Abstract

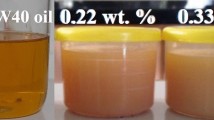

In present research AZ91D/SiC composites were developed using advanced vacuum assisted stir casting process. The tribological properties of AZ91D/SiC composites under dry, oil and nanofluids lubricating conditions were investigated. The nanofluids were prepared by adding the silicon carbide (SiC) nanoparticles to the soluble oil with different weight percentages (1 wt.%, 1.5 wt.%, 2.0 wt.%) for experimentation. The mixing of nanoparticles with base fluid improves the tribological and thermal properties of fluids as the nanoparticles possess higher thermal conductivity than base fluids. The thermal conductivity of SiC nanofluids was evaluated. The wear surfaces under different lubricating conditions (dry, oil and nanofluids) were also analyzed with FESEM. The findings of the study reveal that there was a remarkable enhancement in tribological properties (wear and coefficient of friction) when SiC nanoparticles were added to soluble oil. Furthermore, the selected samples were analyzed using energy-dispersive X-ray spectroscopy (EDS), scanning electron microscope (SEM).

Similar content being viewed by others

References

Campbell FC (ed) (2012) Lightweight materials: understanding the basics. ASM International

Wang JJ, Guo JH, Chen LQ (2006) TiC/AZ91D composites fabricated by in situ reactive infiltration process and its tensile deformation. Trans Nonferrous Metals Soc China 16(4):892–896

Singh N, Mir IU, Raina A, Anand A, Kumar V, Sharma SM (2018) Synthesis and tribological investigation of Al-SiC based nano hybrid composite. Alex Eng Journal 57(3):1323–1330

Aatthisugan I, Rose AR, Jebadurai DS (2017) Mechanical and wear behaviour of AZ91D magnesium matrix hybrid composite reinforced with boron carbide and graphite. J Magnes Alloys 5(1):20–25

Singh H, Haq MI, Raina A (2019) Dry sliding friction and wear behaviour of AA6082-TiB 2 in situ composites. Silicon 9:1–1

Haq MI, Anand A (2019) Friction and wear behavior of AA 7075-Si 3 N 4 composites under dry conditions: effect of sliding speed. Silicon 11(2):1047–1053

Haq MI, Anand A (2018) Dry sliding friction and wear behavior of AA7075-Si 3 N 4 composite. Silicon 10(5):1819–1829

Ahmadkhaniha D, Sohi MH, Salehi A, Tahavvori R (2016) Formations of AZ91/Al2O3 nano-composite layer by friction stir processing. J Magnes Alloys 4(4):314–318

Ponappa K, Aravindan S, Rao PV (2013) Influence of Y2O3 particles on mechanical properties of magnesium and magnesium alloy (AZ91D). J Compos Mater 47(10):1231–1239

Yuan QH, Fu DM, Zeng XS, Yong LIU (2017) Fabrication of carbon nanotube reinforced AZ91D composite with superior mechanical properties. Trans Nonferrous Metals Soc China 27(8):1716–1724

Hashimoto Y, Hino M, Mitooka Y, Murakami K, Kanadani T (2016) Effects of fixing carbon nanoparticle to AZ91D magnesium alloy chip surface on thixomold forming. Mater Trans 57(2):183–187

Chen L, Zhao Y, Hou H, Zhang T, Liang J, Li M, Li J (2019) Development of AZ91D magnesium alloy-graphene nanoplatelets composites using thixomolding process. J Alloys Compd 78:359–374

Yuan QH, Qiu ZQ, Zhou GH, Zeng XS, Luo L, Rao XX, Ding Y, Liu Y (2018) Interfacial design and strengthening mechanisms of AZ91 alloy reinforced with in-situ reduced graphene oxide. Mater Charact 138:215–228

Wang CR, Deng KK, Bai Y (2019) Microstructure, and mechanical and wear properties of Grp/AZ91 magnesium matrix composites. Materials 12(7):1190

Selvakumar N, Narayanasamy P (2016) Optimization and effect of weight fraction of MoS2 on the tribological behavior of Mg-TiC-MoS2 hybrid composites. Tribol Trans 59(4):733–747

Aravindan S, Rao PV, Ponappa K (2015) Evaluation of physical and mechanical properties of AZ91D/SiC composites by two step stir casting process. J Magnes alloys 3(1):52–62

Balasubramanian I, Maheswaran R, Manikandan V, Patil N, Raja MA, Singari RM (2018) Mechanical characterization and machining of squeeze cast AZ91D/SiC magnesium based metal matrix composites. Procedia Manuf 20:97–105

Khatkar SK, Suri NM, Kant S (2018) A review on mechanical and tribological properties of graphite reinforced self lubricating hybrid metal matrix composites. Rev Adv Mater Sci 56(1):1–20

Girish BM, Satish BM, Sarapure S, Somashekar DR, Basawaraj (2015) Wear behavior of magnesium alloy AZ91 hybrid composite materials. Tribol Trans 58(3):481–489

Daniel SA, Sakthivel M, Gopal PM, Sudhagar S (2018) Study on tribological behaviour of Al/SiC/MoS 2 hybrid metal matrix composites in high temperature environmental condition. Silicon 10(5):2129–2139

Huang W, Hou B, Pang Y, Zhou Z (2006) Fretting wear behavior of AZ91D and AM60B magnesium alloys. Wear 260(11–12):1173–1178

Chen TJ, Ma Y, Li B, Li YD, Hao Y (2009) Effects of processing parameters on wear behaviors of thixoformed AZ91D magnesium alloys. Mater Des 30(2):235–244

Xia Y, Jia Z, Jia J (2009) Tribological behavior of AZ91D magnesium alloy against SAE52100 steel under ionic liquid lubricated conditions. In Advanced tribology 896-898

Huang W, Lin Q, Zhang X (2011) Investigation of tribological properties of magnesium alloys under dry sliding and lubrication condition. P I Mech Eng J-J Eng 225(1):35–42

Mehta DS, Masood SH, Song WQ (2004) Investigation of wear properties of magnesium and aluminum alloys for automotive applications. J Mater Process Technol 155:1526–1531

Singh H, Bhowmick H (2020) Lubrication characteristics and wear mechanism mapping for hybrid aluminium metal matrix composite sliding under surfactant functionalized MWCNT-oil. Tribol Int 145:106152

Singh H, Bhowmick H (2018) Tribological behaviour of hybrid AMMC sliding against steel and cast iron under MWCNT-oil lubrication. Tribol Int 127:509–519

Das SK, Putra N, Thiesen P, Roetzel W (2003) Temperature dependence of thermal conductivity enhancement for nanofluids. J Thermophys Heat Transf 125(4):567–574

Thakur A, Manna A, Samir S (2019) Multi-response optimization of turning parameters during machining of EN-24 steel with SiC nanofluids based minimum quantity lubrication. Silicon 12(1):71–85

Chinas-Castillo F, Spikes HA (2003) Mechanism of action of colloidal solid dispersions. J Tribol 125(3):552–557

Pramanik A, Basak A, Nomani J, Littlefair G, Islam MN, Anandakrishnan V(2015) Weldability and machinability of duplex stainless steel. In Stainless steel: microstructure, mechanical properties and methods of application 207–238

Jiao D, Zheng S, Wang Y, Guan R, Cao B (2011) The tribology properties of alumina/silica composite nanoparticles as lubricant additives. Appl Surf 257(13):5720–5725

Qiu S, Zhou Z, Dong J, Chen G (2001) Preparation of Ni nanoparticles and evaluation of their tribological performance as potential additives in oils. J Tribol 123(3):441–443

Wu YY, Tsui WC, Liu TC (2007) Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 262(7–8):819–825

Sunqing Q, Junxiu D, Guoxu C (1999) Tribological properties of CeF3 nanoparticles as additives in lubricating oils. Wear 230(1):35–38

Stachowiak GW, Batchelor AW (2001) Engineering tribology2nd edn. Butterworth- Heinemann

Xia ZH, Li LI, Dong WE, Liu XX, Wu CW (2018) Effect of hybrid ratio on friction and wear behavior of AZ91D matrix nanocomposites under oil lubricated conditions. Trans Nonferrous Metals Soc China 28(3):440–450

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kharb, S.S., Khatkar, S.K., Charak, A. et al. Tribological Investigation of AZ91/SiC Magnesium Hybrid Composite under Dry, Oil and Nanofluids Lubricating Conditions. Silicon 13, 1313–1323 (2021). https://doi.org/10.1007/s12633-020-00520-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-020-00520-3