Abstract

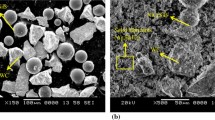

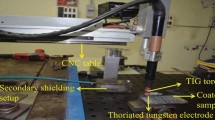

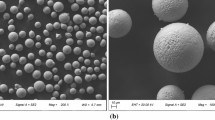

A nickel alloy matrix high-temperature self-lubricating coating (77.5 wt% (Ni–Cr–Mo–Al)–12.5 wt% Ag–10 wt% BaF2/CaF2) was prepared by plasma spraying technique. Results show that the Vickers microhardness of coating is (2.9 ± 0.5) GPa, and the average bonding strength is about (35.6 ± 0.5) MPa. The coating rubbing against Inconel 718 superalloy pin exhibits superior tribological performance with coefficient of friction (COF) of below 0.25 and wear rate of 8.2 × 10–5–15.2 × 10–5 mm3·N−1·m−1 at a wide temperature range from 25 to 800 °C, and the COF and the wear rate are slightly reduced with temperature increasing. The low COF and wear rate were attributed to the synergistic effects of Ag, BaF2/CaF2, Ag2MoO4 and BaMoO4.

Graphic abstract

Similar content being viewed by others

References

Tong WH, Zhao ZL, Wang J, Guo XM, Duan XH, Liu Y. Microstructure and property of laser cladding cobalt based alloy coatings on ductile cast iron. Chin J Rare Met. 2017;41(12):1386.

Guo YX, Liu QB, Zhou F. Microstructure and wear resistance of high-melting-point AlCrFeMoNbxTiW high-entropy alloy coating by laser cladding. Chin J Rare Met. 2017;41(12):1327.

Findik F. Latest progress on tribological properties of industrial materials. Mater Des. 2014;57:218.

Gao HH, Ding TT, Ma SJ, Wang P, Hou QY, Huang ZY. Microstructure and wear resistance of VC/tin-bronze coating deposite by plasma transferred arc surfacing. Chin J Rare Met. 2017;41(1):45.

Ozgun O, Gulsoy HO, Findik F, Yilmaz R. Microstructure and mechanical properties of injection molded Nimonic-90 superalloy parts. Powder Metall. 2012;55(5):413.

Blau PJ. Elevated-temperature tribology of metallic materials. Tribol Int. 2010;43(7):1203.

Wang WC. Application of a high temperature self-lubricating composite coating on steam turbine components. Surf Coat Technol. 2004;177(30):12.

Salman S, Topal A, Findik F. Performance improvement of Al-alloyed materials via plasma spray coating. Ind Lubr Tribol. 2008;60(1):4.

Sliney HE, Dellacorte C, Lukaszewicz V. The tribology of PS212 coatings and PM212 composites for the lubrication of titanium 6A1–4V components of a Stirling engine space power system. Tribol Trans. 1995;38(3):497.

Dellacorte C, Fellenstein JA. The effect of compositional tailoring on the thermal expansion and tribological properties of PS300: a solid lubricant composite coating. Tribol Trans. 1997;40(4):639.

Voevodin AA, Muratore C, Aouadi SM. Hard coatings with high temperature adaptive lubrication and contact thermal management: review. Surf Coat Technol. 2014;257:247.

Aouadi SM, Luster B, Kohli P, Muratore C, Voevodin AA. Progress in the development of adaptive nitride-based coatings for high temperature tribological applications. Surf Coat Technol. 2009;204(6):962.

Chen J, Zhao XQ, Zhou HD, Chen JM, An YL, Yan FY. HVOF-sprayed adaptive low friction NiMoAl–Ag coating for tribological application from 20 to 800 °C. Tribol Lett. 2014;56(1):55.

Niu MY, Bi QL, Yang J, Liu WM. Tribological performance of a Ni3Al matrix self-lubricating composite coating tested from 25 to 1000 °C. Surf Coat Technol. 2012;206(19–20):3938.

Liu XB, Meng XJ, Liu HQ, Shi GL, Wu SH, Sun CF, Wang MD, Qi LH. Development and characterization of laser clad high temperature self-lubricating wear resistant composite coatings on Ti–6Al–4V alloy. Mater Des. 2014;2014(55):404.

Xin BB, Yu YJ, Zhou JS, Wang LQ, Ren SF, Li Z. Effect of silver vanadate on the lubricating properties of NiCrAlY laser cladding coating at elevated temperatures. Surf Coat Technol. 2016;307:136.

Chen T, Song DF, Chen SQ. Microstructure and properties of Al–Fe–Si alloy under friction stir processing. Chin J Rare Met. 2019;43(12):1275.

Li F, Cheng J, Qiao ZH, Ma JQ, Zhu SY, Fu LC, Yang J, Liu WM. A nickel-alloy-based high temperature self-lubricating composite with simultaneously superior lubricity and high strength. Tribol Lett. 2013;49(3):573.

Cheng J, Li F, Zhu SY, Hao JY, Yang J, Li WS, Liu WM. High temperature tribological properties of a nickel-alloy-based solid-lubricating composite: effect of surface tribo-chemistry, counterpart and mechanical properties. Wear. 2017;386:39.

Cui S, Li WS, He L. Tribological behavior of a Ni–WS2 composite coating across wide temperature ranges. Rare Met. 2019;38(11):1078.

Zhao XQ, An YL, Hou GL, Zhou HD, Chen JM. Preparation and tribological properties of plasma sprayed nano and micro-structure alumina-reinforced CuAl composite coatings. Tribol Int. 2016;101:255.

Li WS, Fan XJ, Yang J, Zhu SY, Hu W, Sun Y. Preparation and tribological properties of Ni3Al matrix self-lubricating composite coating. Tribology. 2018;38(6):626.

Wang JY, Shan Y, Guo HJ, Li B, Wang WZ, Jia JH. Friction and wear characteristics of hot-pressed NiCr-Mo/MoO3/Ag self-lubrication composites at elevated temperatures up to 900 °C. Tribol Lett. 2015;59(3):48.

Zhang XH, Li XX, Liu WJ. Preparation and tribological behavior of electrodeposited Ni-W-GO composite coatings. Rare Met. 2019;38(7):695.

Zhu SY, Bi QL, Yang J, Liu WM. Tribological property of NiAl matrix composites with addition of BaMoO4. Tribol Lett. 2011;43(1):55.

Fang Y, Fan HZ, Song JJ, Zhang YS, Hu LT. Surface engineering design of Al2O3/Mo self-lubricating structural ceramics—Part II: Continuous lubrication effects of a three-dimensional lubricating layer at temperatures from 25 to 800 °C. Wear. 2016;360:97.

He B, Lei T, Zhuang JL. Microstructure and properties of aluminum alloy-ceramic gradient materials by laser deposition. Chin J Rare Met. 2019;43(4):95.

Kong LQ, Bi QL, Zhu SY, Yang J, Liu WM. Tribological properties of ZrO2, (Y2O3)–Mo–BaF2/CaF2, composites at high temperatures. Tribol Int. 2012;45(1):43.

Ouyang JH, Shi CC, Liu ZG, Wang YM, Wang YJ. Fabrication and high-temperature tribological properties of self-lubricating NiCr–BaMoO4 composites. Wear. 2015;330:272.

Zhu SY, Li F, Ma JQ, Cheng J, Yin B, Yang J, Qiao ZH, Liu WM. Tribological properties of Ni3Al matrix composites with addition of silver and barium salt. Tribol Int. 2015;84:118.

Acknowledgements

This study was financially supported by the International Science and Technology Cooperation Program of China (No. 2015DFR51090) and the National Program on Key Research Project of China (No. 2016YFE0111400).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, WS., Sun, Y., Hu, W. et al. Tribological properties of plasma-sprayed nickel alloy matrix self-lubricating coating at elevated temperatures. Rare Met. 40, 1844–1850 (2021). https://doi.org/10.1007/s12598-020-01426-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01426-0