Abstract

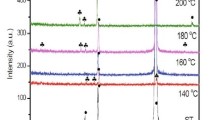

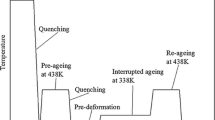

In this work, a cast alloy of Al–Zn–Mg was developed from aluminium from recycled beverage cans and zinc scraps from battery and the influence of age-hardening heat treatment of the alloy on mechanical properties and reliability analysis on the tensile strength was investigated. The cast Al–Zn–Mg alloy was subjected to age-hardening heat treatment at different times. The aluminium, cast alloy and age-hardened alloy were characterized using XRF, XRD and TEM. The mechanical properties were investigated using a hardness test, impact strength test and percentage elongation. Also, the tensile strength data were subjected to a reliability analysis using Weibull probability distribution. From the results, it shows that 24 h ageing time is enough to have optimum mechanical properties due to an increase in size of the stable MgZn2s phase particles. The reliability analysis shows that the alloy aged at 24 h has tensile strength value (229.72 MPa) in the range reported for Al–Zn–Mg alloy’s temper designations.

Similar content being viewed by others

References

Manjunath GK, Udaya Bhat K, Preetham Kumar G V., Ramesh MR.. Trans Indian Inst Met. 2018;71:1919.

Cui J, Roven HJ. 2010;20:2057.

Pontevedra V, Baffari D, Buffa G, et al.. Procedia Manuf. 2019;29:560.

Chiba R, Nakamura T, Kuroda M.. J Mater Process Technol. 2011;211:1878.

Ni H, Sun B, Jiang H, Ding W. Mater Sci Eng A. 2003;352:294.

Güley V, Ben Khalifa N, Tekkaya AE. Int J Mater Form. 2010;3:853.

Khamis SS, Lajis MA, Albert RAO. Procedia CIRP. 2015;26:477.

Shamsudin S, Lajis MA, Zhong ZW. 2016;40:256.

Mehtedi M El, Forcellese A, Mancia T, Simoncini M, Spigarelli S. Procedia CIRP. 2019;79:638.

Kazeem A, Badarulzaman NA, Fahmin W, Wan F. Mater Lett. 2019;7475:127067.

Farahany S, Ourdjini A, Idris MH, Takaloo A V., Thai LT.. 2013;52:208.

ASTM E8M-13a. 2014;(C):1.

Quinn JB, Quinn GD. 2010;26:135.

Arczewska P, Polak MA, Penlidis A. 2019;31(2).

Gorjan L, Ambrožič M. J Eur Ceram Soc. 2012;32:1221.

Muazu A, Yajid Muhamad Azizi Mat N, Ahmad. J Teknol. 2016;9:73.

Yatongchai C, Wren AW, Curran DJ, Hornez JC, Mark R T. 2013;21:95.

Wu D, Zhou J, Li Y. J Eur Ceram Soc. 2006;26:1099. https://doi.org/10.1016/j.jeurceramsoc.2005.01.044

Nie X, Zhang L, Du Y. Trans Nonferrous Met Soc China. 2014;24:2138.

LI B, PAN Q lin, CHEN C ping, YIN Z min. Trans Nonferrous Met Soc China (English Ed). 2016;26:2263.

ASTM E0008.

ASTM E384.

ASTM E 23-12c. Stand Test Methods Notched Bar Impact Test Met Mater.

ASM Met Handbook, Vol 02. 1997;2.

Aliyu IK, Saheb N, Hassan SF, Al-Aqeeli N. Metals (Basel). 2015;5:70.

Saboori A, Pavese M, Badini C, Fino P. Acta Metall Sin (English Lett). 2017;30:675.

Rosalie J, Hidetoshi Somekawa SA, Toshiji M. Philos Mag A. 2010;3355-3374:3355.

Gopala Krishna K, Sivaprasad K, Venkateswarlu K, Hari Kumar KC. Mater Sci Eng A. 2012;535:129.

Lin YC, Zhang JL, Liu G, Liang YJ. Mater Des. 2015;83:866.

Tang LEI, Xu G, Deng Y, Gan HAO, Ma A. JOM. 2017.

Sheng-dan LIU, Wen-bo L, Jian-guo T. 2013:4.

Acer E, Çadirli E, Erol H, Kirindi T, Gündüz M. Mater Sci Eng A. 2016;662:144.

Gür CH, Yildiz I. Mater Sci Eng A. 2004;382:395.

Raghunathan R, Prabhu KN, Hegde TG. Trans Indian Inst Met. 2014;67:997.

Abubakar M, Basheer U, Ahmad N. J Assoc Arab Univ Basic Appl Sci. 2017;24:81.

Fangli YU, Jianfeng Y, Yaohui XUE, Jun DU, Yuan LU. 2009;32:177.

Acknowledgements

Special thanks go to Directorate of Research, Innovation and Partnership, Bayero University, Kano, for giving financial support to this project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abubakar, M., Usman, M. Influence of Ageing Time on Mechanical Properties and Weibull Probability Distribution of Tensile Strength of Ternary Al–Zn–Mg Alloy Produced from Aluminium and Zinc Scrap. Trans Indian Inst Met 73, 1827–1836 (2020). https://doi.org/10.1007/s12666-020-01995-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-01995-9