Abstract

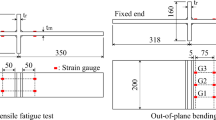

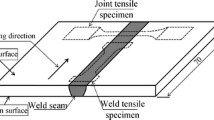

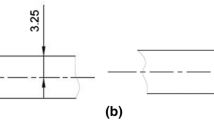

This study investigated the applicability of low transformation temperature (LTT) arc welding consumables to improve fatigue strength against weld root failure. Transverse attachment joints formed by single-sided welding, similar to rib-to-deck connections in orthotropic steel bridge decks, were fabricated using an LTT welding consumable and conventional welding consumable. Fatigue tests were performed with out-of-plane bending loads using a vibration-type fatigue testing machine. The test results indicated that higher fatigue strength can be achieved in the joint with an LTT consumable compared with a conventional one. In addition, residual stresses around the weld bead were clarified by X-ray diffraction measurements and finite element analyses. The results revealed that the LTT consumable weld metal can reduce residual stress around the weld and also introduce compressive residual stress to the weld root, which can contribute to improved fatigue strength.

Similar content being viewed by others

References

Maddox SJ (1974) Fatigue of welded joints loaded in bending, Supplementary Report 84UC. Transport and Road Research Laboratory, Structures Department, Bridges Design Division, Crowthorne, Berkshire

Federal Highway Administration (2012) Manual for design, construction, and maintenance of orthotropic steel deck bridges, FHWA-IF-12-027

Hirohata M (2017) Effect of post weld heat treatment on steel plate deck with trough rib by portable heat source. Weld World 61(6):1225–1235

Ohta A, Watanabe O, Matsuoka K, Siga C, Nishijima S, Maeda Y, Suzuki N, Kubo T (1999) Fatigue strength improvement by using newly developed low transformation temperature welding material. Weld World 43:38–42

Ohta A, Maeda Y, Nguyen NT, Suzuki N (2000) Fatigue strength improvement of box section beam by low transformation temperature welding wire. Weld World 44:26–30

Ohta A, Watanabe O, Matsuoka K, Maeda Y, Suzuki N, Kubo T (2000) Fatigue strength improvement of box welds by low transformation temperature welding wire and PWHT. Weld World 44:52–56

Ohta A, Suzuki N, Maeda Y, Maddox SJ (2003) Fatigue strength improvement of lap welded joints by low transformation temperature welding wire—superior improvement with strength of steel. Weld World 47(3–4):38–43

Lixing H, Dongpo W, Wenxian W, Yufeng Z (2004) Ultrasonic peening and low transformation temperature electrodes used for improving the fatigue strength of welded joints. Weld World 48(3–4):34–39

Barsoum Z, Gustafsson M (2009) Fatigue of high strength steel joints welded with low temperature transformation consumables. Eng Fail Anal 16:2186–2194

Bhattia AA, Barsoum Z, van der Mee V, Kromm A, Kannengiesser T (2013) Fatigue strength improvement of welded structures using new low transformation temperature filler materials. Procedia Eng 66:192–201

Harati E, Karlsson L, Svensson LE, Dalaei K (2017) Applicability of low transformation temperature welding consumables to increase fatigue strength of welded high strength steels. Int J Fatigue 97:39–47

Miki C, Anami K (2001) Improving fatigue strength by additional welding with low temperature transformation welding electrodes. Steel Struc 1:25–32

Ohta A, Suzuki N, Maeda Y (2003) Extension of fatigue life by additional welds around box welds using low transformation temperature welding material, High Performance Materials in Bridges. ASCE, pp 219–226

Japan Road Association (2017) Specifications for highway bridges, part II. (in Japanese)

Yamada K, Ya S, Baik B, Torii A, Ojio T, Yamada S (2007) Development of a new fatigue testing machine and some fatigue tests for plate bending, IIW documentation, XIII-2161-07

Yamada K, Ishikawa T, Kakiichi T, Murai K, Yamada S (2009) Fatigue tests of various welded joints in plate bending, IIW documentation, XIII-2290r1-09

Hattori M, Makita T, Tateishi K, Hanji T, Shimizu M, Yagi N (2018) Crack sizing accuracy of a phased array ultrasonic scanner developed for inspection of rib-to-deck welded joints in orthotropic steel decks. J Jpn Soc Civ Eng Ser A1 74(3):516–530 (in Japanese)

Japanese Society of Steel Construction (2012) Fatigue design recommendations for steel structures (in Japanese)

Kim YC, Lee JY, Inose K (2005) The high accurate prediction of welding distortion generated by fillet welding. Q J Jpn Weld Soc 23(3):431–435 (in Japanese)

Mikami Y, Morikage Y, Mochizuki M, Toyoda M (2006) Measurement and numerical simulation of angular distortion of fillet welded T-joints—welding angular distortion control by transformation expansion of weld metals (report 1). Q J Jpn Weld Soc 24(4):312–323 (in Japanese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XVI - Polymer Joining and Adhesive Technology

Rights and permissions

About this article

Cite this article

Hanji, T., Tateishi, K., Kano, S. et al. Fatigue strength of transverse attachment steel joints with single-sided arc weld using low transformation temperature welding consumable. Weld World 64, 1293–1301 (2020). https://doi.org/10.1007/s40194-020-00915-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-00915-1