Abstract

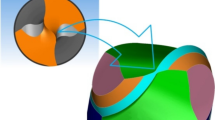

In order to extend the 2D-TRC (tool radius compensation) function of 3-axis CNC milling machines to ball end mills (BEMs), a new TRC named BEM-TRC is proposed to achieve successful milling of complex surfaces without over-cut. The implementation of the BEM-TRC for complex surfaces depicted in NURBS model is divided into three steps. The first one is to search the cutting point (CP) on a NURBS surface using equi-arc length interpolation in u or v direction. The second one is to accomplish BEM-TRC at the CP through offsetting the CP to the cutter center point (CCP) of a BEM along the normal vector at CP. The third one is to compute the cutter location point (CLP) of the BEM according to the BEM-CCP. The simulation and experiment verifies that the BEM-TRC is feasible and effective, and can avoid over-cut phenomenon successfully. The BEM-TRC extends the ability of the traditional 2D-TRC function, and makes 3-axis CNC milling machines to accomplish the milling process of complex NURBS surfaces.

Similar content being viewed by others

References

Chen, Z. C., & Fu, Q. (2007). A practical approach to generating steepest ascent tool-paths for three-axis finish milling of compound NURBS surfaces. Computer-Aided Design,39(11), 964–974.

Cheng, C.W., Tsa,i M.C., "Real-time variable feed rate NURBS curve interpolator for CNC machining," Int. J Adv. Manuf .Tech., Vol. 23, No. 11–12, pp. 865–873, 2004.

Li, Y., Chen, W., Cai, Y., Nasri, A., & Zheng, J. (2015). Surface skinning using periodic T-spline in semi-NURBS form. Journal of Computational and Applied Mathematics.,273, 116–131.

Ridwan, F., Xu, X., & Liu, G. (2010). A framework for machining optimisation based on STEP-NC. Journal of Intelligent Manufacturing,23, 423–441.

Xu, X. W. (2006). Realization of STEP-NC enabled machining. Robotics and Computer-Integrated Manufacturing,22(2), 144–153.

Lai, Y.-L. (2010). Tool-path generation of planar NURBS curves. Robotics and Computer-Integrated Manufacturing,26(5), 471–482.

Wang, Z. Q., & Wang, X. R. (2014). The principle and application of cutting-point virtual tool radius compensation for ellipsoidal outer contour finishing using a ball end mill. The International Journal of Advanced Manufacturing Technology,71(9–12), 1527–1537.

Yang, D. C. H., & Han, Z. (1999). Interference detection and optimal tool selection in 3-axis NC machining of free-form surfaces. Computer Aided Design,3, 303–315.

Yd, C., Hx, W., & Tm, W. (2011). Three-dimensional tool radius compensation for a 5-axis peripheral milling. Advanced Science Letters,26(4), 3093–3096.

Han, L., Gao, X. S., & Li, H. (2013). Space cutter radius compensation method for free form surface end milling. The International Journal of Advanced Manufacturing Technology.,67, 2563–2575.

Haitao, H., Dong, Y., Lixian, Z., & Han, L. (2009). Research on 3D Cutter Radius Compensation for 5-Axis End Milling. Chinese Journal of Mechanical Engineering.,15, 1770–1774.

Chu, Z. Y., Ahn, I. H., & Seung, K. (2017). Process monitoring and inspection systems in metal additive manufacturing: Status and applications. International Journal of Precision Engineering and Manufacturing-Green Technology,4(5), 235–245.

Park, D. H., & Kwon, H. H. (2016). Development of automobile engine mounting parts using hot-cold complex forging technology. International Journal of Precision Engineering and Manufacturing-Green Technology,3(2), 179–184.

Park, H. S., Dang, X. P., Nguyen, D. S., & Kumar, S. (2020). Design of advanced injection mold to increase cooling efficiency. International Journal of Precision Engineering and Manufacturing-Green Technology,7(2), 319–328.

Chu, C.-H., Wu, P.-H., & Lei, W.-T. (2010). Tool path planning for 5-axis flank milling of ruled surfaces considering CNC linear interpolation. Journal of Intelligent Manufacturing,23(3), 471–480.

Lin, B.-T., & Kuo, C.-C. (2009). Application of an integrated RE/RP/CAD/CAE/CAM system for magnesium alloy shell of mobile phone. Journal of Materials Processing Technology,209(6), 2818–2830.

Park, K., Kim, Y. S., Kim, C. S., & Park, H. J. (2007). Integrated application of CAD/CAM/CAE and RP for rapid development of a humanoid biped robot. Journal of Materials Processing Technology,187–188, 609–613.

Campatelli, G., Scippa, A., Lorenzini, L., & Sato, R. (2015). Optimal workpiece orientation to reduce the energy consumption of a milling process. International Journal of Precision Engineering and Manufacturing-Green Technology,2(1), 5–13.

Lorenzo-Yustos, H., Lafont, P., Diaz Lantada, A., Navidad, A. F.-F., et al. (2010). Towards complete product development teaching employing combined CAD-CAM-CAE technologies. Computer Applications in Engineering Education,18(4), 661–668.

Piegl, L., & Tiller, W. (2012). The NURBS Book. Berlin: Springer.

Wang, Y. S., Wang, X. R., Wang, Z. Q., Lin, T. S., & He, P. (2017). Preparation and microstructure of AlCoCrFeNi high-entropy alloy complex curve coatings. Materials Science and Technology,33(5), 559–566.

Wang, X. R., Wang, Z. Q., Wang, Y. S., Lin, T. S., & He, P. (2017). A bisection method for the milling of NURBS mapping projection curves by CNC machines. The International Journal of Advanced Manufacturing Technology,91(1–4), 155–164.

Acknowledgements

This project is supported by National Science and Technology Major Project (2017-VII-0003–0096-4, 2017-VII-0012–0108), National Natural Science Foundation of China (Grant no. 51764038 and 51465030), Gansu Science and Technology Planning Project (17YF1GA018, 17CX1JA117, and 18JR3RA132), Western Young Scholars of Chinese Academy of Sciences, Lanzhou Talent Innovation and Entrepreneurship Project (2019-RC-102 and 2018-RC-108), Longyuan Youth Innovative and Entrepreneurial Talents Project, Foundation of A Hundred Youth Talents Training Program of Lanzhou Jiaotong University, and Gansu Provincial Employee Technology Innovation Subsidy Fund Project.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A

Appendix A

The parameters of P, w, U, V, p and q for the NURBS surface shown in Fig. 2 are listed as follows. P is control point, w is weight, U and V are kont vectors, and p and q is degree.

-

P = {[30 0 0], [30 − 30 0] , [0 − 30 0], [− 30 − 30 0], [− 30 0 0], [− 30 30 0], [0 30 0], [30 30 0], [30 0 0]; [26 0 3], [26 − 26 3], [0 − 26 3], [− 27 − 27 1], [− 27 0 1], [− 27 27 1], [0 26 3], [26 26 3], [26 0 3]; [24 0 3], [24 − 24 3], [0 − 22 3], [− 24 − 24 3], [− 24 0 3], [− 24 24 3], [0 22 3], [24 24 3],[24 0 3];

-

[21 0 4], [ 21 − 21 4], [0 − 18 4], [− 21 − 21 4], [− 21 0 4], [− 21 21 4], [0 18 4], [21 21 4], [21 0 4]; [19 0 4], ]19 − 19 4],[0 − 14 4], [− 18 − 18 4], [− 18 0 4], [− 18 18 4],[0 14 4],[19 19 4],[19 0 4]; [15 0 3.5],[15 − 15 3.5], [0 − 10 3.5], [− 15 − 15 3.5], [− 15 0 3.5], [− 15 15 3.5],[0 10 3.5],[15 15 3.5],[15 0 3.5]; [12 0 3],[12 − 12 3], [0 − 7 3], [− 12 − 12 3], [− 12 0 3], [− 12 12 3],[0 7 3],[12 12 3],[12 0 3]; [7 0 2], [7 − 7 2],[0 − 4 2], [− 9 − 9 2], [− 9 0 2], [− 9 9 2], [0 4 2], [7 7 2], [7 0 2]; [− 5 0 2], [− 5 0 2], [− 5 0 2], [− 5 0 2], [− 5 0 2], [− 5 0 2], [− 5 0 2], [− 5 0 2], [− 5 0 2]};

-

w = [1 0.707 1 0.707 1 0.707 1 0.707 1; 1 0.707 1 0.707 1 0.707 1 0.707 1; 1 0.707 1 0.707 1 0.707 1 0.707 1; 1 0.707 1 0.707 1 0.707 1 0.707 1; 1 0.707 1 0.707 1 0.707 1 0.707 1; 1 0.707 1 0.707 1 0.707 1 0.707 1; 1 0.707 1 0.707 1 0.707 1 0.707 1; 1 0.707 1 0.707 1 0.707 1 0.707 1; 1 0.707 1 0.707 1 0.707 1 0.707 1];

-

U = [0 0 0 1/4 1/4 1/2 1/2 3/4 3/4 1 1 1];

-

V = [0 0 0 1/4 1/4 1/2 1/2 3/4 3/4 1 1 1];

-

p = 2;

-

q = 2.

Rights and permissions

About this article

Cite this article

Wang, Z., Wang, X., Wang, Y. et al. Ball End Mill—Tool Radius Compensation of Complex NURBS Surfaces for 3-Axis CNC Milling Machines. Int. J. Precis. Eng. Manuf. 21, 1409–1419 (2020). https://doi.org/10.1007/s12541-020-00345-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-020-00345-5