Abstract

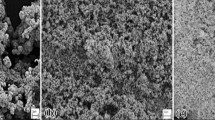

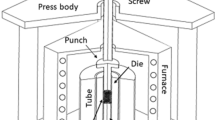

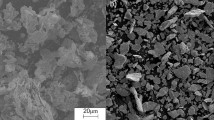

In the present work, x wt% B4C (x = 2, 4, 6, 8) and 2 wt% BN reinforced aluminum 6061 metal matrix hybrid composites were synthesized by mechanical milling for 10 h. The milled powders were consolidated by cold uniaxial compaction at various compression pressure (200–800 MPa) and then sintered at various temperatures (400–600 °C). Microstructural characterization of the milled powders and the fabricated composites were performed by X-ray diffraction, scanning electron microscope, and energy dispersive spectroscopy techniques. The effect of B4C/BN reinforcements on the densification of the milled powders was studied in terms of compressibility and sinterability. The mechanical properties, specifically the green compressive strength, and hardness of the composites were also investigated. The empirical relations formulated by Heckel, Panelli-Filho, and Ge were used to plot the compressibility curves of the developed composites to study the compressibility behavior of the milled powders. The densification co-efficient (K) of the powders and sinterability behavior of the composites decreased with an increase in B4C reinforcement. B4C particles prevented the grain growth by seizing the grain boundary, resulting in refinement of grains and enhancement in mechanical properties The maximum compressive strength of 249 MPa and hardness of 184 HV was observed for the sample Al6061–8 wt% B4C–2 wt% BN compressed at 800 MPa and sintered at 600 °C.

Graphic Abstract

Similar content being viewed by others

References

J.-J. Park, S.-M. Hong, M.-K. Lee, C.-K. Rhee, W.-H. Rhee, Enhancement in the microstructure and neutron shielding efficiency of sandwich type of 6061Al–B4C composite material via hot isostatic pressing. Nucl. Eng. Des. 282, 1–7 (6061Al)

X. Tan, F. Zeng, S. Wang, Z. Fei, X. Xiong, Effects of heat treatment on phase contents and mechanical properties of infiltrated B4C/2024Al composites. Trans. Nonferrous Metals Soc. China 24, 2359–2365 (2014)

R. Vintila, A. Charest, R.A.L. Drew, M. Brochu, Synthesis and consolidation via spark plasma sintering of nanostructured Al-5356/B4C composite. Mater. Sci. Eng. A 528, 4395–4407 (2011)

R.L. Deuis, C. Subramanian, J.M. Yellup, Dry sliding wear of aluminium composites—a review. Compos. Sci. Technol. 57, 415–435 (1997)

M.O. Bodunrin, K.K. Alaneme, L.H. Chown, Aluminium matrix hybrid composites: a review of reinforcement philosophies; mechanical, corrosion and tribological characteristics. J. Mater. Res. Technol. 4, 434–445 (2015)

J.M.D. Torralba, C.E. Da Costa, F. Velasco, P/M aluminum matrix composites: an overview. J. Mater. Process. Technol. 133, 203–206 (2003)

K. Halil, O. İsmail, D. Sibel, Ç. Ramazan, Wear and mechanical properties of Al6061/SiC/B4C hybrid composites produced with powder metallurgy. J. Mater. Res. Technol. 8, 5348–5361 (2019)

U.B. Gopal Krishna, K.V. Sreenivas Rao, B. Vasudeva, Effect of boron carbide reinforcement on aluminium matrix composites. Int. J. Metall. Mater. Sci. Eng. 3, 41–48 (2013)

H. Abdoli, E. Salahi, H. Farnoush, K. Pourazrang, Evolutions during synthesis of Al–AlN-nanostructured composite powder by mechanical alloying. J. Alloys Compd. 461, 166–172 (2008)

I. Ozdemir, S. Ahrens, S. Mücklich, B. Wielage, Nanocrystalline Al–Al2O3p and SiCp composites produced by high-energy ball milling. J. Mater. Process. Technol. 205, 111–118 (2008)

S. Samal, B. Satpati, D. Chaira, Production and dispersion stability of ultrafine Al–Cu alloy powder in base fluid. J. Alloys Compd. 504, S389–S394 (2010)

D. Jeyasimman, K. Sivaprasad, S. Sivasankaran, R. Ponalagusamy, R. Narayanasamy, V. Iyer, Microstructural observation, consolidation and mechanical behaviour of AA 6061 nanocomposites reinforced by γ-Al2O3 nanoparticles. Adv. Powder Technol. 26, 139–148 (2015)

M. Sameezadeh, M. Emamy, H. Farhangi, Effects of particulate reinforcement and heat treatment on the hardness and wear properties of AA 2024–MoSi2 nanocomposites. Mater. Des. 32, 2157–2164 (2011)

N. Hosseini, F. Karimzadeh, M.H. Abbasi, M.H. Enayati, Tribological properties of Al6061–Al2O3 nanocomposite prepared by milling and hot pressing. Mater. Des. 31, 4777–4785 (2010)

H. Arik, Effect of mechanical alloying process on mechanical properties of α-Si3N4 reinforced aluminum-based composite materials. Mater. Des. 29, 1856–1861 (2008)

T. Shanmugasundaram, M. Heilmaier, B.S. Murty, V.S. Sarma, On the Hall–Petch relationship in a nanostructured Al–Cu alloy. Mater. Sci. Eng. A 527, 7821–7825 (2010)

H. Kaftelen, M.L. Öveçoğlu, H. Henein, H. Çimenouğlu, ZrC particle reinforced Al–4 wt.% Cu alloy composites fabricated by mechanical alloying and vacuum hot pressing: microstructural evaluation and mechanical properties. Mater. Sci. Eng. A. 527, 5930–5938 (2010)

A. Pakdel, A. Witecka, G. Rydzek, D.N.A. Shri, V. Nicolosi, A comprehensive analysis of extrusion behavior, microstructural evolution, and mechanical properties of 6063 Al–B4C composites produced by semisolid stir casting. Mater. Sci. Eng. A 721, 28–37 (2018)

G. González-Doncel, O.D. Sherby, High temperature creep behavior of metal matrix aluminium–SiC composites. Acta Metall. Mater. 41, 2797–2805 (1993)

S. Poria, P. Sahoo, G. Sutradhar, Tribological characterization of stir-cast aluminium-TiB2 metal matrix composites. Silicon 8, 591–599 (2016)

C.S. Ramesh, R. Keshavamurthy, B.H. Channabasappa, A. Ahmed, Microstructure and mechanical properties of Ni–P coated Si3N4 reinforced Al6061 composites. Mater. Sci. Eng. A 502, 99–106 (2009)

P. Chandrasekhar, S. Chand, S. Singh, Investigation of dynamic effects during cold upset-forging of silicon carbide particulate reinforced aluminium metal matrix composite preforms. Mater. Today Proc. 5, 20201–20209 (2018)

A. Thuault, S. Marinel, E. Savary, R. Heuguet, S. Saunier, D. Goeuriot, D. Agrawal, Processing of reaction-bonded B4C–SiC composites in a single-mode microwave cavity. Ceram. Int. 39, 1215–1219 (2013)

V. Domnich, S. Reynaud, R.A. Haber, M. Chhowalla, Boron carbide: structure, properties, and stability under stress. J. Am. Ceram. Soc. 94, 3605–3628 (2011)

S. Chand, P. Chandrasekhar, R.K. Sarangi, R.K. Nayak, Influence of B4C particles on processing and strengthening mechanisms in aluminum metal matrix composites—a review. Mater. Today Proc. 18, 5356–5363 (2019)

H.S. Chen, W.X. Wang, Y.L. Li, J. Zhou, H.H. Nie, Q.C. Wu, The design, microstructure and mechanical properties of B4C/6061Al neutron absorber composites fabricated by SPS. Mater. Des. 94, 360–367 (2016)

A. Baradeswaran, A.E. Perumal, Study on mechanical and wear properties of Al 7075/Al2O3/graphite hybrid composites. Compos. Part B Eng. 56, 464–471 (2014)

R. Harichandran, N. Selvakumar, Microstructure and mechanical characterization of (B4C+ h-BN)/Al hybrid nanocomposites processed by ultrasound assisted casting. Int. J. Mech. Sci. 144, 814–826 (2018)

S. Mahathanabodee, T. Palathai, S. Raadnui, R. Tongsri, N. Sombatsompop, Effects of hexagonal boron nitride and sintering temperature on mechanical and tribological properties of SS316L/h-BN composites. Mater. Des. 46, 588–597 (2013)

S. Chand, P. Chandrasekhar, Influence of B4C/BN on solid particle erosion of Al6061 metal matrix hybrid composites fabricated through powder metallurgy technique. Ceram. Int. (2020). https://doi.org/10.1016/j.ceramint.2020.04.064

H.R. Hafizpour, A. Simchi, S. Parvizi, Analysis of the compaction behavior of Al–SiC nanocomposites using linear and non-linear compaction equations. Adv. Powder Technol. 21, 273–278 (2010)

S. Sivasankaran, K. Sivaprasad, R. Narayanasamy, V.K. Iyer, An investigation on flowability and compressibility of AA 6061100–xx wt.% TiO2 micro and nanocomposite powder prepared by blending and mechanical alloying. Powder Technol. 201, 70–82 (2010)

H. Abdoli, H. Farnoush, E. Salahi, K. Pourazrang, Study of the densification of a nanostructured composite powder: part 1: effect of compaction pressure and reinforcement addition. Mater. Sci. Eng. A 486, 580–584 (2008)

Z.R. Hesabi, H.R. Hafizpour, A. Simchi, An investigation on the compressibility of aluminum/nano-alumina composite powder prepared by blending and mechanical milling. Mater. Sci. Eng. A 454, 89–98 (2007)

H. Asgharzadeh, A. Simchi, H.S. Kim, A plastic-yield compaction model for nanostructured Al6063 alloy and Al6063/Al2O3 nanocomposite powder. Powder Technol. 211, 215–220 (2011)

D. Jeyasimman, S. Sivasankaran, K. Sivaprasad, R. Narayanasamy, R.S. Kambali, An investigation of the synthesis, consolidation and mechanical behaviour of Al 6061 nanocomposites reinforced by TiC via mechanical alloying. Mater. Des. 57, 394–404 (2014)

H. Alihosseini, K. Dehghani, J. Kamali, Microstructure characterization, mechanical properties, compressibility and sintering behavior of Al–B4C nanocomposite powders. Adv. Powder Technol. 28, 2126–2134 (2017)

Y.Z. Li, Q.Z. Wang, W.G. Wang, B.L. Xiao, Z.Y. Ma, Interfacial reaction mechanism between matrix and reinforcement in B4C/6061Al composites. Chem. Phys. Mater. (2015). https://doi.org/10.1016/j.matchemphys.2015.01.052

P. Zhang, Y. Li, W. Wang, Z. Gao, B. Wang, The design, fabrication and properties of B4C/Al neutron absorbers. J. Nucl. Mater. 437, 350–358 (2013)

K.D. Rogers, P. Daniels, An X-ray diffraction study of the effects of heat treatment on bone mineral microstructure. Biomaterials 23, 2577–2585 (2002)

M. Saleem, L. Fang, H.B. Ruan, F. Wu, Q.L. Huang, C.L. Xu, C.Y. Kong, Effect of zinc acetate concentration on the structural and optical properties of ZnO thin films deposited by sol–gel method. Int. J. Phys. Sci. 7, 2971–2979 (2012)

P. Bindu, S. Thomas, Estimation of lattice strain in ZnO nanoparticles: X-ray peak profile analysis. J. Theor. Appl. Phys. 8, 123–134 (2014)

G.K. Hall, G.K. Williamson, X-ray line broadening from filed aluminum and wolfram. Acta Metall. 1, 22 (1953)

J.B. Fogagnolo, E.M. Ruiz-Navas, M.H. Robert, J.M. Torralba, The effects of mechanical alloying on the compressibility of aluminium matrix composite powder. Mater. Sci. Eng. A 355, 50–55 (2003)

M. Azabou, M. Khitouni, A. Kolsi, Characterization of nanocrystalline Al-based alloy produced by mechanical milling followed by cold-pressing consolidation. Mater. Charact. 60, 499–505 (2009)

A.B. Van Groenou, Compaction of ceramic powders. Powder Technol. 28, 221–228 (1981)

R.W. Heckel, Density-pressure relationships in powder compaction. Trans. Metall. Soc. AIME 221, 671–675 (1961)

R. Panelli, F. Ambrozio Filho, A study of a new phenomenological compacting equation. Powder Technol. 114, 255–261 (2001)

R. Ge, A new equation for powder compaction. Powder Metall. Sci. Technol. 6, 20–24 (1995)

E. Trujillo-Vázquez, M.I. Pech-Canul, J.C. Guía-Tello, M.A. Pech-Canul, Surface chemistry modification for elimination of hydrophilic Al4C3 in B4C/Al composites. Mater. Des. 89, 94–101 (2016)

J. Ye, J. He, J.M. Schoenung, Cryomilling for the fabrication of a particulate B4C reinforced Al nanocomposite: part I. Effects of process conditions on structure. Metall. Mater. Trans. A 37, 3099–3109 (2006)

A. Alizadeh, E. Taheri-Nassaj, Wear behavior of nanostructured Al and Al–B4C nanocomposites produced by mechanical milling and hot extrusion. Tribol. Lett. 44, 59 (2011)

Acknowledgements

The authors would like to acknowledge Dr. S.K.S Parashar (Nano Synthesis Lab, School of Applied Science) and School of Mechanical Engineering, KIIT Deemed to be University, Bhubaneswar, India for their metal powder synthesis, composite fabrication and testing facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chand, S., Chandrasekhar, P., Roy, S. et al. Influence of Dispersoid Content on Compressibility, Sinterability and Mechanical Behaviour of B4C/BN Reinforced Al6061 Metal Matrix Hybrid Composites Fabricated via Mechanical Alloying. Met. Mater. Int. 27, 4841–4853 (2021). https://doi.org/10.1007/s12540-020-00739-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00739-0