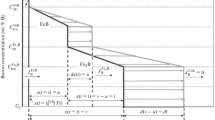

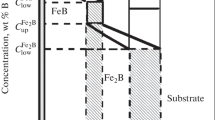

Diffusion of boron in FeB and Fe2B layers under solid boriding of steel AISI D2 (the Russian counterpart is Kh12MF) is simulated. Two approaches are used to assess the diffusion coefficients in solid-phase boriding, i.e., the concept of the mean value of diffusion coefficient in the FeB – Fe2B system and consideration of the growth kinetics of each of the two boride layers with the use of a system of conventional differential equations describing the partial chemical reactions by a parabolic law (the Dybkov method). The activation energies of boron diffusion in the FeB and Fe2B layers of steel AISI D2 are computed. The condition of extreme boriding is used to verify the two approaches experimentally. Comparative analysis of the computed and published data shows their good agreement.

Similar content being viewed by others

References

A. K. Sinha, “Boriding (boronizing) of steels,” J. Heat Treat., 4, 437 – 447 (1991).

X. Qiao, H. R. Stock, A. Kueper, and C. Jarms, “Effects of B(CH3O)3 content on a PACVD plasma-boriding process,” Surf. Coat. Technol., 131, 291 – 293 (2000).

A. Pertek and M. Kulka, “Characterization of complex (B + C) diffusion layers formed on chromium and nickel-based low-carbon steel,” Appl. Surf. Sci., 202, 252 – 260 (2002).

C. Martini, G. Palombarini, G. Poli, and D. Prandstraller, “Sliding and abrasive wear behavior of boride coatings,” Wear, 256, 608 – 613 (2004).

E. Filep and S. Farkas, “Kinetics of plasma-assisted boriding,” Surf. Coat. Technol., 199, 1 – 6 (2005).

M. Kulka, N. Makuch, A. Pertek, and L. Maldzinski, “Simulation on growth kinetics of boride layers formed on Fe during gas boriding in H2– BCl3 atmosphere,” J. Solid State Chem., 199, 196 – 203 (2014).

M. Keddam, M. Kulka, N. Makuch, et al., “A kinetic model for estimating the boron activation energies in the FeB and Fe2B layers during the gas-boriding on Armco iron: Effect of boride incubation times,” Appl. Surf. Sci., 298, 155 – 163 (2014).

A. Kaouka, O. Allaoui, and M. Keddam, “Properties of boride layer on borided SAE 1035 steel by molten salt,” Appl. Mech. Mater., 467, 116 – 121 (2014).

I. Campos, R. Torres, O. Bautista, et al., “Effect of boron paste thickness on the growth kinetics of polyphase boride coatings during the boriding process,” Appl. Surf. Sci., 252, 2396 – 2403 (2006).

M. Elias-Espinosa, M. Ortiz-Domingues, M. Keddam, et al., “Boriding kinetics and mechanical behavior of AISI O1 steel,” Surf. Eng., 31, 588 – 597 (2015).

K. G. Anthymidis, E. Stergioudis, and D. N. Tsipas, “Boriding in a fluidized bed reactor,” Mater. Lett., 51, 156 – 160 (2001).

Cabeo E. Rodriguez, G. Laudien, S. Biemer, et al., “Plasma-assisted boriding of industrial components in a pulsed d.c. glow discharge,” Surf. Coat. Technol., 116 – 119, 229 – 233 (1999).

M. Keddam, R. Chegroune, M. Kulka, et al., “Characterization, tribological and mechanical properties of plasma paste borided AISI 316 steel,” Trans. Indian Inst. Metals, 71, 79 – 90 (2018).

Ozhan Kayacan, Salim Sahin, and Filiz Tastan, “A study for boronizing process within not extensive thermostatistics,” Mathem. Comp. Appl., 15, 14 – 24 (2010).

I. Campos-Silva, N. López-Perrusquia, M. Ortiz-Domínguez, et al., “Characterization of boride layers formed at the surface of gray cast irons,” Kovove Mater., 47, 75 – 81 (2009).

M. Ortiz-Domínguez, M. A. Flores-Renteria, M. Keddam, et al., “Simulation of the growth kinetics of the Fe2B layers formed on gray cast irons during the powder-pack boriding process,” Mater. Technol., 48, 905 – 916 (2014).

M. Elias-Espinosa, M. Ortiz-Domínguez, M. Keddam, et al., “Growth kinetics of the Fe2B layers and adhesion on Armco iron substrate,” J. Mater. Eng. Perform., 23, 2943 – 2952 (2014).

M. Keddam, M. Ortiz-Domínguez, M. Elias-Espinosa et al., “Kinetic investigation and wear properties of Fe2B layers on AISI 12L14 steel,” Metall. Mater. Trans. A, 49, 1895 – 1907 (2018).

I. Campos-Silva, M. Flores-Jiménez, D. Bravo Bárcenas, et al., “Evolution of boride layers during a diffusion annealing process,” Surf. Coat. Technol., 309, 155 – 163 (2017).

I. Campos, R. Torres, G. Ramírez, et al., “Growth kinetics of iron boride layers: Dimensional analysis,” Appl. Surf. Sci., 252, 8662 – 8667 (2006).

C. I. Villa Velázquez-Mendoza, J. L. Rodriguez-Mendoza, V. Ibarra-Galvan, et al., “Effect of substrate roughness, time and temperature on the processing of iron boride coatings: experimental and statistical approaches,” Int. J. Surf. Sci. Eng., 8, 71 – 91 (2014).

I. Campos, M. Islas, G. Ramírez, C. Villa Velázquez, and C. Mota, “Growth kinetics of borided layers: Artificial neural network and least square approaches,” Appl. Surf. Eng., 253, 6226 – 6231 (2007).

I. Campos, M. Islas, E. González, et al., “Use of fuzzy logic for modeling the growth of Fe2B layers during boronizing,” Surf. Coat. Technol., 201, 2717 – 2723 (2006).

R. D. Ramdan, T. Takaki, and Y. Tomita, “Free energy problem for the simulations of the growth of Fe 2b phase using phasefield method,” Mater. Trans., 49, 625 – 2631 (2008).

R. Kouba, M. Keddam, and M. Kulka, “Modelling of the paste boriding process,” Surf. Eng., 31, 563 – 569 (2015).

I. Campos-Silva, R. Taledo-Rosas, H. D. Santos-Medina, and C. Lopez-Garcia, “Boride layers: growth kinetics and mechanical characterization,” in: Rafael Colas and George E. Totten (eds.), Encyclopedia of Iron, Steel and Their Alloys, Five-Volume Set (2015) (DOI: https://doi.org/10.1081/E-EISA-120052666).

Y. Ugaste, “On the interstitial phase growth kinetics at diffusional precipitation of metals,” in: Chemical and Thermal Treatment of Metals and Alloys, Belarus Technical Institute Press (1977), pp. 40 – 42.

V. I. Dybkov, “Effect of microstructure on the wear resistance of borided Fe – Cr alloys,” Int. J. Mater. Res., 104, 617 – 629 (2013).

J. Ratajski, “Model of growth kinetics of nitrided layer in the binary Fe – N system,” Zeitschrift für Metallkunde, 95, 823 – 828 (2004).

M. A. J. Somers and. E. J. Mittemeijer, “Layer-growth kinetics on gaseous nitriding of pure iron: Evaluation of diffusion coefficient for nitrogen in iron nitrides,” Metall. Mater. Trans. A, 26, 57 – 74 (1995).

L. G. Yu, X. J. Chen, A. K. Khor, and G. Sundararajan, “FeB/Fe2B phase transformation during SPS pack boriding: Boride layer growth kinetics,” Acta Mater., 53, 2361 – 2368 (2005).

M. Keddam, “Computer simulation of monolayer growth kinetics of Fe2B phase during the paste-boriding process: Influence of the phase thickness,” Appl. Surf. Sci, 253, 757 – 761 (2006).

M. Ortiz-Domínguez, M. Elias-Espinosa, M. Keddam, et al., “Growth kinetics and mechanical properties of Fe2B layers formed on AISI D2 steel,” Indian J. Eng. Mater. Sci., 22, 231 – 243 (2015).

L. G. Yu, K. A. Khor, and G. Sundararajan, “Boriding of mild steel using the spark plasma sintering (SPS) technique,” Surf. Coat. Technol., 157, 226 – 230 (2002).

G. Kartal, O. L. Eryilmaz, G. Krumdick, et al., “Kinetics of electrochemical boriding of low carbon steel,” Appl. Surf. Sci., 257, 6928 – 6934 (2011).

S. Sen, U. Sen, and C. Bindal, “An approach to kinetic study of borided steels,” Surf. Coat. Technol., 191, 274 – 285 (2005).

K. Genel, I. Ozbek, and C. Bindal, “Kinetics of boriding of AISI W1 steel,” Mater. Sci. Eng. A, 347, 311 – 314 (2003).

K. Genel, “Boriding kinetics of H13 steel,” Vacuum, 80, 451 – 457 (2006).

I. Campos-Silva, M. Ortiz-Domínguez, C. Tapia-Quintero, et al., “Kinetics and boron diffusion in the FeB/Fe2B layers formed at the surface of borided high-alloy steel,” J. Mater. Eng. Perform., 21, 1714 – 1723 (2012).

M. Keddam and M. Kulka, “A kinetic model for boriding kinetics of AISI D2 steel during the diffusion annealing process,” Protect. Met. Phys. Chem. Surf., 54, 282 – 290 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 12, pp. 13 – 20, December, 2019.

Rights and permissions

About this article

Cite this article

Keddam, M., Kulka, M. Simulation of Boriding Kinetics of AISI D2 Steel using Two Different Approaches. Met Sci Heat Treat 61, 756–763 (2020). https://doi.org/10.1007/s11041-020-00496-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-020-00496-2