Abstract

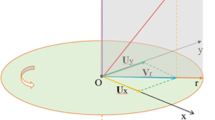

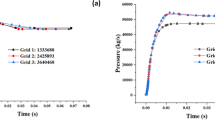

To improve the trapping efficiency of respiratory dust by aerodynamic atomization and to maintain the health and safety of workers, a numerical simulation (droplet fragmentation and particle tracking in a high Mach number flow) and an aerodynamic atomization experiment were adopted on the basis of the existing supersonic aerodynamic atomization nozzles that utilize the Laval nozzle as the core. A new type of this kind of nozzle based on a probe structure was designed and optimized. Both the simulation and experimental results have shown that the probe injection method is more suitable for the progress of supersonic aerodynamic atomization. The new nozzle inherits the characteristics of fast droplet speed, conservation of water and pressure, long-range and slow attenuation. The atomization performance of the new nozzle is better than that of traditional nozzles at the same power, and the new nozzle has a larger atomization angle, smaller atomization granularity, lower noise and a more stable atomization output. For the first time, the process of breaking particles by using supersonic gas in the field of dust removal is truly realized. When the pressure is more than 0.1 MPa, antigravity water absorption can be realized. The dust removal rate can be approximately twice as high as that of the traditional ultrasonic atomization method. Compared with the traditional ultrasonic atomization method (84.75%), the dust isolation efficiency can reach 94.07%. The droplets of ultra-fine size with high-speed produced by the new nozzle will have a strong trapping effect on respiratory dust and will save more energy by the vacuum force siphon than currently used nozzles (the amount of gas saved by the same efficiency is 40% and the amount of water saved is 45%).

Similar content being viewed by others

References

World Health Organization (2016) Ambient air pollution: a global assessment of exposure and burden of disease. World Health Organization. ISBN: 9789241511353. https://apps.who.int/iris/handle/10665/250141

Wen Nie et al (2016) A novel spraying/negative-pressure secondary dust suppression device used in fully mechanized mining face: a case study. Process Saf Environ Prot 103:126–135

Wen Nie et al (2017) The development and testing of a novel external-spraying injection dedusting device for the heading machine in a fully-mechanized excavation face. Process Saf Environ Prot 109:716–731

Zhou Gang, Zhang Qi, Bai Ruonan, Fan Tao, Wang Gang (2017) The diffusion behavior law of respirable dust at fully mechanized caving face in coal mine: CFD numerical simulation and engineering application. Process Saf Environ Prot 106:117–128

Li J, Zhou F, Li S (2017) Experimental study on the dust filtration performance with participation of water mist. Process Saf Environ Prot 109:357–364

Maertens Rebecca M, Gagné Rémi W, Douglas George R, Zhu Jiping, White Paul A (2008) Mutagenic and carcinogenic hazards of settled house dust II: Salmonella Mutagenicity. Environ Sci Technol 42(5):1754–1760

Jang Myoseon, Kamens Richard M (1999) A predictive model for adsorptive gas partitioning of SOCs on fine atmospheric inorganic dust particles. Environ Sci Technol 33(11):1825–1831

Zhao AW, Guo S, Chen SX, Gao S, Li CC (2019) Numerical study on mine dust capture using nano-droplet flow from wet steam condensation. In: Proceedings of the 11th international mine ventilation congress

Wang P, Shi Y, Zhang L, Li Y (2019) Effect of structural parameters on atomization characteristics and dust reduction performance of internal-mixing air-assisted atomizer nozzle. Process Saf Environ Prot 128:316–328

Park Jihoon, Ham Seunghon, Jang Miyeon, Lee Jinho, Kim Sunju, Kim Sungkyoon, Lee Kiyoung, Park Donguk, Kwon Jungtaek, Kim Hyunmi, Kim Pilje, Choi Kyunghee, Yoon Chungsik (2017) Spatial-temporal dispersion of aerosolized nanoparticles during the use of consumer spray products and estimates of inhalation exposure. Environ Sci Technol 51(13):7624–7638

Yang SB, Nie W, Liu ZQ, Peng HT, Cai P (2018) Effects of spraying pressure and installation angle of nozzles on atomization characteristics of external spraying system at a fully-mechanized mining face. Powder Technol. https://doi.org/10.1016/j.powtec.2018.11.042

Jin H, Nie W, Zhang HH, Liu YH, Bao Q, Wang HK (2018) The preparation and characterization of a novel environmentally-friendly coal dust suppressant. J Appl Polym Sci. https://doi.org/10.1002/app.47354

Han Fangwei et al (2016) A new design of foam spray nozzle used for precise dust control in underground coal mines. Int J Min Sci Technol 26(2):241–246

Zhang T, Jing D, Ge S et al (2020) Numerical simulation of the dimensional transformation of atomization in a supersonic aerodynamic atomization dust-removing nozzle based on transonic speed compressible flow. Int J Coal Sci Technol. https://doi.org/10.1007/s40789-020-00314-3

Yang C (2017) Theoretical and Experimental study on spray performance and Dust suppression performance of New Type nozzles. Yanshan University (Doctoral dissertation)

Tang Jiren, Yiyu Lu et al (2015) Optimal design and performance evaluation of a new hydra jet-fracturing nozzle. J China Univ Pet 39:72–78

Cavaliere P (2015) Cold spray coating technology for metallic components repairing. through-life engineering services. Springer International Publishing, Berlin

Zu Hong Biao, Wang ZL (2011) Resonant behaviors of ultra-sonic gas atomization nozzle with zero mass-flux jet actuator. J Shanghai Univ (English Edition) 15(3):166–172

Cheng J (2017) Structure design and numerical simulation of supersonic air atomization nozzle. Anhui University of Science & Technology (Doctoral dissertation)

Tsai SC, Childs P, Luu P, Tsai CS (1995) Ultrasound-modulated twin-fluid jet atomization. IEEE Ultrasonics Symposium. Proceedings. An International Symposium

Deshpande OM, Narappanawar NL (2015) Space advantage provided by de-laval nozzle and bell nozzle over venturi. In: Proceedings of the world congress on engineering. 2015 Vol II WCE 2015, July 1–3, 2015, London, UK

Gopal V, Kolluru R (2014) Numerical study of navier-stokes equations in supersonic flow over a double wedge airfoil using adaptive grids. In: Comsol Eu

Li Qiushi, Lyu Yongzhao et al (2018) Development of a coupled supersonic inlet-fan navier–stokes simulation method. Chin J Aeronaut 31(143):37–46

Sujith RI (2005) An experimental investigation of interaction of sprays with acoustic fields. Exp Fluids 38(5):576–587

Gerasimov AP, Ivanov VP, Krasavin VM, Lakhov VM, Rainchik SV, Semenova OK (2005) The initial equations and the equations for measuring the mass and volume flow rates of a gas. Meas Technol 48(4):374–380

Patel MS, Mane SD, Raman M (2016) Concepts and CFD analysis of De-laval nozzle. Int J Mech Eng Technol (IJMET) 7(5):221–240

Patel Yogini, Patel G, Turunen-Saaresti T (2015) Influence of turbulence modelling on non-equilibrium condensing flows in nozzle and turbine cascade. Int J Heat Mass Transf 88(2015):165–180

Schenk O, Gärtner K (2010) Pardiso

Acknowledgements

The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China (51704146, 51704145, 51274116).

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Erick de Moraes Franklin, Ph.D.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, T., Jing, D., Ge, S. et al. Supersonic antigravity aerodynamic atomization dusting nozzle based on the Laval nozzle and probe jet. J Braz. Soc. Mech. Sci. Eng. 42, 335 (2020). https://doi.org/10.1007/s40430-020-02411-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02411-5