Abstract

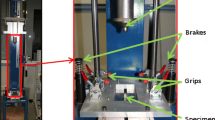

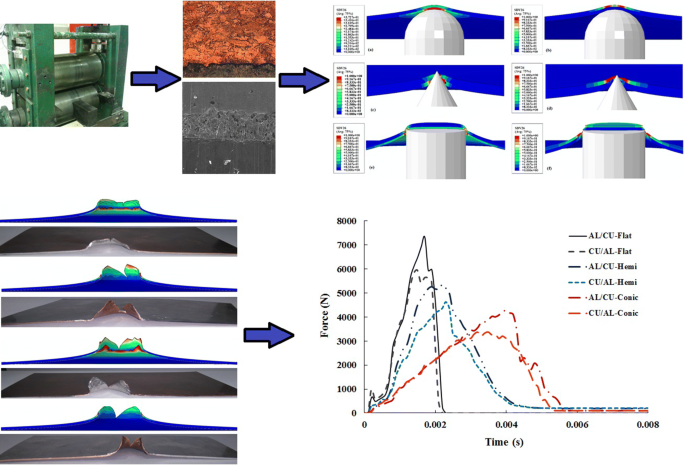

Cladded multilayer multi-material sheets are now extensively being used in different engineering fields. These sheets are well known for their excellent mechanical and functional properties, corrosion resistance and electrical conductivity. In the present study, low velocity impact of cladded two-layer sheets has been studied experimentally and numerically. The desired sheets were fabricated from aluminum AA1200 and copper (OFHC), and then, they were impacted at the impact energy of 45 J using two different impactor nose shapes. The effect of stacking sequence of the constituent layers on impact behavior of the cladded sheets was also investigated. Numerical modeling of the problem was carried out using finite element method where an energy-based rate-dependent damage model was developed and employed to model the behavior of the impacted sheets including damage initiation and evolution. The required rate constants were achieved using a direct experimental procedure as well as a calibration process via genetic algorithm. Also, for the numerical part of the research, one more impactor nose shape and two more impact energies were considered to be studied. Accuracy of both the finite element modeling and developed damage model was admitted by comparing the numerical results with experimental ones. Moreover, the achieved results prove the advantage of the Al/Cu sheet over the Cu/Al one in terms of both the energy absorption and impact strength.

Graphic abstract

Similar content being viewed by others

Abbreviations

- \( L_{\text{c}} \) :

-

Element characteristic length

- \( \xi \) :

-

Initiation parameter

- \( \xi_{\text{cr}} \) :

-

Critical value of initiation parameter

- \( D \) :

-

Damage variable

- E :

-

Young’s modulus

- e :

-

Deviatoric strain tensor

- G :

-

Shear moduli

- K :

-

Bulk moduli

- p :

-

Hydrostatic pressure

- R :

-

Radial growth of the yield surface

- r :

-

Material parameter

- \( \lambda \) :

-

Plastic consistency parameter for damage evolution

- s :

-

Deviatoric stress tensor

- \( C \) :

-

Stain rate dependency coefficient for yield stress

- \( Q \) :

-

Stain rate dependency coefficient for initiation parameter

- \( G_{\text{f}} \) :

-

Damage energy at failure

- V :

-

Volumetric strain

- \( {\text{SE}} \) :

-

Damage initiation strain energy release rate

- \( \varvec{\varepsilon} \) :

-

Strain tensor

- \( \dot{\varvec{\varepsilon }}^{\text{p}} \) :

-

Plastic strain tensor rate

- \( \dot{\varepsilon }_{\text{eq}}^{\text{p}} \) :

-

Equivalent plastic strain rate

- \( f \) :

-

Yield function

- \( \gamma \) :

-

Plastic consistency parameter for damage initiation

- v :

-

Poisson’s ratio

- \( \varvec{\sigma} \) :

-

Cauchy stress tensor

- \( m \) :

-

Stain rate dependency coefficient for damage energy

- \( \sigma_{\text{eq}} \) :

-

Equivalent stress

- \( \sigma_{Y}^{0} \) :

-

Initial yield stress

- \( \varphi \) :

-

Dissipation function

References

Backman ME, Goldsmith W (1978) The mechanics of penetration of projectiles into targets. Int J Eng Sci 16:1–99

Corbett GG, Reid SR, Johnson W (1996) Impact loading of plates and shells by free-flying projectiles: a review. Int J Impact Eng 18:141–230

Okajima K, Luk VK (1988) Penetration of 6061-T651 aluminum targets with rigid long rods. J Appl Mech 55:755–760

Ashby MF, Evans T, Fleck NA, Hutchinson JW, Wadley HN, Gibson LJ (2000) Metal foams: a design guide. Elsevier, Amsterdam

Zhao H, Elnasri I, Girard Y (2007) Perforation of aluminium foam core sandwich panels under impact loading—an experimental study. Int J Impact Eng 34:1246–1257

Hanssen AG, Girard Y, Olovsson L, Berstad T, Langseth M (2006) A numerical model for bird strike of aluminium foam-based sandwich panels. Int J Impact Eng 32:1127–1144

Hou W, Zhu F, Lu G, Fang DN (2010) Ballistic impact experiments of metallic sandwich panels with aluminum foam core. Int J Impact Eng 37:1045–1055

Flores-Johnson EA, Saleh M, Edwards L (2011) Ballistic performance of multi-layered metallic plates impacted by a 7.62-mm APM2 projectile. Int J Impact Eng 38:1022–1032

Ben-Dor G, Dubinsky A, Elperin T (2000) The optimum arrangement of the plates in a multi-layered shield. Int J Solids Struct 37:687–696

Ben-Dor G, Dubinsky A, Elperin T (1998) On the ballistic resistance of multi-layered targets with air gaps. Int J Solids Struct 35:3097–3103

Teng X, Dey S, Børvik T, Wierzbicki T (2007) Protection performance of double-layered metal shields against projectile. J Mech Mater Struct 2:1309–1329

Abdullah MR, Cantwell WJ (2006) The impact resistance of polypropylene-based fiber–metal laminates. Compos Sci Technol 66:1682–1693

Caprino G, Spataro G, Del Luongo S (2004) Low-velocity impact behavior of fibreglass–aluminum laminates. Compos Part A Appl Sci Manuf 35:605–616

Payeganeh GH, Ghasemi FA, Malekzadeh K (2010) Dynamic response of fiber–metal laminates (FMLs) subjected to low-velocity impact. Thin Walled Struct 48:62–70

Kurşun A, Şenel M, Enginsoy HM, Bayraktar E (2016) Effect of impactor shapes on the low velocity impact damage of sandwich composite plate: experimental study and modeling. Compos Part B Eng 86:143–151

Liu C, Zhang YX, Ye L (2017) High velocity impact responses of sandwich panels with metal fibre laminate skins and aluminium foam core. Int J Impact Eng 100:139–153

Bonora N, Gentile D, Pirondi A, Newaz G (2005) Ductile damage evolution under triaxial state of stress: theory and experiments. Int J Plast 21:981–1007

Lemaitre J (1984) How to use damage mechanics. Nucl Eng Des 80:233–245

Børvik T, Hopperstad OS, Berstad T, Langseth M (2001) A computational model of viscoplasticity and ductile damage for impact and penetration. Eur J Mech 20:685–712

Lemaitre J (1992) A course on damage mechanics. Springer, Berlin

Lemaitre J (1985) A continuous damage mechanics model for ductile fracture. Trans ASME J Eng Mater Technol 107:83–89

Mashayekhi M, Ziaei-Rad S, Parvizian J, Niklewicz J, Hadavinia H (2007) Ductile crack growth based on damage criterion: experimental and numerical studies. Mech Mater 39:623–636

Saeedi MR, Morovvati MR, Alizadeh-Vaghasloo Y (2018) Experimental and numerical study of mode-I and mixed-mode fracture of ductile U-notched functionally graded materials. Int J Mech Sci 144:324–340

Mashayekhi M, Ziaei-Rad S, Parvizian J, Nikbin K, Hadavinia H (2005) Numerical analysis of damage evolution in ductile solids. Struct Integr Durab 1:67–82

Fagerholt E, Grytten F, Gihleengen BE, Langseth M, Børvik T (2010) Continuous out-of-plane deformation measurements of AA5083-H116 plates subjected to low-velocity impact loading. Int J Mech Sci 52:689–705

Grytten F, Børvik T, Hopperstad OS, Langseth M (2009) Low velocity perforation of AA5083-H116 aluminium plates. Int J Impact Eng 36:597–610

Banerjee A, Dhar S, Acharyya S, Datta D, Nayak N (2015) Determination of Johnson cook material and failure model constants and numerical modelling of Charpy impact test of armour steel. Mater Sci Eng A 640:200–209

Morovvati MR, Mollaei-Dariani B, Asadian-Ardakani MH (2010) A theoretical, numerical, and experimental investigation of plastic wrinkling of circular two-layer sheet metal in the deep drawing. J Mater Process Technol 210:1738–1747

Morovvati MR, Mollaei-Dariani B (2017) The effect of annealing on the formability of aluminum 1200 after accumulative roll bonding. J Manuf Process 30:241–254

Morovvati MR, Fatemi A, Sadighi M (2011) Experimental and finite element investigation on wrinkling of circular single layer and two-layer sheet metals in deep drawing process. Int J Adv Manuf Technol 54:113–121

Morovvati MR, Mollaei-Dariani B, Haddadzadeh M (2010) Initial blank optimization in multilayer deep drawing process using GONNS. ASME J Manuf Sci Eng 132:10–14

Pourmoghadam MN, Esfahani RS, Morovvati MR, Rizi BN (2013) Bifurcation analysis of plastic wrinkling formation for anisotropic laminated sheets (AA2024–Polyamide–AA2024). Comput Mater Sci 77:35–43

ASTM E8-04 (2004) Standard test methods for tension testing of metallic materials. ASTM International, West Conshohocken

Abaqus US, E. U. Manuals Version 6.3 (2002) Hibbitt. Karlsson & Sorensen Inc, Rhode Island

Acknowledgement

The corresponding author would like to express his gratitude to Iran National Science Foundation (INSF) for supporting this research under Grant Number 96011030.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A

1.1 Plastic corrector scheme

Step 1. Calculation of the trial values for the strain increment of \( \Delta \varepsilon \):

Step 2. Check the yield condition:

And then check:

IF\( f^{\text{trial}} \le 0 \)THEN (Elastic region)

Update \( \left( \cdot \right)_{n + 1} = \left( \cdot \right)^{\text{trial}} \)RETURN

ELSE (Plastic region)

Step 3. Obtain \( \Delta \gamma \):

Step 4. Update the required parameters:

ENDIF

RETURN

Appendix B

2.1 Algorithm of damage evolution

Step 1. Calculation of the trial values for the strain increment of \( \Delta \varepsilon \):

Step 2. Check the yield condition:

And then check:

IF\( f^{\text{trial}} \le 0 \)THEN (no evolution of damage parameter)

Update \( \left( \cdot \right)_{n + 1} = \left( \cdot \right)^{\text{trial}} \)RETURN

ELSE (evolution of damage parameter)

Step 3. Obtain \( \Delta \lambda \):

Step 4. Calculate the equivalent plastic strain

Step 5. Update the damage variable using the new equivalent plastic strain:

Step 6. Update the required parameters:

ENDIF

RETURN

Rights and permissions

About this article

Cite this article

Saeedi, M.R., Morovvati, M.R. & Mollaei-Dariani, B. Experimental and numerical investigation of impact resistance of aluminum–copper cladded sheets using an energy-based damage model. J Braz. Soc. Mech. Sci. Eng. 42, 310 (2020). https://doi.org/10.1007/s40430-020-02397-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02397-0