Abstract

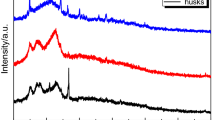

The corn crop biomass (CB) is widely used as a feedstock for biochemicals such as lactic acid, succinic acid, citric acid, xanthan gum, and biofuels likely bioethanol, butanol, and biogas. Since CB provides a resistive structure for enzymatic and microbial attack, ultrasonic treatment can assist to break the recalcitrance structure. Several techniques such as imaging (atomic force microscopy—AFM; scanning electron microscopy—SEM), spectroscopy (energy-dispersive X-ray spectroscopy—EDX; Fourier transform infrared spectroscopy—FTIR; Raman spectroscopy; X-ray diffraction—XRD), and thermal (TGA) were studied to characterize the ultrasonicated CB. A detailed analysis of different techniques on their potential benefits will assist the researchers to select a suitable technique to optimize the ultrasonication for various applications. The basic mechanisms behind ultrasonication, benefits, downsides, practical considerations, and factors that should be deliberated in the future studies are discussed. Sonication enhanced the hemicellulose and cellulose yield, saccharification rate, and delignification of CB. AFM, EDX, FTIR, Raman spectroscopy, SEM, TGA, and XRD described the variations in topographical features, elemental composition, molecular structure, microstructure, thermal steadiness, and degree of crystallinity, respectively, of the ultrasonicated CB. The quantitative crystallinity of CB can be analyzed through XRD and Raman spectroscopy, whereas the qualitative crystallinity and molecular structural comparisons are studied using FTIR. Imaging techniques can provide important aspects such as lignin relocalization and cell wall delamination. Integrating EDX with SEM is beneficial to determine the elemental percentage composition altered in CB due to ultrasonication.

Graphical abstract

Similar content being viewed by others

Abbreviations

- AFM:

-

atomic force microscopy

- CB:

-

corn biomass

- CC:

-

corn cob

- CCSAA:

-

corn cob soaked in aqueous ammonia

- CCUSAA:

-

corn cob pretreated by ultrasound-assisted soaking in aqueous ammonia

- CGM:

-

corn gluten meal

- CHFs:

-

corn husk fibers

- CrI:

-

degree of crystallinity

- CS:

-

corn stover

- CSFs:

-

corn straw fibers

- DDGS:

-

dried distiller’s grains with solubles

- DSA:

-

dilute sulfuric acid

- EDX:

-

energy-dispersive X-ray spectroscopy

- FTIR:

-

Fourier transform infrared spectroscopy

- RMS:

-

root mean square

- SEM:

-

scanning electron microscopy

- SP:

-

sodium percarbonate

- TGA:

-

thermogravimetric analysis

- USP:

-

ultrasonic processing

- UVA:

-

ultrasonic vibration-assisted

- XRD:

-

X-ray diffraction

References

Bessou C, Ferchaud F, Gabrielle B et al (2011) Biofuels, greenhouse gases and climate change. A review. Sustain Agric 2:365–468

Nakashima K, Ebi Y, Kubo M et al (2016) Pretreatment combining ultrasound and sodium percarbonate under mild conditions for efficient degradation of corn stover. Ultrason Sonochem 29:455–460. https://doi.org/10.1016/j.ultsonch.2015.10.017

Gáspár M, Juhász T, Szengyel Z, Réczey K (2005) Fractionation and utilisation of corn fibre carbohydrates. Process Biochem 40:1183–1188. https://doi.org/10.1016/j.procbio.2004.04.004

Garrote G, Domínguez H, Parajó JC (2002) Autohydrolysis of corncob: study of non-isothermal operation for xylooligosaccharide production. J Food Eng 52:211–218. https://doi.org/10.1016/S0260-8774(01)00108-X

Sari NH, Wardana ING, Irawan YS, Siswanto E (2017) The effect of sodium hydroxide on chemical and mechanical properties of corn husk fiber. Orient J Chem 33:3037–3042. https://doi.org/10.13005/ojc/330642

Shukla R, Cheryan M (2001) Zein: The industrial protein from corn. Ind Crop Prod 13:171–192. https://doi.org/10.1016/S0926-6690(00)00064-9

Rose DJ, Inglett GE, Liu SX (2010) Utilisation of corn (Zea mays) bran and corn fiber in the production of food components. J Sci Food Agric 90:915–924. https://doi.org/10.1002/jsfa.3915

Menon V, Rao M (2012) Trends in bioconversion of lignocellulose: biofuels, platform chemicals & biorefinery concept. Prog Energy Combust Sci 38:522–550. https://doi.org/10.1016/j.pecs.2012.02.002

Subhedar PB, Gogate PR (2013) Intensification of enzymatic hydrolysis of lignocellulose using ultrasound for efficient bioethanol production: a review. Ind Eng Chem Res 52:11816–11828. https://doi.org/10.1021/ie401286z

Wang P, Liu C, Chang J et al (2019) Effect of physicochemical pretreatments plus enzymatic hydrolysis on the composition and morphologic structure of corn straw. Renew Energy 138:502–508. https://doi.org/10.1016/j.renene.2019.01.118

Karimi K (2014) Current and future ABE processes. Biofuel Res J 4:77

Salehian P, Karimi K, Zilouei H, Jeihanipour A (2013) Improvement of biogas production from pine wood by alkali pretreatment. Fuel 106:484–489. https://doi.org/10.1016/j.fuel.2012.12.092

Karimi K, Shafiei M, Kumar R (2013) Progress in physical and chemical pretreatment of lignocellulosic biomass. In: Gupta, VK, Tuohy, M G (Eds.), Biofuel Technologies. Springer, Berlin, Heidelberg, pp. 53–96.

Kumar R, Wyman CE (2013) Physical and chemical features of pretreated biomass that influence macro-/micro-accessibility and biological processing. In: Wyman CE (ed) Aqueous pretreatment of plant biomass for biological and chemical conversion to fuels and chemicals, 1st edn. Wiley, New York, pp 281–310

Tobergte DR, Curtis S (2013) Ultrasound technologies for food bioprocessing. Springer, New York

Bussemaker MJ, Zhang D (2013) Effect of ultrasound on lignocellulosic biomass as a pretreatment for biorefinery and biofuel applications. Ind Eng Chem Res 52:3563–3580. https://doi.org/10.1021/ie3022785

Kumar AK, Sharma S (2017) Recent updates on different methods of pretreatment of lignocellulosic feedstocks: a review. Bioresour Bioprocess 4:7. https://doi.org/10.1186/s40643-017-0137-9

Kunaver M, Jasiukaityte E, Čuk N (2012) Ultrasonically assisted liquefaction of lignocellulosic materials. Bioresour Technol 103:360–366. https://doi.org/10.1016/j.biortech.2011.09.051

Huezo L, Shah A, Michel FC (2019) Effects of ultrasound on fermentation of glucose to ethanol by saccharomyces cerevisiae. Fermentation 5:1–14. https://doi.org/10.3390/fermentation5010016

Gogate PR, Sutkar VS, Pandit AB (2011) Sonochemical reactors: Important design and scale up considerations with a special emphasis on heterogeneous systems. Chem Eng J 166:1066–1082. https://doi.org/10.1016/j.cej.2010.11.069

Nitayavardhana S, Shrestha P, Rasmussen ML et al (2010) Ultrasound improved ethanol fermentation from cassava chips in cassava-based ethanol plants. Bioresour Technol 101:2741–2747. https://doi.org/10.1016/j.biortech.2009.10.075

Ebringerová A, Hromádková Z (2002) Effect of ultrasound on the extractibility of corn bran hemicelluloses. Ultrason Sonochem 9:225–229. https://doi.org/10.1016/S1350-4177(01)00124-9

Zhang YQ, Fu E, Liang J (2008) Effect of ultrasonic waves on the saccharification processes of lignocellulose. Chem Eng Technol 31:1510–1515. https://doi.org/10.1002/ceat.200700407

Jin J, Ma H, Wang K et al (2015) Effects of multi-frequency power ultrasound on the enzymolysis and structural characteristics of corn gluten meal. Ultrason Sonochem 24:55–64. https://doi.org/10.1016/j.ultsonch.2014.12.013

Du R, Su R, Qi W, He Z (2018) Enhanced enzymatic hydrolysis of corncob by ultrasound-assisted soaking in aqueous ammonia pretreatment. 3. Biotech 8:166. https://doi.org/10.1007/s13205-018-1186-2

Montalbo-Lomboy M, Khanal SK, van Leeuwen J et al (2010) Ultrasonic pretreatment of corn slurry for saccharification: a comparison of batch and continuous systems. Ultrason Sonochem 17:939–946. https://doi.org/10.1016/j.ultsonch.2010.01.013

Dong C, Chen J (2019) Optimization of process parameters for anaerobic fermentation of corn stalk based on least squares support vector machine. Bioresour Technol 271:174–181. https://doi.org/10.1016/j.biortech.2018.09.085

Nikolić S, Mojović L, Rakin M et al (2010) Ultrasound-assisted production of bioethanol by simultaneous saccharification and fermentation of corn meal. Food Chem 122:216–222. https://doi.org/10.1016/j.foodchem.2010.02.063

Yachmenev V, Condon B, Klasson T, Lambert A (2009) Acceleration of the enzymatic hydrolysis of corn stover and sugar cane bagasse celluloses by low intensity uniform ultrasound. J Biobased Mater Bioenergy 3:25–31. https://doi.org/10.1166/jbmb.2009.1002

Hroma Z, Ebringerova A (1999) Study of the classical and ultrasound-assisted extraction of the corn cob xylan. Ind Crop Prod 9:101–109

Khanal SK, Montalbo M, Van Leeuwen JH et al (2007) Ultrasound enhanced glucose release from corn in ethanol plants. Biotechnol Bioeng 98:978–985. https://doi.org/10.1002/bit

Montalbo-lomboy M, Johnson L, Kumar S et al (2010) Sonication of sugary-2 corn: a potential pretreatment to enhance sugar release sugar release. Bioresour Technol 101:351–358. https://doi.org/10.1016/j.biortech.2009.07.075

Xu QQ, Zhao MJ, Yu ZZ et al (2017) Enhancing enzymatic hydrolysis of corn cob, corn stover and sorghum stalk by dilute aqueous ammonia combined with ultrasonic pretreatment. Ind Crop Prod 109:220–226. https://doi.org/10.1016/j.indcrop.2017.08.038

Yin J, Hao L, Yu W et al (2014) Enzymatic hydrolysis enhancement of corn lignocellulose by supercritical CO2 combined with ultrasound pretreatment. Chin J Catal 35:763–769. https://doi.org/10.1016/s1872-2067(14)60040-1

Pérez-Rodríguez N, García-Bernet D, Domínguez JM (2016) Effects of enzymatic hydrolysis and ultrasounds pretreatments on corn cob and vine trimming shoots for biogas production. Bioresour Technol 221:130–138. https://doi.org/10.1016/j.biortech.2016.09.013

García A, Alriols MG, Llano-Ponte R, Labidi J (2011) Ultrasound-assisted fractionation of the lignocellulosic material. Bioresour Technol 102:6326–6330. https://doi.org/10.1016/j.biortech.2011.02.045

Donohoe BS, Vinzant TB, Elander RT et al (2011) Surface and ultrastructural characterization of raw and pretreated switchgrass. Bioresour Technol 102:11097–11104. https://doi.org/10.1016/j.biortech.2011.03.092

Yarbrough JM, Himmel ME, Ding SY (2009) Plant cell wall characterization using scanning probe microscopy techniques. Biotechnol Biofuels 2:1–11. https://doi.org/10.1186/1754-6834-2-17

Terinte N, Ibbett R, Schuster KC (2011) Overview on native cellulose & microcrystalline cellulose I structures studies by XRD (WAXD): comparison between measurement techniques. Lenzinger Berichte 89:118–131

Banerjee S, Yang R, Courchene CE, Conners TE (2009) Scanning electron microscopy measurements of the surface roughness of paper. Ind Eng Chem Res 48:4322–4325. https://doi.org/10.1021/ie900029v

Ciesielski A, Samorì P (2014) Graphene via sonication assisted liquid-phase exfoliation. Chem Soc Rev 43:381–398. https://doi.org/10.1039/c3cs60217f

Ostovareh S, Karimi K, Zamani A (2015) Efficient conversion of sweet sorghum stalks to biogas and ethanol using organosolv pretreatment. Ind Crop Prod 66:170–177. https://doi.org/10.1016/j.indcrop.2014.12.023

Zhang Q, Zhang P, Pei Z, Wang D (2017) Investigation on characteristics of corn stover and sorghum stalk processed by ultrasonic vibration-assisted pelleting. Renew Energy 101:1075–1086. https://doi.org/10.1016/j.renene.2016.09.071

Maepa CE, Jayaramudu J, Okonkwo JO et al (2015) Extraction and characterization of natural cellulose fibers from maize tassel. Int J Polym Anal Charact 20:99–109. https://doi.org/10.1080/1023666X.2014.961118

Fan M, Dai D, Huang B (2012) Fourier transform infrared spectroscopy for natural fibres. Fourier Transform - Materials Analysis 3:45–68. https://doi.org/10.5772/35482

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the x-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Ju X, Bowden M, Brown EE, Zhang X (2015) An improved X-ray diffraction method for cellulose crystallinity measurement. Carbohydr Polym 123:476–481. https://doi.org/10.1016/j.carbpol.2014.12.071

French AD, Santiago Cintrón M (2013) Cellulose polymorphy, crystallite size, and the segal crystallinity index. Cellulose 20:583–588. https://doi.org/10.1007/s10570-012-9833-y

Krishnaiah P, Ratnam CT, Manickam S (2017) Enhancements in crystallinity, thermal stability, tensile modulus and strength of sisal fibres and their PP composites induced by the synergistic effects of alkali and high intensity ultrasound (HIU) treatments. Ultrason Sonochem 34:729–742. https://doi.org/10.1016/j.ultsonch.2016.07.008

Karp EM, Resch MG, Donohoe BS et al (2015) Alkaline pretreatment of switchgrass. ACS Sustain Chem Eng 3:1479–1491. https://doi.org/10.1021/acssuschemeng.5b00201

Mouille G, Robin S, Lecomte M et al (2003) Classification and identification of Arabidopsis cell wall mutants using Fourier-transform infrared (FT-IR) microspectroscopy. Plant J 35:393–404. https://doi.org/10.1046/j.1365-313X.2003.01807.x

Zhou C, Hu J, Yu X et al (2017) Heat and/or ultrasound pretreatments motivated enzymolysis of corn gluten meal: hydrolysis kinetics and protein structure. LWT Food Sci Technol 77:488–496. https://doi.org/10.1016/j.lwt.2016.06.048

Tian S, Wang Z, Fan Z, Zuo L (2012) Comparison of ultrasonic and CO2 laser pretreatment methods on enzyme digestibility of corn stover. Int J Mol Sci 13:4141–4152. https://doi.org/10.3390/ijms13044141

Ebringerová A, Hromádková Z (1997) The effect of ultrasound on the structure and properties of the water-soluble corn hull heteroxylan. Ultrason Sonochem 4(4):305–309. https://doi.org/10.1016/S1350-4177(97)00037-0

Qu W, Liu J, Xue Y et al (2018) Potential of producing carbon fiber from biorefinery corn stover lignin with high ash content. J Appl Polym Sci 135:1–11. https://doi.org/10.1002/app.45736

Agarwal UP, Reiner RS, Ralph SA (2010) Cellulose I crystallinity determination using FT–Raman spectroscopy: univariate and multivariate methods. Cellulose 17:721–733. https://doi.org/10.1007/s10570-010-9420-z

Jin J, Ma H, Wang B, Yagoub AEGA, Wang K, He R, Zhou C (2016) Effects and mechanism of dual-frequency power ultrasound on the molecular weight distribution of corn gluten meal hydrolysates. Ultrason Sonochem 30:44–51. https://doi.org/10.1016/j.ultsonch.2015.11.021

Kambli ND, Samanta KK, Basak S et al (2018) Characterization of the corn husk fibre and improvement in its thermal stability by banana pseudostem sap. Cellulose 25:5241–5257. https://doi.org/10.1007/s10570-018-1931-z

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. Laboratory Analytical Procedure, NREL/TP-510-42618.

Ciolacu D, Ciolacu F, Popa VI (2011) Amorphous cellulose–structure and characterization. Cellul Chem Technol 45:13–21

Zhang M, Chen G, Kumar R, Xu B (2013) Mapping out the structural changes of natural and pretreated plant cell wall surfaces by atomic force microscopy single molecular recognition imaging. Biotechnol Biofuels 6:1–11. https://doi.org/10.1186/1754-6834-6-147

Isogai A, Atalla AH (1991) Amorphous celluloses stable in aqueous media. Regeneration from SO2-amine solvent systems. J Polym Sci Part A: Polym. Chem 29:113–119. https://doi.org/10.1002/pola.1991.080290113

Zang D, Zhang M, Liu F, Wang C (2016) Superhydrophobic/superoleophilic corn straw fibers as effective oil sorbents for the recovery of spilled oil. J Chem Technol Biotechnol 91:2449–2456. https://doi.org/10.1002/jctb.4834

Li J, Qiang D, Zhang M et al (2015) Joint action of ultrasonic and Fe3+ to improve selectivity of acid hydrolysis for microcrystalline cellulose. Carbohydr Polym 129:44–49. https://doi.org/10.1016/j.carbpol.2015.04.034

Acknowledgements

This work was supported by BioFuelNet Canada; Ontario Ministry of Agriculture, Food and Rural Affairs, Guelph Ontario, IGPC Ethanol Inc., Aylmer, Ontario, Canada.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharma, S., Pradhan, R., Manickavasagan, A. et al. Characterization of ultrasonic-treated corn crop biomass using imaging, spectral and thermal techniques: a review. Biomass Conv. Bioref. 12, 1393–1408 (2022). https://doi.org/10.1007/s13399-020-00748-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00748-4