Abstract

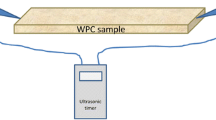

Relaxation behavior of natural fiber reinforced polymer composites exists in both solid and molten state and profoundly affects the control and optimization of processing parameters and dimensional accuracy of final products. The aim of this study was to establish an experimental estimating method to characterize relaxation behavior of polymer composite with traditional torque rheometer and investigate the effects of fiber concentration, dimension, and processing parameters on the relaxation behavior. Relaxation time of hemp fiber reinforced polypropylene composite were obtained by fitting the experimental torque data and corelated to the buckling deformation of packaging boxes manufactured by injection with the same injection parameters. The results show that all the increasing concentration of hemp fiber, higher rotor speed, and higher temperature can significantly decrease the relaxation time and result in a stable and better dimensional accuracy of injection packaging boxes. The finer fibers with the same weight concertation can bring an obvious reduction in relaxation time and buckling deformation. The proposed method for estimating relaxation behavior of polymer composite is a feasible and cost-effective way to investigate the viscoelastic properties of polymer composites close to the real processing conditions. And it can be widely used in optimization of processing parameters and performance of polymer composite products.

Similar content being viewed by others

References

G. F. Fernando, Mater. Charact., 59, 660 (2008).

G. Xun, Q. Li, W. Cheng, G. Han, and L. Xuan, Macromol. Res., 25, 141 (2017).

L. Brassart, L. Stainier, I. Doghri, and L. Delannay, Int. J. Plast., 36, 86 (2012).

H. J. Choi and S. S. Ray, J. Nanosci. Nanotechnol., 11, 8421 (2011).

P. Singha, K. Muthukumarappan, and P. Krishnan, Food Sci. Nutr., 6, 101 (2018).

L. L. Blyler and J. H. Daane, Polym. Eng. Sci., 7, 178 (2010).

J. Kajaks, K. Kalnins, and J. Matvejs, Key Eng. Mater., 762, 226 (2018).

J. G. Mallette and R. R. Soberanis, Polym. Eng. Sci., 38, 1436 (1998).

H. Zeng, J. Leng, J. Gu, and H. Sun, Mech. Mater., 124, 18 (2018).

A. Schiavi and A. Prato, Polym. Test., 59, 220 (2017).

H. Watanabe, Prog. Polym. Sci., 24, 1253 (1999).

C. M. Vu, D. D. Nguyen, H. S. Le, H. J. Choi, and T. D. Pham, Macromol. Res., 26, 54 (2018).

Q. Peng, Z. Zhu, C. Jiang, and H. Jiang, Adv. Ind. Eng. Polym. Res., 2, 61 (2019).

C. Luo, X. Shi, Z. Lei, C. Zhu, W. Zhang, and K. Yu, Polymer, 153, 43 (2018).

T. Roths, D. Maier, C. Friedrich, M. Marth, and J. Honerkamp, Rheol. Acta, 39, 163 (2000).

E. Kong, B. Yoon, J. D. Nam, and J. Suhr, Macromol. Res., 26, 998 (2018).

B. Cheng, C. Zhou, Y. Wei, and X. Sun, Polym. Test., 20, 811 (2001).

J. E. Goodrich and R. S. Porter, Polym. Eng. Sci., 7, 45 (1967).

M. Bousmina, A. Ait-Kadi, and J. B. J. Faisant, J. Rheol., 43, 415 (1999).

H. Elghannay, D. Tafti, and K. Yu, Int. J. Multiphas. Flow, 112, 100 (2019).

M. Farhadi, S. Fakhraee, and F. Akbari, J. Mol. Liq., 274, 246 (2019).

K. Li and G. Matsuba, Polymer, 171, 8 (2019).

B. Koohestani, I. Ganetri, and E. Yilmaz, Compos. Part B-Eng., 111, 103 (2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Acknowledgments: This work was supported by National Natural Science Foundation of China under grant 51973056, the key research and development plan of Hunan technology department under grant 2017WK2042, scientific research projects of Hunan provincial department of education under grant 18A258 and 18C0524, and Hunan provincial scientific research and innovation project under grant CX20190843 and CX20190844.

Rights and permissions

About this article

Cite this article

Jiang, T., Zeng, G. & Hu, C. Experimental Estimation of Relaxation Behavior for Hemp Fiber Reinforced Polypropylene Composite with Torque Rheometer. Macromol. Res. 28, 517–522 (2020). https://doi.org/10.1007/s13233-020-8059-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13233-020-8059-3