Abstract

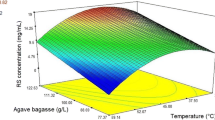

The enzymatic hydrolysis of sugarcane bagasse cellulose (SBC) was performed after acid/peroxide-alkali (APA) pretreatment, soda/AQ pulping, and bleaching steps for producing glucose. Cellic® CTec3 (CT) and Celluclast®1.5L (CL) complexes were evaluated in both individual and mixed systems for observing their influence in cellulose conversion. Deconvolution of XRD patterns and SEM images proved the low crystallinity and high accessibility of SBC, thus being able to provide significantly higher glucose yield than the commercial cellulose with predominant Iβ polymorphism. The analysis of variance (ANOVA) and the response surface methodology (RSM), applied to a full factorial 24 design of experiments built for assessing the activity of CT and CL enzymes together in the hydrolytic system, were accurate in describing that the feedstock (SBC or commercial cellulose) and the treatment of cellulose are the factors with major effect on the saccharification efficiency (F = 744.12, p < 0.0001), thus predicting 53.71 g/L maximum glucose yield for the experimental conditions studied (near to the maximum yield reached, 55.77%) when using SBC, more than double the conversion reached for commercial cellulose, and showing the cooperative work of both complexes together for converting cellulose.

Graphical abstract

Similar content being viewed by others

References

Zhou Z, Lei F, Li P, Jiang J (2018) Lignocellulosic biomass to biofuels and biochemicals: a comprehensive review with a focus on ethanol organosolv pretreatment technology. Biotechnol Bioeng 115:2683–2702. https://doi.org/10.1002/bit.26788

Gallo JMR, Trapp MA (2017) The chemical conversion of biomass-derived saccharides: an overview. J Braz Chem Soc 28:1586–1607. https://doi.org/10.21577/0103-5053.20170009

Meléndez-Hernández PA, Hernández-Beltrán JU, Hernández-Guzmán A, Morales-Rodríguez R, Torres-Guzmán JC, Hernández-Escoto H (2019) Comparative of alkaline hydrogen peroxide pretreatment using NaOH and Ca(OH)2 and their effects on enzymatic hydrolysis and fermentation steps. Biomass Convers Bior. https://doi.org/10.1007/s13399-019-00574-3

Hashmi M, Shah AA, Hameed A, Ragauskas AJ (2017) Enhanced production of bioethanol by fermentation of autohydrolyzed and C4mimOAc-treated sugarcane bagasse employing various yeast strains. Energies 10:1–7. https://doi.org/10.3390/en10081207

Nakasone K, Kobayashi T (2016) Effect of pre-treatment of sugarcane bagasse on the cellulose solution and application for the cellulose hydrogel films. Biotechnol Bioeng 27:973–980. https://doi.org/10.1002/pat.3757

Centi G, Lanzafame P, Perathoner S (2011) Analysis of the alternative routes in the catalytic transformation of lignocellulosic materials. Catal Today 167:14–30. https://doi.org/10.1016/j.cattod.2010.10.099

Kim S, Kim CH (2013) Bioethanol production using the sequential acid/alkali-pretreated empty palm fruit bunch fiber. Renew Energy 54:150–155. https://doi.org/10.1016/j.renene.2012.08.032

Yu Z, Jameel H, Chang H-M, Philips R, Park S (2011) Evaluation of the factors affecting avicel reactivity using multi-stage enzymatic hydrolysis. Biotechnol Bioeng 109:1131–1139. https://doi.org/10.1002/bit.24386

Zabed H, Sahu JN, Boyce AN, Faruq G (2016) Fuel ethanol production from lignocellulosic biomass: an overview on feedstocks and technological approaches. Renew Sust Energ Rev 66:751–774. https://doi.org/10.1016/j.rser.2016.08.038

Robak K, Balcerek M (2018) Review of second generation bioethanol production from residual biomass. Food Technol Biotechnol 56:174–187. https://doi.org/10.17113/ftb.56.02.18.5428

Yan Y, Zhang C, Lin Q, Wang X, Cheng B, Li H, Ren J (2018) Microwave-assisted oxalic acid pretreatment for the enhancing of enzyme hydrolysis in the production of xylose and arabinose from bagasse. Molecules 23:1–13. https://doi.org/10.3390/molecules23040862

Moura HOMA, Campos LMA, da Silva VL, de Andrade JCF, de Assumpção SMN, Pontes LAM, de Carvalho LS (2018) Investigating acid/peroxide-alkali pretreatment of sugarcane bagasse to isolate high accessibility cellulose applied in acetylation reactions. Cellulose 25:5669–5685. https://doi.org/10.1007/s10570-018-1991-0

Macrelli S, Galbe M, Wallberg O (2014) Effects of production and market factors on ethanol profitability for an integrated first and second generation ethanol plant using the whole sugarcane as feedstock. Biotechnol Bioeng 7:1–16. https://doi.org/10.1186/1754-6834-7-26

Hernández-Beltrán JU, Fontalvo J, Hernández-Escoto H (2020) Fed-batch enzymatic hydrolysis of plantain pseudostem to fermentable sugars production and the impact of particle size at high solids loadings. Biomass Convers Bior. https://doi.org/10.1007/s13399-020-00669-2

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101:4851–4861. https://doi.org/10.1016/j.biortech.2009.11.093

Agbor VB, Cicek N, Sparling R, Berlin A, Levin DB (2011) Biomass pretreatment: fundamentals toward application. Biotechnol Adv 59:675–685. https://doi.org/10.1016/j.biotechadv.2011.05.005

Rabelo SC, Andrade RR, Maciel Filho R, Costa AC (2014) Alkaline hydrogen peroxide pretreatment, enzymatic hydrolysis and fermentation of sugarcane bagasse to ethanol. Fuel 136:349–357. https://doi.org/10.1016/j.fuel.2014.07.033

de Assumpção SMN, Pontes LAM, de Carvalho LS, Campos LMA, de Andrade JCF, da Silva EG (2016) Pré-tratamento combinado H2SO4/H2O2/NaOH para obtenção das frações lignocelulósicas do bagaço da cana-de-açúcar. Rev Virt Quím 8:803–822. https://doi.org/10.5935/1984-6835.20160059

Mesa L, González E, Cara C, Ruiz E, Castro E, Mussatto SI (2010) An approach to optimization of enzymatic hydrolysis from sugarcane bagasse based on organosolv pretreatment. J Chem Technol Biotechnol 85:1092–1098. https://doi.org/10.1002/jctb.2404

Candido RG, Mori NR, Gonçalves AR (2019) Sugarcane straw as feedstock for 2G ethanol: evaluation of pretreatmentsand enzymatic hydrolysis. Ind Crop Prod 142:111845. https://doi.org/10.1016/j.indcrop.2019.111845

Nielsen F, Galbe M, Zacchi G, Wallberg O (2019) The effect of mixed agricultural feedstocks on steam pretreatment, enzymatic hydrolysis, and cofermentation in the lignocellulose-to-ethanol process. Biomas Conv Bioref. https://doi.org/10.1007/s13399-019-00454-w

dos Santos AC, Ximenes E, Kim Y, Ladisch MR (2018) Lignin–enzyme interactions in the hydrolysis of lignocellulosic biomass. Trends Biotechnol 37:518–531. https://doi.org/10.1016/j.tibtech.2018.10.010

Binod P, Gnansounou E, Sindhu R, Pandey A (2019) Enzymes for second generation biofuels: recent developments and future perspectives. Bioresour Technol Rep 5:317–325. https://doi.org/10.1016/j.biteb.2018.06.005

Li H, Chen X, Xiong L, Luo M, Chen X, Wang C, Huang C, Chen X (2019) Stepwise enzymatic hydrolysis of alkaline oxidation treated sugarcane bagasse for the co-production of functional xylo-oligosaccharides and fermentable sugars. Bioresour Technol 275:345–351. https://doi.org/10.1016/j.biortech.2018.12.063

Sluiter A, Hame B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. Laboratory analytical procedure. NREL 1617:1–16

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Bioeng 3:1–10. https://doi.org/10.1186/1754-6834-3-10

Scherrer P (1918) Bestimmung der inneren Struktur und der Größe von Kolloidteilchen mittels Röntgenstrahlen. Nachrichten von der Gesellschaft der Wissenschaften 2:98–100. https://doi.org/10.1007/978-3-662-33915-2_7

Palmqvist E, Hahn-Hägerdal B (2000) Fermentation of lignocellulosic hydrolysates. I: inhibition an detoxification. Bioresour Technol 74:17–24. https://doi.org/10.1016/S0960-8524(99)00160-1

Rezende CA, de Lima M, Maziero P, de Azevedo E, Garcia W, Polikarpov I (2011) Chemical and morphological characterization of sugarcane bagasse submitted to a delignification process for enhanced enzymatic digestibility. Biotechnol Bioeng 54(4):1–18 http://www.biotechnologyforbiofuels.com/content/4/1/54

Singh R, Tiwari S, Srivastava M, Shukla A (2014) Experimental study on the performance of microwave assisted hydrogen peroxide (H2O2) pretreatment of rice straw. Agric Eng Int CIGR J 16:173–181 http://www.cigrjournal.org/index.php/Ejounral/article/view/2633

da Cruz AC, da Silva MC, Ribeiro SD, Filho GR, de Assunção RMN, Cerqueira DA (2011) Utilização do acetato de celulose produzido a partir da celulose extraída do caroço de manga como matriz para produção de sistemas microparticulados. Quím Nova 34:385–389. https://doi.org/10.1590/S0100-40422011000300004

Su Y, Du R, Guo H, Cao M, Wu Q, Su R, Qi W, He Z (2015) Fractional pretreatment of lignocellulose by alkaline hydrogen peroxide: characterization of its major components. Food Bioprod Process 94:322–330. https://doi.org/10.1016/j.fbp.2014.04.001

Cheng G, Varanasi P, Li C, Liu H, Melnichenko YB, Simmons BA, Singh S (2011) Transition of cellulose crystalline structure and surface morphology of biomass as a function of ionic liquid pretreatment and its relation to enzymatic hydrolysis. Biomacromology 12:933–941. https://doi.org/10.1021/bm101240zf

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

Horikawa Y (2017) Assessment of cellulose structural variety from different origins using near infrared spectroscopy. Cellulose 24:5313–5325. https://doi.org/10.1007/s10570-017-1518-0

Barud HS, Araújo AM Jr, Santos DB, Assuncão RMN, Meireles CS, Cerqueira DA, Rodrigues Filho G, Ribeiro CA, Messaddeq Y, Ribeiro SJL (2008) Thermal behavior of cellulose acetate produced from homogeneous acetylation of bacterial cellulose. Thermochim Acta 471:61–69. https://doi.org/10.1016/j.tca.2008.02.009

Akinwande MO, Dikko HG, Samson A (2015) Variance inflation factor: as a condition for the inclusion of suppressor variable(s) in regression analysis. Open J Stat 5:754–767. https://doi.org/10.4236/ojs.2015.57075

Manasa P, Saroj P, Korrapati N (2018) Ultrasound-assisted alkaline pretreatment to intensify enzymatic saccharification of Crotalaria juncea using a statistical method. Biomass Convers Bior 8:659–668. https://doi.org/10.1007/s13399-018-0324-8

Rambo DF, Biegelmeyer R, Toson NSB, Dresch RR, Moreno PRH, Henriques AT (2019) Box–Behnken experimental design for extraction optimization of alkaloids from Erythrina verna Vell. trunk barks and LC method validation. Ind Crop Prod 133:250–258. https://doi.org/10.1016/j.indcrop.2019.03.030

Fockink DH, Andreaus J, Ramos LP, Lukasik RM (2020) Pretreatment of cotton spinning residues for optimal enzymatic hydrolysis: a case study using green solvents. Renew Energy 145:490–499. https://doi.org/10.1016/j.renene.2019.06.042

Seifollahi M, Amiri H (2019) Enzymatic post-hydrolysis of water-soluble cellulose oligomers released by chemical hydrolysis for cellulosic butanol production. Cellulose 26:4479–4494. https://doi.org/10.1007/s10570-019-02397-x

Kaschuk JJ, Lacerda TM, Frollini E (2019) Investigating effects of high cellulase concentration on the enzymatic hydrolysis of the sisal cellulosic pulp. Int J Biol Macromol 138:919–926. https://doi.org/10.1016/j.ijbiomac.2019.07.173

Cornejo A, Alegria-Dallo I, García-Yoldi I, Sarobe I, Sánchez D, Otazu E, Funcia I, Gil MJ, Martínez-Merino V (2019) Pretreatment and enzymatic hydrolysis for the efficient production of glucose and furfural from wheat straw, pine and poplar chips. Bioresour Technol 288:121583. https://doi.org/10.1016/j.biortech.2019.121583

Rodrigues AC, Haven MØ, Lindedam J, Felby C, Gama M (2015) Celluclast and Cellic® CTec2: saccharification/fermentation of wheat straw, solid–liquid partition and potential of enzyme recycling by alkaline washing. Enzym Microb Technol 79:70–77. https://doi.org/10.1016/j.enzmictec.2015.06.019

Lu M, Li J, Han L, Xiao W (2019) An aggregated understanding of cellulase adsorption and hydrolysis for ball-milled cellulose. Bioresour Technol 273:1–7. https://doi.org/10.1016/j.biortech.2018.10.037

Malgas S, Thoresen M, Van Dyk JS, Pletschk BI (2017) Time dependence of enzyme synergism during the degradation of model and natural lignocellulosic substrates. Enzym Microb Technol 103:1–11. https://doi.org/10.1016/j.enzmictec.2017.04.007

Acknowledgments

The authors acknowledge the support provided by the Post-Graduate Programs PPGE/UNIFACS, PPGQ/UFRN, PPEQ/UFBA, and PPGEQ/UFSCar.

Funding

This study was financed by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES – Brazil) - Finance Code 001 and the Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPQ – Brazil).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(PDF 184 kb).

Rights and permissions

About this article

Cite this article

Campos, L.M.A., Moura, H.O.M.A., Cruz, A.J.G. et al. Response surface methodology (RSM) for assessing the effects of pretreatment, feedstock, and enzyme complex association on cellulose hydrolysis. Biomass Conv. Bioref. 12, 2811–2822 (2022). https://doi.org/10.1007/s13399-020-00756-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00756-4