Environmental Assessment of Olive Mill Solid Waste Valorization via Anaerobic Digestion Versus Olive Pomace Oil Extraction

Abstract

:1. Introduction

2. Materials and Methods

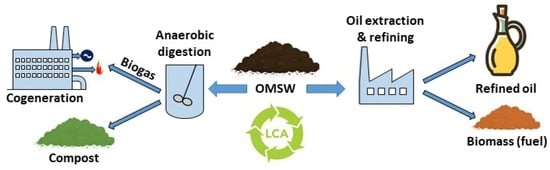

2.1. Goal and Scope of the Study

2.2. Description of the Systems

2.2.1. Anaerobic Digestion (AD)

2.2.2. Olive Pomace Oil Extraction (OPOE)

2.3. Inventory Data

2.3.1. Anaerobic Digestion (AD)

2.3.2. Olive Pomace Oil Extraction (OPOE)

2.3.3. Transport

2.3.4. System Expansion Approach

2.4. Impact Assessment

3. Results

4. Discussion

4.1. Global Warming

4.2. Abiotic Depletion of Elements

4.3. Abiotic Depletion of Fossil Resources and Ozone Layer Depletion

4.4. Human Toxicity

4.5. Ecotoxicity

4.6. Photochemical Oxidation (POP) and Acidification (AP)

4.7. Eutrophication

4.8. Sensitivity Analysis

4.9. Normalization

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Serrano, A.; Fermoso, F.G.; Alonso-Fariñas, B.; Rodríguez-Gutierrez, G.; Fernandez-Bolaños, J.; Borja, R. Olive mill solid waste biorefinery: High-temperature thermal pre-treatment for phenol recovery and biomethanization. J. Clean. Prod. 2017, 148, 314–323. [Google Scholar] [CrossRef] [Green Version]

- García Martín, J.F.; Cuevas Aranda, M.; Feng, C.-H.; Álvarez Mateos, P.; Torres García, M.; Sánchez Villasclaras, S. Energetic valorisation of olive biomass: Olive-tree pruning, olive stones and pomaces. Processes 2020, 8, 511. [Google Scholar] [CrossRef]

- Olimerca. Cunde el Pesimismo Entre Los Orujeros. Available online: https://www.olimerca.com/noticiadet/cunde-el-pesimismo-entre-los-orujeros-/e49e04531bc5c2f12effc6f6c2f30ed8 (accessed on 15 October 2019).

- Rincón, B.; Fermoso, F.G.; Borja, R. Olive Oil Mill Waste Treatment: Improving the Sustainability of the Olive Oil Industry with Anaerobic Digestion Technology. In Olive Oil—Constituents, Quality, Health Properties and Bioconversions; Boskou, D., Ed.; InTech: London, UK, 2012. [Google Scholar]

- Serrano, A.; Fermoso, F.G.; Alonso-Fariñas, B.; Rodríguez-Gutiérrez, G.; López, S.; Fernandez-Bolaños, J.; Borja, R. Performance evaluation of mesophilic semi-continuous anaerobic digestion of high-temperature thermally pre-treated olive mill solid waste. Waste Manag. 2019, 87, 250–257. [Google Scholar] [CrossRef] [PubMed]

- ISO 14040. Environmental Management—Life Cycle Assessment: Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- ISO 14044. Environmental Management—Life Cycle Assessment: Requirements and Guidelines; International Standardization Organization: Geneva, Switzerland, 2006. [Google Scholar]

- Borja, R.; Rincón, B.; Raposo, F. Anaerobic biodegradation of two-phase olive mill solid wastes and liquid effluents: Kinetic studies and process performance. J. Chem. Technol. Biotechnol. 2006, 81, 1450–1462. [Google Scholar] [CrossRef]

- Keith, F.; Tchobanoglous, G. Handbook of Solid Waste Management, 2nd ed.; McGraw-Hill: New York, NY, USA, 2002; ISBN 0071500340. [Google Scholar]

- Hudcová, H.; Vymazal, J.; Rozkošný, M. Present restrictions of sewage sludge application in agriculture within the European Union. Soil Water Res. 2019, 14, 104–120. [Google Scholar] [CrossRef]

- Figueiredo, F.; Marques, P.; Castanheira, É.G.; Kulay, L.; Freire, F. Greenhouse gas assessment of olive oil in Portugal addressing the valorization of olive mill waste. In Proceedings of the Symbiosis International Conference, Athens, Greece, 19–21 June 2014. [Google Scholar]

- Sánchez Moral, P.; Ruiz Méndez, M.V. Production of pomace olive oil. Grasas y Aceites 2006, 57, 47–55. [Google Scholar] [CrossRef]

- Schneider, L.; Finkbeiner, M. Life Cycle Assessment of EU Oilseed Crushing and Vegetable Oil Refining. Tech. Rep. 2013, 2013, 1–59. [Google Scholar]

- Moreno Ruiz, E.; Lévová, T.; Reinhard, J.; Valsasina, L.; Bourgault, G.; Wernet, G. Documentation of Changes Implemented in Ecoinvent Database 3.3; Ecoinvent: Zurich, Switzerland, 2016. [Google Scholar]

- Tampio, E.; Marttinen, S.; Rintala, J. Liquid fertilizer products from anaerobic digestion of food waste: Mass, nutrient and energy balance of four digestate liquid treatment systems. J. Clean. Prod. 2016, 125, 22–32. [Google Scholar] [CrossRef] [Green Version]

- Saer, A.; Lansing, S.; Davitt, N.H.; Graves, R.E. Life cycle assessment of a food waste composting system: Environmental impact hotspots. J. Clean. Prod. 2013, 52, 234–244. [Google Scholar] [CrossRef]

- Cano, R.; Nielfa, A.; Fdz-Polanco, M. Thermal hydrolysis integration in the anaerobic digestion process of different solid wastes: Energy and economic feasibility study. Bioresour. Technol. 2014, 168, 14–22. [Google Scholar] [CrossRef]

- Gonzalez, A. Environmental, Energetic and Economic Fesiability of the Biomethanization of Wastes from the Agri-Food Industry in Extremadura. Ph.D. Thesis, Universidad de Extremadura, Badajoz, Spain, 2014. [Google Scholar]

- Angelidaki, I.; Schmidt, J.E.; Karakashev, D.B. A Sustainable Solution for Pig Manure Treatment: Environmental Compliance with the Integrated Pollution Prevention and Control Directive; CORDIS: Nicosia, Cyprus, 2006. [Google Scholar]

- Potencial Energético de los Subproductos de la Industria Olivarera en Andalucía; Regional Government of Andalusia: Seville, Spain, 2010.

- Intergovernmental Panel on Climate Change. Emissions Factors Database. Available online: https://www.ipcc-nggip.iges.or.jp/EFDB/main.php (accessed on 7 August 2019).

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; Wegener Sleeswijk, A.; Udo De Haes, H.A.; de Bruijn, J.A.; van Duin, R.; Huijbregts, M.A.J. Life Cycle Assessment: An Operational Guide to the ISO Standards; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2001; ISBN 1-4020-0228-9. [Google Scholar]

- Pizzol, M.; Laurent, A.; Sala, S.; Weidema, B.; Verones, F.; Koffler, C. Normalisation and weighting in life cycle assessment: Quo vadis? Int. J. Life Cycle Assess. 2017, 22, 853–866. [Google Scholar] [CrossRef] [Green Version]

- Mercacei. Cunde el Pesimismo Entre Los Orujeros. Available online: https://www.mercacei.com/noticia/47472/actualidad (accessed on 5 July 2019).

- Fernández, J. Los Residuos de las Agroindustrias Como Biocombustibles Sólidos; Vida Rural: Madrid, Spain, 2006; Volume 233, pp. 14–18. [Google Scholar]

- Olivar del Sur. El Olivar, Importante Aliado del Medio Ambiente. Available online: https://olivadelsur.com/es/blog/el-olivar-importante-aliado-del-medio-ambiente-b100.html (accessed on 5 July 2019).

| Total solids (g/L) | 266 ± 4 |

| Volatile solids (g/L) | 250 ± 4 |

| pH | 4.97 ± 0.01 |

| Alkalinity (mg CaCO3/L) | 6559 ± 5 |

| Category | Unit Per Metric Ton of Olive Mill Solid Waste | Anaerobic Digestion (AD) | Olive Pomace Oil Extraction (OPOE-A) 3 | Olive Pomace Oil Extraction (OPOE-B) 4 |

|---|---|---|---|---|

| Electricity | kWh | −215.06 1 | 2.42 | 2.42 |

| Heat | MJ | −850.97 2 | 0.06 | 0.06 |

| Diesel | kg | na | 1.07 | 1.07 |

| Natural gas | m3 | na | 61.9 | na |

| Compost | kg | 221.03 | na | na |

| Refined olive pomace oil | kg | na | 22.17 | 22.17 |

| Extracted olive pomace | kg | na | 224.39 | 82.46 |

| Water | kg | 157.75 | 3652 | 3652 |

| Technical hexane | kg | na | 0.03 | 0.03 |

| NaOH solution | kg | na | 0.11 | 0.11 |

| Emissions to air | ||||

| CO2 (fossil) | kg | na | 143.07 | 3.37 |

| CH4 | kg | 1.15 | 0.91 | 0.91 |

| N2O | kg | 0.05 | 0.05 | 0.05 |

| NH3 | kg | 0.25 | na | na |

| Technical hexane | na | 0.02 | 0.02 | |

| Olive mill solid waste transportation | tkm | na | 100.00 | 100.00 |

| Wastewater to treatment | m3 | na | 3.10 | 3.10 |

| Ashes to landfarming | kg | na | na | 3.78 |

| Anaerobic digestion | ||

| Outcomes | Credits for avoided products | Equivalence ratio |

| Electricity | Medium voltage-Spanish mix | 1:1 (kwh) |

| Heat | Industrial heat from natural gas | 1:1 (MJ) |

| Compost | Peat 1 | 1:1 (kg) 1 |

| Olive pomace oil extraction | ||

| Outcomes | Credits for avoided products | Equivalence ratio |

| Refined olive pomace oil | Refined vegetable oil | 1:1 (kg) |

| Extracted olive pomace | Natural gas | 1:1 (MJ) 2 |

| Impact Category | Anaerobic Digestion (AD) | Olive Pomace Oil Extraction (OMOE-A) | Olive Pomace Oil Extraction (OMOE-B) |

|---|---|---|---|

| ADe | −1.40 × 10−13 | −3.89 × 10−13 | −3.89 × 10−13 |

| ADf | −7.86 × 10−11 | −4.53 × 10−11 | −4.53 × 10−11 |

| GWP | −2.76 × 10−11 | 1.13 × 10−11 | −1.65 × 10−11 |

| ODP | −2.71 × 10−13 | −4.19 × 10−14 | −4.19 × 10−14 |

| HTP | −2.92 × 10−12 | −1.33 × 10−12 | −9.27 × 10−13 |

| FWEP | −2.79 × 10−11 | −9.66 × 10−11 | −9.43 × 10−11 |

| MWEP | −8.55 × 10−10 | −1.31 × 10−10 | −1.26 × 10−10 |

| TEP | −2.22 × 10−12 | −2.36 × 10−10 | −2.31 × 10−10 |

| POP | −2.71 × 10−12 | −6.30 × 10−12 | −6.30 × 10−12 |

| AP | −9.36 × 10−12 | −1.50 × 10−11 | −1.50 × 10−11 |

| EP | −1.17 × 10−11 | −2.07 × 10−11 | −1.21 × 10−11 |

| Single score 1 | −1.02 × 10−9 | −5.41 × 10−10 | −5.48 × 10−10 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alonso-Fariñas, B.; Oliva, A.; Rodríguez-Galán, M.; Esposito, G.; García-Martín, J.F.; Rodríguez-Gutiérrez, G.; Serrano, A.; Fermoso, F.G. Environmental Assessment of Olive Mill Solid Waste Valorization via Anaerobic Digestion Versus Olive Pomace Oil Extraction. Processes 2020, 8, 626. https://doi.org/10.3390/pr8050626

Alonso-Fariñas B, Oliva A, Rodríguez-Galán M, Esposito G, García-Martín JF, Rodríguez-Gutiérrez G, Serrano A, Fermoso FG. Environmental Assessment of Olive Mill Solid Waste Valorization via Anaerobic Digestion Versus Olive Pomace Oil Extraction. Processes. 2020; 8(5):626. https://doi.org/10.3390/pr8050626

Chicago/Turabian StyleAlonso-Fariñas, Bernabé, Armando Oliva, Mónica Rodríguez-Galán, Giovanni Esposito, Juan Francisco García-Martín, Guillermo Rodríguez-Gutiérrez, Antonio Serrano, and Fernando G. Fermoso. 2020. "Environmental Assessment of Olive Mill Solid Waste Valorization via Anaerobic Digestion Versus Olive Pomace Oil Extraction" Processes 8, no. 5: 626. https://doi.org/10.3390/pr8050626