Abstract

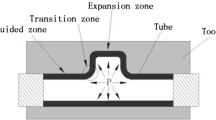

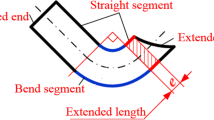

A novel differential lubrication method is proposed to improve the deformation behavior of L-shaped thin-walled with relative bending radius of 1 in push-bending process. The optimized tube blank is divided into four zones: inner deformation zone, inner guide zone, outer deformation zone and outer guide zone, which are lubricated with different lubricants. The differential lubrication and uniform lubrication methods for tube push-bending are first explored by means of simulation and experiments. The simulation results show that the differential lubrication method is more effective than the uniform lubrication method in suppressing wrinkles and expanding the process window. The outer thickness of tube increases with the increase of friction coefficient of the outer guide zone and the outer deformation zone, while the extension of tube end decreases with the increase of friction coefficient in any zone. Furthermore, with the proposed differential lubrication method, L-shpaed push-bending experiments of 5A02 aluminum alloy and 1Cr18Ni9 tube with relative bending radius of 1 were carried out to investigate this effect. The experimental results showed that the differential lubrication method effectively avoided wrinkling and the experimental results agreed well with the simulation results in wall thickness distribution and the extension of tube end.

Similar content being viewed by others

References

Zeng Y, Li Z (2002) Experimental research on the tube push-bending process. J Mater Process Technol 122(2):237–240

Shan-Ling H, Zhong-Qin L, Xiao-Yang L (2004) Process of push bending elbows and its parameters CAD system. Key Eng Mater 274-276:469–474

Oh IY, Han SW, Woo YY, Ra JH, Moon YH (2018) Tubular blank design to fabricate an elbow tube by a push-bending process. J Mater Process Technol 260:112–122

Baudin S, Ray P, Mac Donald BJ, Hashmi MSJ (2004) Development of a novel method of tube bending using finite element simulation. J Mater Process Technol 153-154:128–133

Montazeri S, Montazeri S, Gorji A, Gorji A, Bakhshi M, Bakhshi M (2016) A new method for compression bending of thin-walled tubes in hydro-bending process. Int J Adv Manuf Technol 85(1):557–571

Liu H, Zhang S, Song H, Shi G, Cheng M (2019) 3D FEM-DEM coupling analysis for granular-media-based thin-wall elbow tube push-bending process. Int J Mater Form 12(6):985–994

Guo Q, Ma F, Guo X, Tao J (2018) Influence of mandrel on the forming quality of bending L-shaped hollow parts. Int J Adv Manuf Technol 95(9):4513–4522

Sun Z, Chen S, Jing Y (2010) Numerical simulation of push-bending process of aluminum section profile. Adv Mater Res 97-101:90–95

Fiorentino A, Fiorentino A, Ceretti E, Ceretti E, Giardini C, Giardini C (2013) Tube hydroforming compression test for friction estimation—numerical inverse method, application, and analysis. Int J Adv Manuf Technol 64(5):695–705

Xu X, Wu K, Wu Y, Jie X, Fu C (2019) A novel lubrication method for hydroforming of thin-walled aluminum alloy T-shaped tube. Int J Adv Manuf Technol 102(5):2265–2273

Kim H, Sung JH, Sivakumar R, Altan T (2007) Evaluation of stamping lubricants using the deep drawing test. Int J Mach Tools Manuf 47(14):2120–2132

Abdelkefi A, Guermazi N, Boudeau N, Malécot P, Haddar N (2016) Effect of the lubrication between the tube and the die on the corner filling when hydroforming of different cross-sectional shapes. Int J Adv Manuf Technol 87(1):1169–1181

Zhao GY, Liu YL, Yang H (2007) Numerical simulation on influence of clearance and friction on wrinkling in bending of aluminum alloy rectangular tubes. Mater Sci Forum 546-549:833–838

Oliveira DA, Worswick MJ, Grantab R (2005) Effect of lubricant in mandrel-rotary draw tube bending of steel and aluminum. Can Metall Q 44(1):71–78

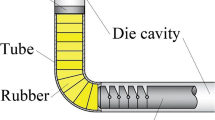

Xu X, Wu K, Wu Y, Fu C, Fan Y (2019) Push-bending method development of thin-walled tube with relative bending radius of 1 using sectional elastomers as mandrel. Int J Adv Manuf Technol 105(1–4):995–1008

Le HR, Sutcliffe MPF, Williams JA (2005) Friction and material transfer in micro-scale sliding contact between aluminium alloy and steel. Tribol Lett 18(1):99–104

Acknowledgments

The authors thank the financial supports from the National Natural Science Foundation of China with Grant (No.51405219 and No.51975267), the Key R&D Project in Jiangxi Province of China (No.20165ABC28002) and Project funded by Education Department of Jiangxi Province of China (No.GJJ180531).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, X., Fan, Y., Wu, Y. et al. A novel differential lubrication method for push-bending of L-shaped thin-walled tube with 1D bending radius. Int J Mater Form 14, 691–701 (2021). https://doi.org/10.1007/s12289-020-01563-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-020-01563-y