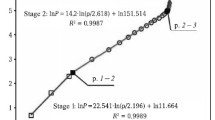

We perform the analysis of the available empirical compaction equations for fine-fraction materials. By modeling separate stages of the process of compaction for selected groups of materials, we reveal the advantages and drawbacks restricting the fields of their possible applications. It is shown that the compaction equation proposed at the Z. Nekrasov Institute of Ferrous Metallurgy of the NAS of Ukraine (IFM) is the only dependence that can be successfully applied to fine-fraction materials of the mining and metallurgical complex (MMC). The necessity of subsequent improvement of the indicated equation is substantiated.We propose two compaction equations whose joint application enables one to predict the relationship between the pressure and the degree of compaction in the process of briquetting within the technological range of pressures. These equations allow one to identify the stages of pressing and study the factors affecting the process. They can be also used to optimize the technological conditions of briquetting of materials of the MMC and to increase the reliability of determination of the power-and-force parameters of the process of pressing.

Similar content being viewed by others

References

B. M. Ravich, Briquetting of Ores [in Russian], Nedra, Moscow (1982).

V. V. Ozhogin, Foundations of the Theory and Technology of Briquetting of Milled Raw Materials for Metallurgy [in Russian], Azov-Region State Technical University, Mariupol, (2010).

B. N. Maimur, Development of works on the technology and equipment for the process of briquetting of finely divided raw materials and industrial wastes at the Institute of Ferrous Metallurgy, in: Fundamental and Applied Problems of Ferrous Metallurgy [in Russian], Institute of Ferrous Metallurgy, NAS of Ukraine, Dnepropetrovsk (2014), pp. 329 – 338.

A. Yu. Khudyakov, S. V. Vashchenko, K. V. Baiul, and Yu. S. Semenov, “Kaolin raw material briquetting for lump chamote production,” Refract. Ind. Ceram., 59(4), 333 – 337 (2018).

S. V. Vashchenko, A. Yu. Khudyakov, K. V. Baiul, and Yu. S. Semenov, “Selecting the batch composition in briquetting,” Steel Transl., 48(8), 509 – 512 (2018).

K. V. Baiul, A. T. Lebed’, S. V. Vashchenko, and A. Yu. Khudyakov, A hydraulic unit for the protection of a rolling press against overloads, Metallurg. Gornorud. Promyshl., No. 7, 159 – 164 (2018).

R. Ya. Popil’skii and Yu. E. Pivinskii, Compaction of Powder Ceramic Masses [in Russian], Metallurgy, Moscow (1983).

T. Comoglu, An overview of compaction equations, J. Fac. Pharm. Ankara,36(2), 123 – 133 (2007).

M. Yu. Bal’shin, Scientific Foundations of Powder and Fiber Metallurgy [in Russian], Metallurgy, Moscow (1972).

I. Klevan, Compression Analysis of Pharmaceutical Powders: Assessment of Mechanical Properties and Tablet Manufacturability Prediction, Ph. D. Thesis, University of Tromso, Tromso, Norway (2011).

P. J. Denny, “Compaction equations: a comparison of the Heckel and Kawakita equations,” Powder Technol., 127(2), 162 – 172 (2002).

S. Mallick, S. K. Pradhan, M. Chandran, et al., “Study of particle rearrangement, compression behavior, and dissolution properties after melt dispersion of ibuprofen, Avicel and Aerosil,” Results Pharma Sci., No. 1, 1 – 10 (2011).

R. J. Roberts, R. C. Rowe, and K. Kendal, “Brittle-ductile transitions in die compaction of sodium chloride,” Chem. Eng. Sci., 44(8), 1647 – 1651 (1989).

A. Z. Isagulov and V. Yu. Kulikov, “Construction of the compaction equation for sand-tar mixtures and their rheological models,” Izv. Vyssh. Uchebn. Zaved., Chern. Metallurg., No. 6, 52 – 56 (2007).

G. Bockstiegel, Modern developments in powder metallurgy, in: Proc. of the Internat. Powder Metall. Conf., Plenum, New York (1966), Vol. 1, pp. 155 – 187.

É. S. Dvilis, Regularities of the Processes of Consolidation of Powder Systems under Variable Conditions of Deformation and Physical Actions [in Russian], Doctoral-Degree Thesis (Physics and Mathematics), Tomsk Polytechnic University, Tomsk (2014).

P. Cardei and I. Gageanu, “A critical analysis of empirical formulas describing the phenomenon of compaction of the powders,” J. Modern Technol. Eng., 2(1), 1 – 20 (2017).

S. Mani, L. G. Tabil, and S. Sokhansanj, “An overview of compaction of biomass grinds,” Powder Hand. Process., 15(2), 1 – 9 (2003).

N. A. Tsytovich, Soil Mechanics [in Russian], Vysshaya Shkola, Moscow (1983).

G. A. Libenson, V. Yu. Lopatin, and G. V. Komarnitskii, Processes in Powder Metallurgy, Vol. 2: Formation and Sintering [in Russian], MISIS, Moscow (2002).

R. P. Feynman, R. B. Leighton, and M. Sands, The Feynman Lectures on Physics, Vol. 4, CalTech, Pasadena (2012).

R. M. German, Powder Metallurgy and Particulate Materials Processing, Metal Powder Industries Federation, Princeton (2005).

G. M. Zhdanovich, Theory of Pressing of Metallic Powders [in Russian], Metallurgiya, Moscow (1969).

A. K. Karklit, A. P. Losev, S. A. Losev, et al., Production of Refractory Materials by the Semidry Method [in Russian], Metallurgiya, Moscow (1981).

N. D. Titov and Yu. A. Stepanov, Technology of Casting Production [in Russian], Mashinostroenie, Moscow (1974).

V. F. Babkov and V. M. Bezruk, Foundations of Soil Sciences and Soil Mechanics [in Russian], Vysshaya Shkola, Moscow (1976).

P. V. Klassen and I. G. Grishaev, Foundations of the Granulation Technique (Processes and Equipment in Chemical and Petroleum- Chemical Technologies) [in Russian], Khimiya, Moscow (1982).

D. Hooper, F. C. Clarke, J. C. Snowden, et al., “A modern approach to the Heckel equation: the effect of compaction pressure on the yield pressure of ibuprofen and its sodium salt,” J. Nanomed. Nanotechnol., 7(3), 1 – 6 (2016).

P. J. Denny, “Compaction equations; a comparison of the Heckel and Kawakita equations,” Powd. Technol., 127(2), 162 – 172 (2002).

L. Pauling, General Chemistry, Dover, New York (1988).

P. Yadav and A. K. Sahdev, “Physics of tablet with compaction and compression process for novel drug dosage form,” Int. J. Adv. Sci. Res., 3(4), 28 – 34 (2018).

H. R. Hafizpour and M. Khoeini, “Investigation on the consolidation behavior of aluminum/nano-SiC composite powders using nonlinear compaction equation,” J. Amer. Sci., 7(6), 1258 – 1262 (2011).

N. F. Kunin and B. D. Yurchenko, “Regularities of pressing of the powders of various materials,” Poroshk. Metall., No. 6, 3 – 10 (1963).

R. M. German and S. J. Park, Mathematical Relations in Particulate Materials Processing: Ceramics, Powder Metals, Cermets, Carbides, Hard Materials, and Minerals, Wiley, New York (2008).

D. H. Choi, N. A. Kim, K. R. Chu, et al., “Material properties and compressibility using Heckel and Kawakita equation with commonly used pharmaceutical excipients,” J. Pharmaceut. Invest., 40, No. 4, 237 – 244 (2010).

V. A. Yakovlev, Kinetics of Enzyme Catalysis [in Russian], Nauka, Moscow (1965).

M. J. Adams, M. A. Mulliier, and J. P. Seville, “Agglomerate strength measurement using a uniaxial confined compression test,” Powder Technol., 78(1), 5 – 13 (1994).

S. F. Yap, M. J. Adams, and J. P. K. Seville, “Single and bulk compression of pharmaceutical excipients: Evaluation of mechanical properties,” Powder Technol., 185(1), 1 – 10 (2008).

P. Adapa, L. Tabil, and G. Schoenau, “Compression characteristics of selected ground agricultural biomass,” Agricult. Eng. Int.: the CIGR E-journal, XI, Manuscript 1347 (June, 2009).

R. Panelli and F. A. Filho, “A study of a new phenomenological compacting equation,” Powder Technol., 114, 255 – 261 (2001).

R. D. Ge, “Constitutive model for the hot pressing of powders,” J. Mater. Sci. Technol., No. 10, 374 – 380 (1995).

X. P. Chen, H. Nomura, and Y. Maeda, “Analysis of green sand compaction process applying Cooper – Eaton model,” J. Japan Foundry Soc., 75(1), 35 – 41 (2003).

I. N. Popescu and R. Vidu, “Compaction behavior modelling of metal-ceramic powder mixtures,” Sci. Bull. Valahia Univ. Mater. Mech., 16(14), 28 – 37 (2018).

P. Shivanand and O. I. Sprockel, “Compaction behavior of cellulose polymers,” Powder Technol., 69(2), 177 – 184 (1992).

J. M. Sonnergaard, “Investigation of a new mathematical model for compression of pharmaceutical powder,” Eur. J. Pharmaceut. Sci.,14, 149 – 157 (2001).

I. Shapiro and J. M. Sonnergaard, “Compaction of powders X. Development of a general compaction equation,” Adv. Powder Metall. Part. Mater., 3, 229 – 243 (1993).

S. Chen, J. Zhu, and X. Qi, “A new mathematical equation for the evaluation of the compression behavior of pharmaceutical materials,” Acta Pharmaceut. Sinica, 47(10), 1384 – 1388 (2012).

M. B. Shtern, G. G. Serdyuk, L. A. Maksimenko, et al., Phenomenological Theories of Compaction of Powders [in Russian], Naukova Dumka, Kiev (1982).

I. I. Eliseeva and M. M. Yuzbashev, General Theory of Statistics [in Russian], Finansy Statistika, Moscow (2004).

F. Eirich, Rheology. Theory and Applications, Academic Press, New York (1956).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 12, pp. 37 – 46, December, 2019.

Rights and permissions

About this article

Cite this article

Khudyakov, A.Y., Vashchenko, S.V. Analysis of Known Dependences and the Construction of New Compaction Equations for the Fine-Fraction Materials of the Mining and Metallurgical Complex. Refract Ind Ceram 60, 618–626 (2020). https://doi.org/10.1007/s11148-020-00417-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-020-00417-z