Abstract

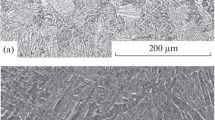

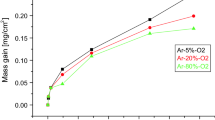

The structure, phase composition, and local chemical composition of half-finished products (rods) made from Ti–Al–Mo–Zr–Si- and Ti–Al–Mo–Zr–Sn–Si-based alloys additionally microalloyed with 0.4 wt % gadolinium have been studied in this work. The structure of the rod made from the Gd-alloyed Ti–Al–Mo–Zr–Si composition was found to be characterized by the presence of Gd2O3 gadolinium oxide particles. The structure of the rod made from the Gd-alloyed Ti–Al–Mo–Zr–Sn–Si composition, which contains tin as a low-melting element, is characterized by the presence of Gd–Sn–O complex oxide particles, whose cores and shells are Gd5Sn3 intermetallics and Gd2O3 gadolinium oxide, respectively. The formation of such particles in both alloys occurs at the stage of ingot solidification, and the particles remain in the materials at all stages of their subsequent treatment. The oxidation kinetics of the alloys upon isothermal holding in a temperature range of 600–800°С is studied depending on the structure of half-finished products. The oxidation processes of the Ti–Al–Mo–Zr–Sn–Si alloy are less intensive than those of the Ti–Al–Mo–Zr–Si alloy. The alloying with gadolinium up to 0.4 wt % leads to the accelerated oxidation of the tin-free alloy, which is due to the presence of Gd2O3 particles precipitated at grain boundaries and interfaces. The alloying of the tin-containing composition with gadolinium almost does not affect the oxidation kinetics at 600–700°С and slightly decelerates the oxidation at 750–800°С; this is related to the presence of the Gd–Sn–O oxide particles in the structure, which are uniformly distributed over the grain body. The laws of oxidation of both the compositions free from gadolinium and alloyed with gadolinium were determined. It was shown that the oxide film formed upon the oxidation of both alloys is multilayer and consists of alternating layers of aluminum and titanium oxides. In this case, the progressive growth of oxide film layers alters the film exfoliation owing to the high brittleness of aluminum oxides. The presence of gadolinium oxide particles in both alloys leads to the porosity of diffusion zone of the base metal upon oxidation.

Similar content being viewed by others

REFERENCES

N. F. Anoshkin and Yu. M. Sigalov, “Titanium alloys with enhanced heat resistance,” Tekhn. Legkikh Splavov, No. 1, 38–50 (2002).

O. S. Kashapov, A. V. Novak, N. A. Nochovnaya, and T. V. Pavlova, “State, problems and prospects of creating heat-resistant titanium alloys for gas turbine engine parts,” Trudy VIAM, No. 3 (2013).

Titanium and Titanium Alloys. Fundamentals and Applications, Ed. by C. Leyens and M. Peters (Wiley, Weinheim, 2003).

V. G. Antashev, N. A. Nochovnaya, T. V. Pavlova, and V. I. Ivanov, Heat Resistant Titanium Alloys. All Materials. Handbook, No. 3, 7–8 (2007).

R. A. Gaisin, V. M. Imayev, and R. M. Imayev, “Microstructure and mechanical properties of a near-α-titanium-alloy/TiB composite prepared in situ by casting and subjected to deformation and heat treatment,” Phys. Met. Metallogr. 119, 907–916 (2018).

H. Fu, Q. Xiao, and Y. Li, “A study of the microstructures and properties of Fe–V–W–Mo alloy modified by rare earth,” Mater. Sci. Eng., A 395, 281–287 (2005).

A. I. Khorev, “Basic study of alloying of titanium alloys with rare earth elements,” Vestn. Mashinostr., No. 11, 53–62 (2011).

I. A. Grushin, S. V. Skvortsova, K. S. Speranskii, A. A. Demakov, and N. A. Mamontova, “The effect of additional doping with gadolinium on the structure and properties of the experimental heat-resistant titanium alloy in cast and deformed states,” Titan, No. 1, 4–9 (2017).

M. Zhao, Z. Zhou, Q. Ding, M. Zhong, and K. Arshad, “Effect of rare earth elements on the consolidation behavior and microstructure of tungsten alloys,” J. Refract. Met. Hard Mater. 48, 19–23 (2015).

J. Hieda, M. Niinomi, M. Nakai, K. Cho, and S. Nagai, “Effect of oxide particles formed through addition of rare-earth metal on mechanical properties of biomedical α-type titanium alloy,” Mater. Trans. 54, 1361–1367 (2013).

S. Skvortsova, I. Grushin, O. Umarova, and K. Speranskiy, “Effect of Rare-earth element addition on structure of heatresistant Ti–6.5Al–4Zr–2.5Sn–2.4V–1Nb–0.5Mo–0.2Si titanium alloy,” MATEC Web Conf. 114, 02008 (2017).

V. A. Kaschuk and M. B. Svetlov, “The effect of small additions of rare earth metals and rhenium on the properties of titanium alloy VT5L,” Science. Thought, Kiev, 85–91 (1975).

N. A. Nochovnaya, A. I. Khorev, and A. Yakovlev, “Prospects for alloying titanium alloys with rare earth elements,” Metalloved. Term. Obr. Met., No. 8, 18–23 (2013).

S.V. Skvortsova, I. A. Grushin, K. A. Speranskiy, and E. V. Kavchenko, “Effect of heat treatment on the structure and properties of sheet semifinished products made of a heat-resistant alloy based on titanium and alloyed with rare-earth metal,” Russ. J. Non-Ferrous Met. 59, 157–162 (2018).

M. A. Popova, N. G. Rossina, N. A. Popov, and M. O. Leder, “Precipitation of oxide phases in titanium alloys with rare earth metals,” Lett. Mater. 7, 60–63 (2017).

B. G. Siemers, F. Brunke, J. Laukart, M. S. Hussain, J. Rösler, K. Saksl, B. Zahra, “Rare earth metals in titanium alloys—a systematic study,” Rare Earths 1, 281–292 (2012).

A. S. Bai, D. I. Lainer, E. N. Slesareva, and M. I. Tsypin, Oxidation of Titanium and Its Alloys (Metallurgiya, Moscow, 1970).

A. P. Kovalev, “Kinetics and basic laws of gas saturation of titanium alloys,” Nauchnye trudy (Vestnik MATI), No. 4, 335–339 (2001).

J. Dai, J. Zhu, C. Chen, and F. Weng, “High temperature oxidation behavior and research status of modifications on improving high temperature oxidation resistance of Ti-alloys and Ti-aluminides: A review,” J. Alloys Compd., 685, 784–798 (2016).

S. Frangini and A. Mignone, “Various aspects of the air oxidation behavior of a Ti6Al4V alloy at temperatures in the range 600–700°C,” J. Mater. Sci. 29, 714–720 (1994).

B. Sefer, Oxidation and Alpha-Case Phenomena in Titanium Alloys used in Aerospace Industry: Ti–6Al–2Sn–4Zr–2Mo and Ti–6Al–4V (Luleå University of Technology, 2014).

R. Gaddam, B. Sefer, R. Pederson, and M. -L. Antti, “Oxidation and alpha-case formation in Ti–6Al–2Sn–4Zr–2Mo alloy,” J. Mater. Charact., No. 99, 166–174 (2015).

Funding

This study was supported by the Russian Scientific Foundation (project no. 18-13-00220).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by N. Kolchugina

Rights and permissions

About this article

Cite this article

Popov, A.A., Leder, M.O., Karabanalov, M.C. et al. Analysis of the Microstructure, Phase Composition, and Oxidation Kinetics of Heat-Resistant Titanium Alloys with Gadolinium. Phys. Metals Metallogr. 121, 359–366 (2020). https://doi.org/10.1134/S0031918X20040110

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X20040110