Abstract

Background:

Three-dimensional (3D) printing using hydrogel has made great strides when it comes to mimicking 3D artificial tissue in the medical field. However, most structures do not mimic the dynamic movement of the tissues. Without imitating dynamic movements, there are limitations on the extent to which the proper implementation of the tissue's own functions can be achieved.

Method:

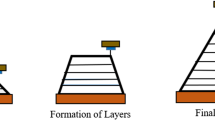

In this study, we intend to present an approach to solving this problem using hydroxybutyl methacrylated chitosan (HBC-MA), a photo-crosslinkable/temperature reversible chitosan polymer. In addition, stereolithography-3D (SLA-3D) printing technology was used, which is more likely to mimic the complex microstructure. As a control, a 3D structure made with pristine poly(ethylene glycol) dimethacrylate (PEG-DMA) was created, and a 4D structure was prepared by adding HBC-MA to poly(ethylene glycol) dimethacrylate (PEG-DMAP) resin.

Results:

HBC-MA caused the expansion of water into the polymer matrix at low temperature, and the 4D structure resulted in expansion of the polymer volume, generating dynamic movement due to the expansion of water. Conversely, as the temperature rose, deswelling occurred, followed by a decrease in the volume, showing a shape memory property of returning to the existing structure. Morphological, swelling, and mechanical analysis further confirmed the principle of dynamic movement. In addition, parameters were provided through calculation of the bending ratio angle (θ).

Conclusion:

Through this, it is suggested that HBC-MA can be applied as a core polymer for SLA-4D printing, and has high potential for realizing the dynamic movement of tissue.

Similar content being viewed by others

References

Morris VB, Nimbalkar S, Younesi M, McClellan P, Akkus O. Mechanical properties, cytocompatibility and manufacturability of chitosan: PEGDA hybrid-gel scaffolds by stereolithography. Ann Biomed Eng. 2017;45:286–96.

Jung BK, Kim JY, Kim YS, Roh TS, Seo A, Park KH, et al. Ideal scaffold design for total ear reconstruction using a three-dimensional printing technique. J Biomed Mater Res B Appl Biomater. 2019;107:1295–303.

Goyanes A, Det-Amornrat U, Wang J, Basit AW, Gaisford S. 3D scanning and 3D printing as innovative technologies for fabricating personalized topical drug delivery systems. J Control Release. 2016;234:41–8.

Nuseir A, Hatamleh MM, Alnazzawi A, Al-Rabab'ah M, Kamel B, Jaradat E. Direct 3D printing of flexible nasal prosthesis: optimized digital workflow from scan to fit. J Prosthodont. 2019;28:10–4.

Fortney SM, Nadel ER, Wenger CB, Bove JR. Effect of blood volume on sweating rate and body fluids in exercising humans. J Appl Physiol Respir Environ Exerc Physiol. 1981;51:1594–600.

Wendt D, van Loon LJC, Lichtenbelt WDM. Thermoregulation during exercise in the heat. Sports Med. 2007;37:669–82.

Costa M, Furness JB. The peristaltic reflex: an analysis of the nerve pathways and their pharmacology. Naunyn Schmiedebergs Arch Pharmacol. 1976;294:47–60.

Kunze WA, Furness JB. The enteric nervous system and regulation of intestinal motility. Annu Rev Physiol. 1999;61:117–42.

Xiao Y, Ahadian S, Radisic M. Biochemical and biophysical cues in matrix design for chronic and diabetic wound treatment. Tissue Eng Part B Rev. 2016;23:9–26.

Momeni F, Hassani.N SMM, Liu X, Ni J. A review of 4D printing. Mater Des. 2017;122:42–79.

Wu GH, Hsu SH. Review: polymeric-based 3D printing for tissue engineering. J Med Biol Eng. 2015;35:285–92.

Ma X, Qu X, Zhu W, Li YS, Yuan S, Zhang H, et al. Deterministically patterned biomimetic human iPSC-derived hepatic model via rapid 3D bioprinting. Proc Natl Acad Sci U S A. 2016;113:2206–11.

Ge Q, Dunn CK, Qi HJ, Dunn ML. Active origami by 4D printing. Smart Mater Struct. 2014;23:094007.

Kuksenok O, Balazs AC. Stimuli-responsive behavior of composites integrating thermo-responsive gels with photo-responsive fibers. Mater Horiz. 2016;3:53–62.

Bakarich SE, Gorkin R 3rd, in het Panhuis M, Spinks GM. 4D printing with mechanically robust, thermally actuating hydrogels. Macromol Rapid Commun. 2015;36:1211–7.

Tsukamoto Y, Akagi T, Shima F, Akashi M. Fabrication of orientation-controlled 3D tissues using a layer-by-layer technique and 3D printed a thermoresponsive gel frame. Tissue Eng Part C Methods. 2017;23:357–66.

Yoon HJ, Shin SR, Cha JM, Lee SH, Kim JH, Do JT, et al. Cold water fish gelatin methacryloyl hydrogel for tissue engineering application. PLoS One. 2016;11:e0163902.

Gladman AS, Matsumoto EA, Nuzzo RG, Mahadevan L, Lewis JA. Biomimetic 4D printing. Nat Mater. 2016;15:413–8.

Shih H, Fraser AK, Lin CC. Interfacial thiol-ene photoclick reactions for forming multilayer hydrogels. ACS Appl Mater Interfaces. 2013;5:1673–80.

Nichol JW, Koshy ST, Bae H, Hwang CM, Yamanlar S, Khademhosseini A. Cell-laden microengineered gelatin methacrylate hydrogels. Biomaterials. 2010;31:5536–44.

Zhang XZ, Chu CC. Preparation of thermosensitive PNIPAAm hydrogels with superfast response. Chem Commun (Camb). 2004;3:350–1.

Zhang XZ, Xu XD, Cheng SX, Zhuo RX. Strategies to improve the response rate of thermosensitive PNIPAAm hydrogels. Soft Matter. 2008;4:385–91.

Yuan M, Bi B, Huang J, Zhuo R, Jiang X. Thermosensitive and photocrosslinkable hydroxypropyl chitin-based hydrogels for biomedical applications. Carbohydr Polym. 2018;192:10–8.

Do AV, Worthington KS, Tucker BA, Salem AK. Controlled drug delivery from 3D printed two-photon polymerized poly(ethylene glycol) dimethacrylate devices. Int J Pharm. 2018;552:217–24.

Kadry H, Wadnap S, Xu C, Ahsan F. Digital light processing (DLP) 3D-printing technology and photoreactive polymers in fabrication of modified-release tablets. Eur J Pharm Sci. 2019;135:60–7.

Naficy S, Brown HR, Razal JM, Spinks GM, Whitten PG. Progress toward robust polymer hydrogels. Aust J Chem. 2011;64:1007–25.

Acknowledgements

This paper was funded by the National Research Foundation of Korea (NRF) grant funded by the Korean Government (MSIT) (NRF-2015R1A5A1009701, NRF-2018R1D1A1B05047274, and NRF-2016M3A9B6946859), and was supported by Konkuk University Researcher Fund in 2018.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no financial or commercial conflicts of interest that are directly related to the content of this article.

Ethical statement

All the authors declare that there are no ethical issues for humans and animals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary file2 (MP4 18064 kb)

Supplementary file3 (MP4 18778 kb)

Rights and permissions

About this article

Cite this article

Seo, J.W., Shin, S.R., Park, Y.J. et al. Hydrogel Production Platform with Dynamic Movement Using Photo-Crosslinkable/Temperature Reversible Chitosan Polymer and Stereolithography 4D Printing Technology. Tissue Eng Regen Med 17, 423–431 (2020). https://doi.org/10.1007/s13770-020-00264-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13770-020-00264-6