Abstract

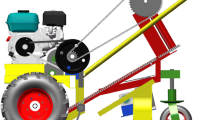

The new technology of filming in autumn and planting directly through the plastic film in spring is an effective water-saving method and drought-resistance commercial potato production. However, filming first and then planting is not compatible with the working of known potato mulching planters. In order to realize the hill-drop under plastic-film in potato seeding, a double crank multi-rod mechanism has been designed and a prototype built. Using computer-aided design software, the effect of several kinematic parameters upon the motion of the planter dibber has been systematically investigated. A mechanism with optimized parameters has then been built and tested in a dry farming area of the Loessal Plateau of Northwest China. Results showed that the qualified rate of sowing depth under plastic-film was 92%, the rate of hole dislocation was 5%, the qualified rate of hole distance was 88% and the mechanical-damage degree of plastic-film lighting surface was 52.1 mm/m2. The proposed planter meets all the agronomic requirements of hill-drop on plastic-film potato planting, and has the potential to perform well in other geographic areas, where comparable farming conditions exist.

Resumen

La nueva tecnología de colocar el plástico en el otoño y de plantar directamente a través del plástico en primavera, es un método efectivo de ahorrar agua y de producción de papa comercial resistente a la sequía. No obstante, la colocación del plástico primero y de sembrar después, es incompatible con el trabajo de las sembradoras con acolchado de la papa conocidas. A fin de comprender el surcado bajo la cubierta de plástico en la siembra de papa, se ha diseñado un mecanismo de doble manivela de biela múltiple construyéndose un prototipo. Mediante el uso de un programa diseñado en computadora, se ha investigado sistemáticamente el efecto de varios parámetros cinemáticos sobre el movimiento de la sembradora. Se construyó entonces un mecanismo con parámetros optimizados y se ha probado en un área de siembra seca de la planicie Loessal nor-occidental de China. Los resultados mostraron que el nivel satisfactorio de la profundidad de siembra bajo la película de plástico era del 92%, el nivel de desubicación del hoyo fue del 5%, el nivel calificado de distancia entre los hoyos fue 88%, y el grado de daño mecánico de la superficie reflejante de la película de plástico fue de 52.1 mm/m2. La sembradora propuesta reúne todos los requerimientos agronómicos del surcado en la siembra de la papa con plástico, y tiene el potencial de desempeñarse bien en otras áreas geográficas, donde existan condiciones de cultivo compatibles.

Similar content being viewed by others

References

Chen, J.B., Z.T. Zhang, B.W. Hao, H.Y. Liu, and W.W. Duan. 2013. Effect of mulching soil on growth of potato mulched with plastic-film in dry land. Bulletin of Agricultural Science and Technology 4: 55–57.

Dai, H.L., S.H. Qin, J.L. Zhang, D. Wang, C.L. Wang, and L. Chen. 2012. Effects of plastic film and ridge-furrow cropping patterns on growth and yield of potato in semiarid areas. Agricultural Research in the Arid Areas 30 (5): 56–60.

Duke, M., B. McGuinness, and R. Kunnemeyer. 2016. Development of mechatronic dibbling machine for improving the quality of forestry seedlings. Acta Technica Corviniensis 9 (3): 51–56.

Fu, Y.C., S.J. Gu, C.Y. Chen, C.H. Wang, and P. Zhou. 2012. Effects of different sowing depths on tuber yield and yield components of potato. Chinese Potato Journal 26 (5): 281–283.

Gu, F.W., Z.C. Hu, H.O. Wang, F.L. Ji, and Y.C. Tian. 2010. Design of a duck bill-roller peanut seeder and analysis of its trajectory. Chinese Agricultural Mechanization 4: 60–63.

Lawrence, M.J., D.R. Buckmaster, and W.J. Lamont Jr. 2007. A pneumatic dibbling machine for plastic mulch. Applied Engineering in Agriculture 23 (4): 419–424.

Li, M.F., Z.Z. Mai, L.G. Gui, J.W. Lu, and L. Yang. 2011. Effects of different plastic-film colors and mulching methods on dry matter accumulation and yield of potato. Ningxia Agriculture and Forestry Science and Technology 52 (3): 4–5.

Li, M.J., Y. Liu, Y.Y. Zhou, and L.Q. Zeng. 2013. Effects of different kind of plastic film and mulching methods on economic traits and yield of potato. Tillage and Cultivation 5: 37–38.

Li, X.R., L.R. Shi, W.Y. Zhao, and F. Dai. 2015. Design of double-track cam of direct insert corn planting furrow seeder for whole plastic-film mulching on double ridges. Journal of Hunan Agricultural University-Natural Sciences 41 (1): 94–98.

Liu, C.L., J.N. Song, and J.C. Wang. 2007. Study on hole former of peanut hill-drop planter mulching film. Journal of China Agricultural University 12 (3): 61–64.

Liu, J.D., W.B. Cao, D.Y. Tian, H.Y. Tang, and H.Z. Zhao. 2016. Kinematic analysis and experiment of planetary five-bar planting mechanism for zero-speed transplanting on mulch film. International Journal of Agricultural and Biological Engineering 9 (4): 84–91.

Liu, J.G., T.C. Wang, F.X. Yan, W.Y. Pan, and S.C. Huo. 2001. Design of film-mulching wheat hill seeder with vertical dropping mechanism. Transactions of the Chinese Society of Agricultural Engineering 17 (5): 55–58.

Lü, X.L., M.J. Liu, H.O. Wang, and Z.C. Hu. 2012. Research development of peanut seeding technology and equipment on the film. Chinese Agricultural Mechanization 01: 89–92.

Moden, W.L., Jr., T.W. Chappell, and F.H. Pitkin. 1977. An intermittent dibble-type container planter. Transactions of ASAE 21 (3): 455–459.

Munilla, R.D., and L.N. Shaw. 1987. A high speed dibbling transplanter. Transactions - American Society of Agricultural Engineers 30 (4): 904–908.

Ning, E.C., K.X. Zhu, D.Q. Yang, Y. Li, J.D. Li, and J.X. Jia. 2009. Virtual design and experiments of covering film and spraying parts of potato planter based on Solidworks. Journal of Agricultural Mechanization Research 31 (11): 133–136.

Qin, S.H., H.L. Dai, J.L. Zhang, and D. Wang. 2014. Effects of plastic film and ridge-furrow cropping patterns on soil nutrients movement and yield of potato in semiarid areas. Agricultural Research in the Arid Areas 32 (1): 38–41.

Wang, J.P. 2005. Study of framework and parameter of film mulching hill-drop planter, undergraduate thesis. Beijing, China: China Agricultural University.

Wang, Z.Y., D.J. Hu, and Y.R. Huang. 1988. The precision roller type hill-drop drill with the punching device on film. Transactions of the Chinese Society for Agricultural Machinery 1: 88–95.

Wei, H.A., and S.L. Shao. 2000. Analysis and evaluation on a roller type film mulching hill-drop planter for wheat. Journal of Gansu Agricultural University 35 (4): 419–423.

Wei, H.A., and S.L. Shao. 2001. Study on wheat hill-drop planter used for perpendicularly inserting film mulching field. Transactions of the Chinese Society for Agricultural Machinery 32 (6): 34–37.

Yang, L., S. Shi, T. Cui, D.X. Zhang, and N.N. Gao. 2012. Air-suction corn precision metering device with mechanical supporting plate to assist carrying seed. Transactions of the Chinese Society for Agricultural Machinery 43 (supp): 48–53.

Yue, Q., J.L. Jiang, C.L. Zhan, Z.Z. Li, and X.X. Sui. 2015. Design and test of multifunctional small potato planting machine. Journal of Agricultural Mechanization Research 37 (10): 128–131.

Zhao, H. 2012. Effect of ridge and furrow mulching with plastic film on yield and water usage in potato cultivation in the Dingxi semi-arid agroecosystem, doctoral dissertation. Lanzhou, China: Lanzhou University.

Zhao J. T, Zhao W.Y., Ren Y.H., and Niu H.H. 2010. Design and simulation of direct insert corn planting device of furrow seeder with whole plastic-film mulching on double ridges. Transactions of the Chinese Society for Agricultural Machinery 41(10): 40–43.

Zhao, W.Y., F. Dai, J. Yang, Z.L. Shi, Z. Yang, and L.R. Shi. 2013. Design and experiment of direct insert precision hill-seeder with corn whole plastic-film mulching on double ridges. Transactions of the Chinese Society for Agricultural Machinery 44 (11): 91–97.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (NSFC) (51765004), Scientific Research Project of Institutions of Higher Learning in Gansu Province (2017D-13) and Gansu Agricultural University, FuXi Talent Program GAUFX-02 J01.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, W., Simionescu, P.A. Parameter Analysis and Field Tests of a Double Crank Multi-Rod under Plastic-Film Hill-Drop Mechanism Potato Planter. Am. J. Potato Res. 97, 256–264 (2020). https://doi.org/10.1007/s12230-020-09773-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12230-020-09773-5