Abstract

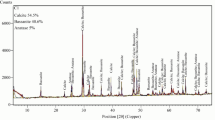

Ethanolysis of soybean oil was carried out over lime catalyst produced by calcination of scallop shells food wastes. The as prepared catalyst showed XRD lines belonging to lime, whereas post reaction samples presented XRD pattern belonging to Ca(OH)2 overlaid with lines of calcium diglyceroxide. The catalyst dynamics during ethanolysis was similar to that reported for methanolysis, being hydration and consequent diglyceroxide formation the main transformations of CaO catalyst during reaction. The influence of the reaction parameters, such as ethanol:oil molar ratio (10:1–14:1), catalyst loading (10–15%, based in oil weight) and time reaction (6–10 h), on the FAAE (fatty acids ethyl esters) yield was analyzed by response surface methodology. A polynomial model was fitted using Minitab software, showing a correlation between predicted and experimental FAEE yields of 0.921. The maximum FAEE yield of 99.2% was computed for optimal reaction parameters of 11:1 ethanol:oil molar ratio; 13.8% catalyst loading and 9.1 h of reaction time. The fitted model was verified for the optimal conditions, using three replicas, given 99.0% of FAEE yield instead of the 99.2% predicted.

Similar content being viewed by others

References

Directorate-General for Research and Innovation (European Commission) JRC (European C (2017) The Strategic Energy Technology (SET) Plan—EU Law and Publications

Moser BR (2009) Biodiesel production, properties, and feedstocks. Vitro Cell Dev Biol Plant 45:229–266

Huang D, Zhou H, Lin L (2011) Biodiesel: an alternative to conventional fuel. Energy Procedia 16:1874–1885. https://doi.org/10.1016/j.egypro.2012.01.287

Avramović JM, Veličković AV, Stamenković OS et al (2015) Optimization of sunflower oil ethanolysis catalyzed by calcium oxide: RSM versus ANN-GA. Energy Convers Manag 105:1149–1156. https://doi.org/10.1016/j.enconman.2015.08.072

Borges ME, Díaz L (2012) Recent developments on heterogeneous catalysts for biodiesel production by oil esterification and transesterification reactions: a review. Renew Sustain Energy Rev 16:2839–2849. https://doi.org/10.1016/j.rser.2012.01.071

Dalena F, Senatore A, Marino A et al (2017) Methanol production and applications: an overview. In: Basile A (ed) Methanol: science and engineering. Elsevier B.V, London, pp 3–28

Sarkar N, Ghosh SK, Bannerjee S, Aikat K (2012) Bioethanol production from agricultural wastes: an overview. Renew Energy 37:19–27. https://doi.org/10.1016/j.renene.2011.06.045

Watcharathamrongkul K (2010) Calcium oxide based catalysts for ethanolysis of soybean oil. Songklanakarin J Sci Technol 32:627–634

Vujicic D, Comic D, Zarubica A et al (2010) Kinetics of biodiesel synthesis from sunflower oil over CaO heterogeneous catalyst. Fuel 89:2054–2061. https://doi.org/10.1016/j.fuel.2009.11.043

Verma P, Sharma MP (2016) Comparative analysis of effect of methanol and ethanol on Karanja biodiesel production and its optimisation. Fuel 180:164–174. https://doi.org/10.1016/j.fuel.2016.04.035

García M, Gonzalo A, Sánchez JL et al (2011) Metanolysis and ethanolysis of animal fats: a comparative study of the influence of alcohols. Chem Ind Chem Eng Q 17:91–97. https://doi.org/10.2298/CICEQ100224058G

Rashid U, Ibrahim M, Ali S et al (2012) Comparative study of the methanolysis and ethanolysis of Maize oil using alkaline catalysts. Grasas Aceites 63:35–43. https://doi.org/10.3989/gya.06891

Meneghetti SMP, Meneghetti MR, Wolf CR et al (2006) Biodiesel from castor oil: a comparison of ethanolysis versus methanolysis. Energy Fuels 20:2262–2265. https://doi.org/10.1021/ef060118m

Bolonio D, García-Martínez MJ, Ortega MF et al (2019) Fatty acid ethyl esters (FAEEs) obtained from grapeseed oil: a fully renewable biofuel. Renew Energy 132:278–283. https://doi.org/10.1016/j.renene.2018.08.010

Rubio-Caballero JM, Santamaría-González J, Mérida-Robles J et al (2013) Calcium zincate derived heterogeneous catalyst for biodiesel production by ethanolysis. Fuel 105:518–522. https://doi.org/10.1016/j.fuel.2012.09.054

Kaur N, Ali A (2014) Kinetics and reusability of Zr/CaO as heterogeneous catalyst for the ethanolysis and methanolysis of Jatropha crucas oil. Fuel Process Technol 119:173–184. https://doi.org/10.1016/j.fuproc.2013.11.002

Kaur N, Ali A (2015) Biodiesel production via ethanolysis of jatropha oil using molybdenum impregnated calcium oxide as solid catalyst. RSC Adv 5:13285–13295. https://doi.org/10.1039/c4ra14786c

Velickovic A, Avramovic J, Stamenkovic O, Veljkovic V (2016) Kinetics of the sunflower oil ethanolysis using CaO as catalyst. Chem Ind Chem Eng Q 22:409–418

Kaur M, Ali A (2014) Ethanolysis of waste cottonseed oil over lithium impregnated calcium oxide: kinetics and reusability studies. Renew Energy 63:272–279. https://doi.org/10.1016/j.renene.2013.09.024

Anastopoulos G, Dodos GS, Kalligeros S, Zannikos F (2013) Biodiesel production by ethanolysis of various vegetable oils using calcium ethoxide as a solid base catalyst. Int J Green Energy 10:468–481. https://doi.org/10.1080/15435075.2012.674081

Živković SB, Veljković MV, Banković-Ilić IB et al (2017) Technological, technical, economic, environmental, social, human health risk, toxicological and policy considerations of biodiesel production and use. Renew Sustain Energy Rev 79:222–247. https://doi.org/10.1016/j.rser.2017.05.048

Chumuang N, Punsuvon V (2017) Response surface methodology for biodiesel production using calcium methoxide catalyst assisted with tetrahydrofuran as cosolvent. J Chem. https://doi.org/10.1155/2017/4190818

Silva GF, Camargo FL, Ferreira ALO (2011) Application of response surface methodology for optimization of biodiesel production by transesterification of soybean oil with ethanol. Fuel Process Technol 92:407–413. https://doi.org/10.1016/j.fuproc.2010.10.002

Razack SA, Duraiarasan S (2016) Response surface methodology assisted biodiesel production from waste cooking oil using encapsulated mixed enzyme. Waste Manag 47:98–104. https://doi.org/10.1016/j.wasman.2015.07.036

Babaki M, Yousefi M, Habibi Z, Mohammadi M (2017) Process optimization for biodiesel production from waste cooking oil using multi-enzyme systems through response surface methodology. Renew Energy 105:465–472. https://doi.org/10.1016/j.renene.2016.12.086

Catarino M, Ramos M, Dias APS et al (2017) Calcium rich food wastes based catalysts for biodiesel production. Waste Biomass Valoriz 8:1699–1707. https://doi.org/10.1007/s12649-017-9988-8

Zagonel GF, Peralta-Zamora P, Ramos LP (2004) Multivariate monitoring of soybean oil ethanolysis by FTIR. Talanta 63:1021–1025. https://doi.org/10.1016/j.talanta.2004.01.008

Avhad MR, Sánchez M, Bouaid A et al (2016) Modeling chemical kinetics of avocado oil ethanolysis catalyzed by solid glycerol-enriched calcium oxide. Energy Convers Manag 126:1168–1177. https://doi.org/10.1016/j.enconman.2016.07.060

Soares Dias AP, Puna J, Gomes J et al (2016) Biodiesel production over lime. Catalytic contributions of bulk phases and surface Ca species formed during reaction. Renew Energy 99:622–630. https://doi.org/10.1016/J.RENENE.2016.07.033

Catarino M, Martins S, Soares Dias AP et al (2019) Calcium diglyceroxide as a catalyst for biodiesel production. J Environ Chem Eng. https://doi.org/10.1016/j.jece.2019.103099

Fujimoto K (1992) FTIR spectroscopic study of C02 adsorption/desorption on MgO/CaO catalysts. J Phys Chem 9038:9035–9038. https://doi.org/10.1021/j100201a063

Acknowledgements

The authors acknowledge FCT (Fundacão para a Ciência e Tecnologia. Portugal) for funding project PTDC/EMS-ENE/4865/2014.This work was partially supported by FCT, through IDMEC, under LAETA, project FCT UID/EMS/50022/2019.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ramos, M., Soares Dias, A.P. & Teodoro, F. Soybean oil ethanolysis over Ca based catalyst. Statistical optimization of reaction conditions. Reac Kinet Mech Cat 130, 433–445 (2020). https://doi.org/10.1007/s11144-020-01791-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-020-01791-y