Abstract

A simple microwave method was employed to prepare silica-doped mesoporous zirconia nanoparticles, SiO2/ZrO2 (SiZr) catalysts under various Si amount and then characterized by X-ray diffraction, nitrogen adsorption–desorption analyses, Fourier-transform infrared, electron spin resonance, ultraviolet–visible diffuse reflectance spectroscopy and photoluminescence analyses. The lower amount of Si fully stabilized the ZrO2 in the tetragonal phase (t-ZrO2), but the higher amount of Si occupied oxygen vacancies (OV) in the SiZr lattice to disrupt the catalysts with introduce low content of monoclinic phase. The catalyst activity towards on photodegradation of 2-chlorophenol (2-CP) was ranked in the following order: 1SiZr (92%) > TiO2 (73%) > 2SiZr (67%) > 3SiZr (64%) > 4SiZr (56%) > ZrO2 (51%). This result demonstrated that 1SiZr gave the highest degradation percentage of 10 mg L−1 2-CP at pH 5 using 0.375 g L−1 catalyst under visible light irradation within 4 h. The highest photoactivity of 1SiZr is due to the larger surface area and crystallite size, which resulted in a good surface contact with light and thus accelerated the photocatalytic activity. Additionally, the highest amount of OV possesed by 1 SiZr effectively suppressed the electron–hole recombination by acting as an electron acceptors, which consequently affected the t-ZrO2 stabilization as well as the catalytic activity. The kinetics of photocatalytic degradation of 2-CP correlated with pseudo-first order model, with the surface reaction as the controlling step. The photogenerated hole was the most active species as confirmed by effect of scavenger study. The 1SiZr maintained the photocatalytic activities after five runs and has a great capability in degrading of various phenols derivatives, indicating its potential use in the phenol-based wastewater treatment.

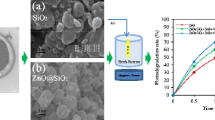

Graphic Abstract

Similar content being viewed by others

References

Azami MS, Jalil AA, Hitam CNC, Hassan NS, Mamat CR, Adnan RH, Chanlek N (2020) Appl Surf Sci 512:145744

Igbinosa EO, Odjadjare EE, Chigor VN, Igbinosa IH, Emoghene AO, Ekhaise FO, Igiehon NO, Idemudia OG (2013) Sci World J 1:1–11

Jusoh R, Jalil AA, Triwahyono S, Idris A, Haron S, Sapawe N, Jaafar NF, Jusoh NWC (2014) Appl Catal A 469:33–44

Sharotri N, Sud D (2016) Desalin Water Treat 57:8776–8788

Peng S, Tang Z, Jiang W, Wu D, Hong S, Xing B (2017) Sci Total Environ 581:550–558

Duan X, Zhao C, Liu W, Zhao X, Chang L (2017) Electrochim Acta 240:424–436

Jaafar NF, Jalil AA, Triwahyono S, Shamsuddin N (2015) RSC Adv 5:90991–91000

Solís-Casados DA, Martínez-Peña J, Hernández-López S, Escobar-Alarcón L (2020) Top Catal 1–11.

Melchor-Lagar V, Ramos-Ramirez E, Morales-Perez A, Rangel-Vazquez I, Angel GD (2020) J Photoch Photobio A 389:112251

Reddy CV, Reddy IN, Akkinepally B, Harish VVN, Reddy KR, Jaesool S (2019) Ceram Int 45:15298–15306

Hassan NS, Jalil AA, Triwahyono S, Hitam CNC, Rahman AFA, Khusnun NF, Prasetyoko D (2018) J Taiwan Inst Chem Eng 82:322–330

Basahel SN, Ali TT, Mokhtar M, Narasimharao K (2015) Nanoscale Res Lett 10:73–86

Gorban O, Synyakina S, Volkova G, Gorban S, Konstantiova T, Lyubchik S (2015) J Solid State Chem 232:249–255

Sudrajat H, Babel S, Sakai H, Takizawa S (2016) J Environ Manag 165:224–234

Agorku ES, Kuvarega AT, Mamba BB, Pandey AC, Mishra AK (2015) J Rare Earths 33:498–506

Gurushantha K, Anantharaju KS, Nagabhushana H, Sharma SC, Vidya YS, Shivakumara C, Anilkumar MR (2015) J Mol Catal A Chem 397:36–47

Renuka L, Anantharaju KS, Sharma SC, Nagaswarupa HP, Prashantha SC, Nagabhushana H, Vidya YS (2016) J Alloys Compd 672:609–622

Poungchan G, Ksapabutr B, Panapoy M (2016) Mater Des 89:137–145

Carevic MV, Abazovic ND, Novakovic TB, Pavlovic VB, Comor MI (2016) Appl Catal B 195:112–120

Hassan NS, Jalil AA, Triwahyono S, Khusnun NF, Izan SM, Kidam K, Johari A (2018) J Mol Liq 261:423–430

Vignesh K, Suganthi A, Min B, Kang M (2015) Appl Surface Sci 324:652–661

Fakhri A, Behrouz S, Tyagi I, Agarwal S, Gupta VK (2016) J Mol Liq 216:342–346

Dwivedi R, Maurya A, Verma A, Prasad R, Bartwal KS (2011) J Alloys Compd 509:6848–6851

Adamski A, Jakubus P, Sojka Z (2007) Solid State Phenom 128:89–96

Gauna MR, Conconi MS, Gomez S, Suarez G, Aglieeti EF, Rendtorff NM (2015) Ceram-Silik 59:318–325

Li P, Chen I (1994) J Am Ceram Soc 77:1289–1295

Hitam CNC, Jalil AA, Triwahyono S, Ahmad A, Jaafar NF, Salamun N, Ghazali Z (2016) RSC Adv 6:76259–76268

Khusnun NF, Jalil AA, Triwahyono S, Hitam CNC, Hassan NS, Jamian F, Hartanto D (2018) Powder Technol 327:170–178

Karim AH, Jalil AA, Triwahyono S, Kamarudin NHN, Ripin A (2014) J Colloid Interface Sci 421:93–102

Hassan NS, Jalil AA, Khusnun NF, Ali MW, Haron S (2019) J Alloys Compd 789:221–230

Jusoh NWC, Jalil AA, Triwahyono S, Karim AH, Salleh NF, Annuar NHR, Jaafar NF, Firmansyah ML, Mukti RR, Ali MW (2015) Appl Surf Sci 330:10–19

Patel A, Singh S (2016) J Taiwan Inst Chem Eng 64:306–313

Hassan NS, Roslani NJ, Jalil AA, Triwahyono S, Salleh NF, Jaafar NF (2015) Mal J Fund Appl Sci 11:148–151

Maheswari AU, Kumar SS, Sivakumar M (2014) Ceram Int 40:6561–6568

Wang H, Yao X, Sui G, Yin L, Wang L (2015) J Mater Sci Technol 31:164–170

Kouva S, Honkala K, Leffertsac L, Kanervo J (2015) Catal. Sci. Technol 5:3473–3490

Siddiquey IA, Furusawa T, Sato M, Bahadur NM, Uddin MN, Suzuki N (2013) Ceram Int 7:1755–1760

Gionco C, Paganini MC, Giamello E, Burgess R, Valentin CD, Pacchioni G (2013) Chem Mater 25:2243–2253

Zhang J, Gao Y, Jia X, Wang J, Chen Z, Xu Y (2018) Sol Energy Mater Sol Cells 182:113–120

Fauzi AA, Jalil AA, Mohamed M, Triwahyono S, Jusoh NWC, Rahman AFA, Tanaka H (2018) J Environ Manag 227:34–43

Hitam CNC, Jalil AA, Triwahyono S, Rahman AFA, Hassan NS, Khusnun NF, Ahmad A (2018) Fuel 216:407–417

Rahman AFA, Jalil AA, Triwahyono S, Ripin A, Aziz FFA, Fatah NAA, Hassan NS (2017) J Clean Prod 143:948–959

Nandiyanto ABD, Zaen R, Oktiani R (2017) Arab J Chem 13:1283–1296

Jaafar NF, Jalil AA, Triwahyono S (2017) Appl Surf Sci 392:1068–1077

Elsalamony RA, Mahmoud SA (2017) Arab J Chem 10:194–205

Khusnun NF, Jalil AA, Triwahyono S, Jusoh NWC, Johari A, Kidam K (2016) Phys Chem Chem Phys 18:12323–12331

Singh AK, Nakate UT (2014) Sci World J 1–7.

Zhou X, Lai C, Huang D, Zeng G, Chen L, Qin L, Xu P, Cheng M, Huang C, Zhang C, Zhou C (2018) J Hazard Mater 346:113–123

Aziz FFA, Jalil AA, Triwahyono S, Mohamed M (2018) Appl Surf Sci 455:84–95

Acknowledgements

The authors are grateful for the financial support by the Universiti Teknologi Malaysia through Professional Development Research University Grant (No. 04E73), Fundamental Research Grant Scheme from Ministry of Higher Education Malaysia (Grant No. FRGS/1/2019/STG07/UTM/01/1 -5F192) and Research University Grant from Universiti Teknologi Malaysia (Grant No. 08G92).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that there are no known conflicts of interest associated with this publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hassan, N.S., Jalil, A.A., Aziz, F.F.A. et al. Tailoring the Silica Amount in Stabilizing the Tetragonal Phase of Zirconia for Enhanced Photodegradation of 2-Chlorophenol. Top Catal 63, 1145–1156 (2020). https://doi.org/10.1007/s11244-020-01274-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-020-01274-3