of nano-cutting for mechanical characterization of materials. Materials Letters,63, 2257–2259.

Schey, J. A. (1999). Introduction to manufacturing processes. New York: McGraw-Hill Education.

Gleason, K. K. (2015). CVD polymers: Fabrication of organic surfaces and devices. New York: Wiley-VCH.

Lee, H. S., Kim, H., Lee, J. H., & Kwak, J. B. (2019). Fabrication of a conjugated fluoropolymer film using one-step iCVD process and its mechanical durability. Coatings,9(7), 430.

Kim, J.-H., & Park, S. K. (2014). “Hydrophobic perfluoropolymer thin-film encapsulation for enhanced stability of inverted polymer solar cells. Journal of the Korean Physical Society,65(9), 1448–1452.

Mao, Yu., & Gleason, K. K. (2006). Positive-tone nanopatterning of chemical vapor deposited polyacrylic thin films. Langmuir,22, 1795–1799.

Yoo, Y., You, J. B., Choi, W., & Im, S. G. (2013). A stacked polymer film for robust superhydrophobic fabrics. Polymer Chemistry,4, 1664.

Mao, S., Tsuge, S., Ohtani, H., Uchijima, S., & Kiyokawa, A. (1998). Determination of cross-linking reagent, divinylbenzene in polystyrene-type ion exchange resin precursors with chloromethyl substituents by pyrolysis-gas chromatography in aiding preliminary reduction of chlorine atoms in the samples. Polymer,39, 143–149.

Acknowledgements

This paper was supported by Korea Institute for Advancement of Technology (KIAT) grant funded by the Korea Government (MOTIE) (P0002092, The Competency Development Program for Industry Specialist) and the National Research Foundation of Korea (NRF) grant funded by the Korea government (Ministry of Science and ICT) (No. NRF-2018R1C1B5045726).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lee, J.H., Lee, H.S. & Kwak, J.B. Mechanical Characterization of Polymeric Thin Films Using Nano Cutting Method. Int. J. Precis. Eng. Manuf. 21, 1091–1097 (2020). https://doi.org/10.1007/s12541-020-00325-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-020-00325-9