Abstract

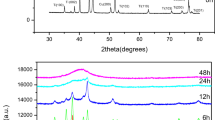

In this study, effects of morphology and chemical distribution of powder on mechanical properties was investigated in Al0.5CoCrCuFeNi high-entropy alloys produced via powder metallurgy. At the early stages of ball-milling, Cr-deficient large powder is flattened, while Cr-rich powder is fractured to small particles because of the flattening of ductile particles and fragmentation of hard particles at initial milling stage. However, with an increase in the milling duration, the Cr atoms were more uniformly distributed throughout the powders and the powders exhibited spherical shape with smooth surface. Moreover, as the ball-milling duration increased from 36 to 96 h, the Vickers hardness and compressive yield strength also increased from 433 Hv0.5 and 1166 MPa to 525 Hv0.5 and 1739 MPa, respectively. This was attributed to the spherical powders reducing as well as forming fine and uniform microstructures in sintered alloys. Also, the elemental uniformity suppressed the formation of dendritic-unfavorable carbides.

Graphic Abstract

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004)

E.P. George, D. Raabe, R.O. Ritchie, Nat. Rev. Mater. 4, 515 (2019)

S. Gorsse, M.H. Nguyen, O.N. Senkov, D.B. Miracle, Data Br. 21, 2664 (2018)

R. Sriharitha, B.S. Murty, R.S. Kottada, Intermetallics 32, 119 (2013)

M. Li, J. Gazquez, A. Borisevich, R. Mishra, K.M. Flores, Intermetallics 95, 110 (2018)

C.-J. Tong, Y.-L. Chen, J.-W. Yeh, S.-J. Lin, S.-K. Chen, T.-T. Shun, C.-H. Tsau, S.-Y. Chang, Metall. Mater. Trans. A 36, 881 (2005)

J. Hou, X. Shi, J. Qiao, Y. Zhang, P.K. Liaw, Y. Wu, Mater. Des. 180, 107910 (2019)

M.A. Hemphill, T. Yuan, G.Y. Wang, J.W. Yeh, C.W. Tsai, A. Chuang, P.K. Liaw, Acta Mater. 60, 5723 (2012)

M. Vaidya, G.M. Muralikrishna, B.S. Murty, J. Mater. Res. 34, 664 (2019)

W. Wang, B. Li, S. Zhai, J. Xu, Z. Niu, J. Xu, Y. Wang, Met. Mater. Int. 24, 1112 (2018)

J.M. Torralba, P. Alvaredo, A. García-Junceda, Powder Metall. 62, 84 (2019)

C. Suryanarayana, Prog. Mater Sci. 46, 1 (2001)

A. Raza, B. Kang, J. Lee, H.J. Ryu, S.H. Hong, Mater. Des. 145, 11 (2018)

J.B. Fogagnolo, F. Velasco, M.H. Robert, J.M. Torralba, Mater. Sci. Eng., A 342, 131 (2003)

Y. Xie, H. Cheng, Q. Tang, W. Chen, W. Chen, P. Dai, Intermetallics 93, 228 (2018)

R. Anand Sekhar, S. Samal, N. Nayan, S.R. Bakshi, J. Alloys Compd. 787, 123 (2019)

Z. Fu, W. Chen, Z. Jiang, B.E. MacDonald, Y. Lin, F. Chen, L. Zhang, E.J. Lavernia, Powder Metall. 61, 106 (2018)

T.H. Courtney, Mechanical Behavior of Materials, 2nd edn. (Waveland Press, Long Grove, 2000), pp. 181–186

S. Nam, J.Y. Hwang, J. Jeon, J. Park, D. Bae, M.J. Kim, J.-H. Kim, H. Choi, J. Mater. Res. 34, 720 (2019)

J.S. Benjamin, T.E. Volin, Metall. Trans. 5, 1929 (1974)

H.J. Fecht, E. Hellstern, Z. Fu, W.L. Johnson, Metall. Trans. A 21, 2333 (1990)

Z.Q. Guan, T. Pfullmann, M. Oehring, R. Bormann, J. Alloys Compd. 252, 245 (1997)

F.R. de Boer, R. Boom, W.C.M. Mattens, A.R. Miedema, A.K. Niessen, Cohesion in Metals: Transition Metal Alloys (North-Holland, Amsterdam, 1988)

H.F. Sheng, M. Gong, L.M. Peng, Mater. Sci. Eng., A 567, 14 (2013)

S. Nam, M.J. Kim, J.Y. Hwang, H. Choi, J. Alloys Compd. 762, 29 (2018)

Ł. Rogal, Z. Szklarz, P. Bobrowski, D. Kalita, G. Garzeł, A. Tarasek, M. Kot, M. Szlezynger, Met. Mater. Int. 25, 930 (2019)

P. Sathiyamoorthi, J. Basu, S. Kashyap, K.G. Pradeep, R.S. Kottada, Mater. Des. 134, 426 (2017)

S. Praveen, A. Anupam, R. Tilak, R.S. Kottada, Mater. Chem. Phys. 210, 57 (2018)

X.F. Wang, Y. Zhang, Y. Qiao, G.L. Chen, Intermetallics 15, 357 (2007)

S.S. Sohn, A. Kwiatkowski da Silva, Y. Ikeda, F. Körmann, W. Lu, W.S. Choi, B. Gault, D. Ponge, J. Neugebauer, D. Raabe, Adv. Mater. 31, 1807142 (2019)

Z. Fu, W. Chen, S. Fang, D. Zhang, H. Xiao, D. Zhu, J. Alloys Compd. 553, 316 (2013)

S. Guo, C.T. Liu, Prog. Nat. Sci. Mater. Int. 21, 433 (2011)

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, P.K. Liaw, Adv. Eng. Mater. 10, 534 (2008)

H.P. Klug, L. Alexander, X-ray Diffraction Procedures for Poly-Crystalline and Amorphous Materials, 2nd edn. (Wiley, New York, 1974), pp. 618–708

N. Kumar, M. Komarasamy, P. Nelaturu, Z. Tang, P.K. Liaw, R.S. Mishra, JOM 67(5), 1007 (2015)

L.J. Gibson, M.F. Ashby, Cellular Solids: Structure and Properties (Cambridge University Press, Cambridge, 1997), pp. 183–189

K. Miyake, Y. Hirata, T. Shimonosono, S. Sameshima, Materials 11, 1137 (2018)

C. Yang, M.D. Zhu, X. Luo, L.H. Liu, W.W. Zhang, Y. Long, Z.Y. Xiao, Z.Q. Fu, L.C. Zhang, E.J. Lavernia, Scr. Mater. 139, 96 (2017)

Acknowledgements

This study was financially supported by the National Research Foundation (NRF) of Korea and funded by Ministry of Science, ICT (MSIT; 2015R1A5A7037615), and the Ministry of Trade, Industry and Energy (MOTIE) and Korea Institute for Advancement of Technology (KIAT) through the International Cooperative R&D program (P0006837). This research was also financially supported from the Civil-Military Technology cooperation program (No. 18-CM-MA-15).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nam, S., Shin, S.E., Kim, JH. et al. Effect of Powder Morphology and Chemical Distribution on Properties of Multicomponent Alloys Produced Via Powder Metallurgy. Met. Mater. Int. 26, 1385–1393 (2020). https://doi.org/10.1007/s12540-020-00769-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00769-8