Abstract

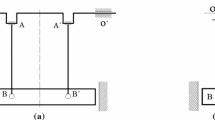

Motor cores demand precision for the purpose of product shape refinement and to increase the performance. To enhance the lamination method and the efficiency of the product, the material thickness is becoming thinner. In addition, press machines require a mass-production system with high precision. In an experiment, the effects of the displacement and fluctuations of the bottom dead center on a high-speed press were investigated. The experiment was carried out by sequentially increasing the press speed from 50 to 130 and 270 spm. The bottom dead-center displacement levels of the press were 0 mm at 50 spm and 0.05 mm at 130 spm. At the speed 270 spm, the bottom dead-center displacement increased from 0.1 to 0.15 mm. As a result of analyzing the types of bottom dead-center fluctuation, a change from 61 to 273 μm was considered. The required height to guarantee the quality of the motor core embossing outcome is 0.05 mm, which can be realized by fine adjustments of the mold at a fluctuation level of 61 μm. The embossing process leads to piercing at the fluctuations of 85–89 µm and 273 µm, requiring a total press overhaul or partial repair. In this paper, as the press speed increases, the bottom dead-center displacement increases and the bottom dead-center fluctuation affects the forming results of the embossing process.

Similar content being viewed by others

References

Kim HK, Jung CJ, Cho C (2014) Dynamic-elastic deformation analysis for the precise design of a high-speed press machine. Trans Korean Soc Mech Eng A 38(1):79–88

Kim JH (2014) A numerical study of the effects of the material properties on the surface deflection in a rectangular embossing process. Seoul National University, Seoul

Kim S-S, Kim Y-J, Goo B-B, Kim W-S, Lee C-K (2016) A study of the embossing height displacement of high-speed press bottom point accordance. J Korean Soc Die Mold Eng 10(2):29–33

Kim S-S (2016) A structural study of mold EMBO equipment to minimize the influence on the bottom dead-center displacement of a precision high-speed press. J Korean Soc Die Mold Eng 10(3):46–50

Kim S-S (2019) A study on the variation analysis of high-speed press bottom displacement and characteristics of motor core molds and products. Department of Metal Mold Design Engineering, Kongju National University

Lee S-D (2002) A study of the motion for offset link press. Department of Mechanical Engineering at Ajou University

Sihong Z, Junfang L, Huiyun W (2006) Finite element analysis of high-speed press. In: CAIDCD 06. 7th international conference of computer-aided industrial design and conceptual design, 2006, 2006 Nov, pp 1–5

Jia F, Xu F (2014) Dynamic analysis of closed high-speed precision press: modeling, simulation and experiments. Proc Inst Mech Eng J Mech Eng Sci 228(13):2383–2401

Zheng X, Yao JL, Wang JL (2012) Research on vibration control of high-speed press frame structure. Appl Mech Mater 226(228):308–311

Zheng X, Wang JL, Yao JL (2012) Bottom dead-center repeat precision of high-speed press measurement. Appl Mech Mater 249(250):31–35

Zheng E, Jia F, Zhu S (2014) Thermal modelling and characteristic analysis of a high-speed press system. Int J Mach Tools Manuf 85:87–99

Hong C, Ruiming F, Xiaoling Z (2004) Optimal design of the speed-changeable sheet-fed mechanism in a high-speed press. Chin J Mech Eng 17:185–188

Chen Y, Sun Y, Yang D (2017) Investigations of the dynamic characteristics of a planar slider-crank mechanism for a high-speed press system that considers joint clearance. J Mech Sci Technol 31(1):75–85

Li C-H, Tso P-L (2006) A study of dynamic balancing for high-speed presses. JSME Int J Ser C Mech Syst Mach Elements Manuf 49(3):657–662

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Lincoln Cardoso Brandao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lee, CK., Kim, SS., Lee, M. et al. A study of the influence of high-speed press bottom dead-center displacement and fluctuation on motor core products. J Braz. Soc. Mech. Sci. Eng. 42, 321 (2020). https://doi.org/10.1007/s40430-020-02417-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02417-z