Abstract

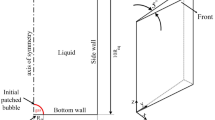

In this work, we study the transition from squeezing to dripping during the formation of bubbles in a capillary T-junction in conditions relevant to microgravity. The junction is formed by two perpendicular cylinders of equal section (1mm of internal diameter). The capillary number Ca (based on the continuous phase) is used as the key parameter of the study. For the range of Ca covered in this paper, the same two common bubble formation mechanisms as the ones described in the related literature have been observed: squeezing regime at low Ca and dripping regime for higher Ca. This paper provides a new value of the critical Ca for the transition from squeezing to dripping. This value has been obtained with two independent approaches, experimentally and numerically. Experimental photographs have been used to determine the value of Ca at which a gap appears between the forming bubble and the capillary’s wall, as an evidence of the activation of the shearing mechanism related to the dripping regime. Additionally, the dependence of the bubble volume on the capillary number and the gas/liquid flow rate ratio has been analysed. In this work, we also propose a new numerical approach, complementary to the experimental one, carried out with the Computational Fluid Dynamics solver ANSYS Fluent v15.0.7. Numerical simulations have been performed to study the geometry and the behaviour of the gas-liquid interface during the cycle of bubble formation. Upstream the T-junction, as the fluctuation in pressure decreases, the vertical movement of the rear meniscus (gas-liquid interface in contact with the solid vertical capillary) also decreases, and the shear stresses begins to play an active role until overcoming the squeezing mechanism. Numerical simulations presented in this paper support the experimental observations, confirming that Computational Fluid Dynamics studies can be a useful tool to improve the experimental knowledge.

Similar content being viewed by others

Change history

09 July 2020

The original version of this article unfortunately contained mistakes introduced during the production process.

In the caption of Fig.��9, ���|phic��� should be read as �����c���.

References

Abate, A.R., Pascaline, M., van Steijn, V., Weitza, D.A.: Experimental validation of plugging during drop formation in a T-junction. Lab Chip 12, 1516–1521 (2012). https://doi.org/10.1039/C2LC21263C

ANSYS Academic Research: Release 15.0,7, Help System. ANSYS, Inc. (2014)

Arias, S., González-Cinca, R.: Analysis of the characteristic lengths in the bubble and slug flow regimes generated in a capillary T-junction. Int. J. Multiph. Flow 87, 167–174 (2016). https://doi.org/10.1016/j.ijmultiphaseflow.2016.09.011

Arias, S., Montlaur, A.: Numerical study and experimental comparison of two-phase flow generation in a T-junction. AIAA J. 55(5), 1565–1574 (2017). https://doi.org/10.2514/1.J055387

Arias, S., Montlaur, A.: Influence of contact angle boundary condition on CFD simulation of T-junction. Microgravity Sci. Technol. 30(4), 435–443 (2018). https://doi.org/10.1007/s12217-018-9605-x

Arias, S., Ruiz, X., Ramírez-Piscina, L., Casademunt, J., González-cinca, R.: Experimental study of a microchannel bubble injector for microgravity applications. Microgravity Sci. Technol. 21, 107–118 (2009). https://doi.org/10.1007/s12217-008-9060-1

Arias, S., González-Cinca, R., Ruiz, X., Ramírez-Piscina, L., Casademunt, J.: Characterization of the performance of a minibubble generator in conditions relevant to microgravity. Colloids Surfaces A Physicochem. Eng. Aspects. 365, 52–57 (2010). https://doi.org/10.1016/j.colsurfa.2010.03.004

Arias, S., Legendre, D., González-Cinca, R.: Numerical simulation of bubble generation in a T-junction. Computers and Fluids 56, 49–60 (2012). https://doi.org/10.1016/j.compfluid.2011.11.013

Christopher, G.F., Noharuddin, N.N., Taylor, J.A., Anna, S.L.: Experimental observations of the squeezing-to-dripping transition in T-shaped microfluidic junctions. Phys. Rev. E 78(3), 036317 (2008). https://doi.org/10.1103/PhysRevE.78.036317

De Menech, M., Garstecki, P., Jousse, F., Stone, H.A.: Transition from squeezing to dripping in a microfluidic T-shaped junction. J. Fluid Mech. 595, 141–161 (2008). https://doi.org/10.1017/S002211200700910X

Fu, T., Ma, Y.: Bubble formation and breakup dynamics in microfluidic devices: a review. Chem. Eng. Sci. 135, 343–372 (2015). https://doi.org/10.1016/j.ces.2015.02.016

Garstecki, P., Fuerstman, M.J., Stone, H.A., Whitesides, G.M.: Formation of droplets and bubbles in a microfluidic T-junction-scaling and mechanism of break-up. Lab Chip 6, 437–446 (2006). https://doi.org/10.1039/b510841a

Guo, F., Chen, B.: Numerical study on Taylor bubble formation in a micro-channel T-junction using VOF method. Microgravity Sci. Technol. 21, 51–58 (2009). https://doi.org/10.1007/s12217-009-9146-4

Li, X.-B., Li, F.-C., Yang, J.-C., Kinoshita, H., Oishi, M., Oshima, M.: Study on the mechanism of droplet formation in T-junction microchannel. Chem. Eng. Sci. 69, 340–351 (2012). https://doi.org/10.1016/j.ces.2011.10.048

Liu, H., Zhang, Y.: Droplet formation in a T-shaped microfluidic junction. J. App. Phys. 106, 034906 (2009). https://doi.org/10.1063/1.3187831

Malekzadeh, S., Roohi, E.: Investigation of different droplet formation regimes in a T-junction microchannel using the VOF technique in openFOAM. Microgravity Sci. Technol. 27, 231–243 (2015). https://doi.org/10.1007/s12217-015-9440-2

Nunes, J.K., Tsai, S.S.H., Wan, J., Stone, H.A.: Dripping and jetting in microfluidic multiphase flows applied to particle and fibre synthesis. J. Phys. D Appl. Phys 46, 114002 (2013). https://doi.org/10.1088/0022-3727/46/11/114002

Oishi, M., Kinoshita, H., Fujii, T., Oshima, M.: Confocal Micro-PIV measurement of droplet formation in a T-shaped micro-junction. J. Phys. Conf. Ser. 147(1), 012061 (2009). https://doi.org/10.1088/1742-6596/147/1/012061

Rezkallah, K.S.: Weber number based flow-pattern maps for liquid-gas flows at microgravity. Int. J. Multiph. Flow 22(6), 1265–1270 (1996). https://doi.org/10.1016/0301-9322(96)00047-X

Ronshin, F.V., Dementyev, Y. u. A., Chinnov, E.A., Cheverda, V.V., Kabov, O.A.: Experimental investigation of adiabatic and pressure drop in slit microchannel. Microgravity Sci. Technol. 31, 693–707 (2019). https://doi.org/10.1007/s12217-019-09747-1

Suo, M., Griffith, P.: Two-phase flow in capillary tubes. J. Basic Eng. 86, 576–582 (1964). https://doi.org/10.1115/1.3653176

Thorsen, T., Roberts, R.W., Arnold, F.H., Quake, S.R.: Dynamic pattern formation in a vesicle-generating microfluidic device. Phys. Rev. Lett. 86(18), 4163–4167 (2001). https://doi.org/10.1103/PhysRevLett.86.4163

Utada, A.S., Chu, L.-Y., Fernandez-Nieves, A., Link, D.R., Holtze, C., Weitz, D.A.: Dripping, jetting, drops, and wetting: the magic of microfluidics. MRS Bulletin 32(9), 702–708 (2007). https://doi.org/10.1557/mrs2007.145

van der Graaf, S., Nisisako, T., Schroën, C.G.P.H., van der Sman, R.G.M., Boom, R.M.: Lattice Boltzmann simulations of droplet formation in a T-shaped microchannel. Langmuir 22(9), 4144–4152 (2006). https://doi.org/10.1021/la052682f

van Steijn, V., Chris, R., Kleijn, C.R., Kreutzer, M.T.: Flows around confined bubbles and their importance in triggering pinch-off. Phys. Rev. Lett. 103, 214501–4 (2009). https://doi.org/10.1103/PhysRevLett.103.214501

van Steijn, V., Chris, R., Kleijn, C.R., Kreutzer, M.T.: Predictive model for the size of bubbles and droplets created in microfluidic T-junctions. Lab Chip 10, 2513–2518 (2010). https://doi.org/10.1039/c002625e

Xu, J.H., Li, S.W., Tan, J., Luo, G.S.: Correlations of droplet formation in T-junction microfluidic devices: from squeezing to dripping. Microfluid Nanofluid 5(6), 711–717 (2008). https://doi.org/10.1007/s10404-008-0306-4

Yeom, S., Lee, S.Y.: Size prediction of drops formed by dripping at a micro T-junction in liquid-liquid mixing. Exp. Therm. Fluid Sci 35, 387–394 (2011). https://doi.org/10.1016/j.expthermflusci.2010.10.009

Zhao, C.-X., Middelberg, A.P.J.: Two-phase microfluidic flows. Chem. Eng. Sci 66(7), 1394–1411 (2011). https://doi.org/10.1016/j.ces.2010.08.038

Acknowledgements

This work has been partially supported by the Spanish Ministerio de Economía y Competitividad, Secretaría de Estado de Investigación, Desarrollo e Innovación (Project number MTM2013-46313-R) and the Generalitat de Catalunya (Grant number 2017-SGR-1278).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Arias, S., Montlaur, A. Numerical and Experimental Study of the Squeezing-to-Dripping Transition in a T-Junction. Microgravity Sci. Technol. 32, 687–697 (2020). https://doi.org/10.1007/s12217-020-09794-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12217-020-09794-z