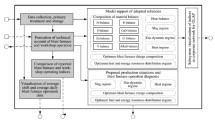

Expert systems that recognize the state of a blast furnace, ensure its operational stability, and reduce the production costs are considered. An expert system based on a production model of knowledge representation is proposed. The knowledge is extracted from field data, blast-furnace operating experience, and iron production operating procedures. The informative features are represented as trajectories with pronounced trends for the knowledge base of the expert system. They were obtained using a case-based approach, field data filtration, grouping, and sorting, and an expert evaluation method.

Similar content being viewed by others

References

D. Bettinger, H. Fritschek, T. Kronberger, et al., “VAIRON blast furnace process optimization—25 years of experience with closedloop expert systems,” in: 7th European Coke and Ironmaking Congr. (ECIC 2016), Austrian Society for Metallurgy and Materials (ASMET), Linz, AT (2016), pp. 317–333.

A. Klinger, T. Kronberger, M. Schaler, et al., “Expert systems controlling the iron making process in closed loop operation,” in: Expert Systems, IntechOpen, Croatia (2010), pp. 117–136.

V. I. Bol’shakov, I. G. Murav’eva, D. N. Togobitskaya, et al., “Expert systems for blast-furnace smelting control,” Chern. Metallurg., No. 9, 25–32 (2015).

N. A. Spirin (ed.), Yu. V. Ipatov, V. I. Lobanov, et al., Information Systems in Metallurgy [in Russian], UGTU-UPI, Ekaterinburg (2001).

S. Wakisaka, N. Sumida, H. Nakashima, and Y. Tetsu, “Development of expert system building tool for real-time control system – FAIN,” Nippon Steel Technical Report, No. 57, 79–85 (1993).

R. Mizoguchi, “Japanese expert system development,” in: Proc. Korea/Japan Joint Conf. on Expert System, Seoul (1993), pp. 17–50.

I. Carmichael, C. Thirion, R. Goffin, et al., “The evolution of modern blast furnace plant and equipment and the introduction of knowledge engineering,” Stal’, No. 12, 8–14 (2006).

G. Carayannis, “Artificial intelligence and expert systems in the steel industry,” JOM,45, No. 10, 43–51 (1993).

S. Amano, T. Takarabe, T. Nakamori, et al., “Expert system for blast furnace operation at Kimitsu Works,” ISIJ Int.,30, No. 2, 105–110 (1990).

R. Nakajima et al., “Operation control of a blast furnace by artificial intelligence,” in: Proc. 46th AIME Ironmaking Conf., ISS, Warrendale, PA (1987), pp. 209–216.

L. V. Portnov, V. V. Titov, L. D. Nikitin, and V. G. Shchipitsyn, “Improvement of blast-furnace PCS,” Stal’, No. 7, 18–20 (2014).

V. I. Solov’ev, V. A. Krasnobaev, Yu. A. Sarapulov, and E. A. Pavlov, “Expert system for diagnostics and control of blast-furnace operation,” in: Proc. Int. Sci.-Tech. Conf. on Theory and Practice of Iron Production [in Russian], Izd. Krivorozhskogo Tekhn. Univ., Krivoi Rog (2004), pp. 484–487.

V. G. Lisienko and Yu. V. Kryuchenkov, Improvement of Power Technologies and Production, Vol. 3, Book 1: Automated Control, Information Science, and Diagnostics. Processes and Power Engineering (Monograph) [in Russian], UMTs UPI, Ekaterinburg (2017).

A. S. Istomin, N. A. Spirin, V. V. Lavrov, and M. A. Byakova, “Developing software for diagnostics of blast-furnace operation upset,” Vestn. Tomsk. Gos. Univ., No. 3 (36), 97–102 (2016).

E. B. Ivanov, M. D. Klinovitskii, and E. F. Anisimov, “Expert system for blast-furnace operators,” Metallurgist,54, No. 11–12, 730–798 (2011).

V. B. Trofimov, “Multi-structural instrument for identifying surface defects on rails,” Metallurgist,60, No. 3–4, 351–357 (2016).

V. B. Trofimov and S. M. Kulakov, “Generalized structure of an intelligent control system for technological objects and experience of its use,” Optoelectronics, Instrumentation and Data Processing,47, No. 3, 313–320 (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 64, No. 1, pp. 17–24, January, 2020.

Rights and permissions

About this article

Cite this article

Trofimov, V.B. Automated Expert Systems in Blast-Furnace Process Control. Metallurgist 64, 3–12 (2020). https://doi.org/10.1007/s11015-020-00961-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-020-00961-6