Abstract

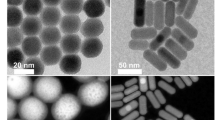

Static charges on optical anti-counterfeiting membranes may lead to materials structural changes, dust stain aggravation, and misreading of optical information. Incorporating conductive particles is a common way to transfer accumulative charges, but the key issue is how to achieve high dispersion and effective distribution of particles. According to the strategy of assembly-induced structural colors, cellulose nanocrystals (CNCs) were employed as a solid emulsifier to stabilize hydrophobic carbon nanoparticles (CNPs) in aqueous media; subsequently, by solvent-evaporation-modulated co-assembly under a condition of 30 °C and 20 RH%, the binary suspensions containing 2 wt% CNC and CNPs with the equivalent concentration relative to CNC ranged from 1:40 to 1:10 were used to prepare antistatic composite membranes. Surface chemistry regulation of CNCs was applied to optimize the dispersibility of CNPs and the orientation of assembled CNC arrays, and the hydrophilic CNCs were more favorable for dispersion and assembly of binary suspension systems. Meanwhile, one-dimension carbon nanotube (CNT) and zero-dimension carbon black (CB) were found to show better dispersibility than two-dimension graphene, which was verified by a semiquantitative theoretical study. Moreover, the stable binary systems of CNT/CNC and CB/CNC were chosen for co-assembly as membranes, and the uniaxial orientation could be optimized as the full-width of 9.8° at half-maximum deviation angle while the surface resistivity could also drop down to 3.42 × 102 Ω·cm·cm−1. The structural color character of such paper-homology and antistatic-integrated membranes contributes to optical information hiding-and-reading, and shows great potential as optical mark recognition materials for electrostatic discharge protective packaging and anti-counterfeiting applications.

Similar content being viewed by others

References

Chen, L.; Lai, C.; Marchewka, R.; Berry, R. M.; Tam, K. C. Use of CdS quantum dot-functionalized cellulose nanocrystal films for anti-counterfeiting applications. Nanoscale 2016, 8, 13288–13296.

Chu, L.; Zhang, X.; Niu, W.; Wu, S.; Ma, W.; Tang, B.; Zhang, S. Hollow silica opals/cellulose acetate nanocomposite films with structural colors for anti-counterfeiting of banknotes. J. Mater. Chem. C 2019, 7, 7411–7417.

Zhang, J.; Zhao, L.; Liu, Y.; Li, M.; Li, G.; Meng, X. Two luminescent transition-metal-organic frameworks with a predesigned ligand as highly sensitive and selective iron(III) sensors. New J. Chem. 2018, 42, 6839–6847.

Yao, K.; Meng, Q.; Bulone, V.; Zhou, Q. Flexible and responsive chiral nematic cellulose nanocrystal/poly(ethylene glycol) composite films with uniform and tunable structural color. Adv. Mater. 2017, 29, 1701323.

Khan, M. K.; Bsoul, A.; Walus, K.; Hamad, W. Y.; MacLachlan, M. J. Photonic patterns printed in chiral nematic mesoporous resins. Angew. Chem. Int. Ed. 2015, 54, 4304–4308.

Gan, L.; Feng, N.; Liu, S.; Zheng, S.; Li, Z.; Huang, J. Assembly-induced emission of cellulose nanocrystals for hiding information. Part. Part. Syst. Char. 2019, 36, 1800412.

Qu, D.; Zheng, H.; Jiang, H.; Xu, Y.; Tang, Z. Chiral photonic cellulose films enabling mechano/chemo responsive selective reflection of circularly polarized light. Adv. Opt. Mater. 2019, 7, 1801395.

Nandi, S.; Guha, P. A review on preparation and properties of cellulose nanocrystal-incorporated natural biopolymer. J. Package. Technol. Res. 2018, 2, 149–166.

Giese, M.; Blusch, L. K.; Khan, M. K.; MacLachlan, M. J. Functional materials from cellulose-derived liquid-crystal templates. Angew. Chem. Int. Ed. 2015, 54, 2888–2910.

Liu, Y.; Schutz, C.; Salazar-Alvarez, G.; Bergström, L. Assembly, gelation, and helicoidal consolidation of nanocellulose dispersions. Langmuir 2019, 35, 3600–3606.

Liu, D.; Wang, S.; Ma, Z.; Tian, D.; Gu, M.; Lin, F. Structure-color mechanism of iridescent cellulose nanocrystal films. RSC Adv. 2014, 4, 39322–39331.

Khandelwal, M.; Windle, A. H. Self-assembly of bacterial and tunicate cellulose nanowhiskers. Polymer 2013, 54, 5199–5206.

Lizundia, E.; Nguyen, T. D.; Vilas, J. L.; Hamad, W. Y.; MacLachlan, M. J. Chiroptical luminescent nanostructured cellulose films. Mater. Chem. Front. 2017, 1, 979–987.

Razalli, R. L.; Abdi, M. M.; Tahir, P. M.; Moradbak, A.; Sulaiman, Y.; Heng, L. Y. Polyaniline-modified nanocellulose prepared from Semantan bamboo by chemical polymerization: preparation and characterization. RSC Adv. 2017, 7, 25191–25198.

Wu, C. S.; Liao, H. T. Characterization and antistatic behavior of SiO2-functionalized multiwalled carbon nanotube/poly(trimethylene terephthalate) composites. J. Polym. Res. 2013, 20, 253.

Qu, D.; Zhang, F.; Gao, H.; Wang, Q.; Bai, Y.; Liu, H. Studies on isosorbide-enhanced biodegradable poly(ethylene succinate). Chem. Res. Chinese U. 2019, 35, 345–352.

Querejeta-Fernandez, A.; Chauve, G.; Methot, M.; Bouchard, J.; Kumacheva, E. Chiral plasmonic films formed by gold nanorods and cellulose nanocrystals. J. Am. Chem. Soc. 0014, 136, 4788–4793.

Sun, S. J.; Wei, Fan, J.; Lin, C. Y. The electrical conduction variation in stained carbon nanotubes. Physica E 2012, 44, 803–807.

Pei, S.; Cheng, H. M. The reduction of graphene oxide. Carbon 2012, 50, 3210–3228.

Wu, X.; Lu, C.; Zhang, X.; Zhou, Z. Conductive natural rubber/carbon black nanocomposites via cellulose nanowhisker templated assembly: tailored hierarchical structure leading to synergistic property enhancements. J. Mater. Chem. A 2015, 3, 13317–13323.

Wu, X.; Han, Y.; Zhang, X.; Zhou, Z.; Lu, C. Large-area compliant, low-cost, and versatile pressure-sensing platform based on microcrack-designed carbon black@polyurethane sponge for human-machine interfacing. Adv. Funct. Mater. 2016, 26, 6246–6256.

Wu, X.; Lu, C.; Han, Y.; Zhou, Z.; Yuan, G.; Zhang, X. Cellulose nanowhisker modulated 3D hierarchical conductive structure of carbon black/natural rubber nanocomposites for liquid and strain sensing application. Compos. Sci. Technol. 2016, 124, 44–51.

Montes, S.; Carrasco, P. M.; Ruiz, V.; Cabañero, G.; Grande, H. J.; Labidi, J.; Odriozola, I. Synergistic reinforcement of poly(vinyl alcohol) nanocomposites with cellulose nanocrystal-stabilized graphene. Compos. Sci. Technol. 2015, 117, 26–31.

Zhu, L.; Zhou, X.; Liu, Y.; Fu, Q. Highly sensitive, ultrastretchable strain sensors prepared by pumping hybrid fillers of carbon nanotubes/cellulose nanocrystal into electrospun polyurethane membranes. ACS Appl. Mater. Interfaces 2019, 11, 12968–12977.

Zhao, W.; Li, X.; Gao, S.; Feng, Y.; Huang, J. Understanding mechanical characteristics of cellulose nanocrystals reinforced PHEMA nanocomposite hydrogel: in aqueous cyclic test. Cellulose 2017, 24, 2095–2110.

Yu, H. Y.; Qin, Z. Y.; Liu, L.; Yang, X. G.; Zhou, Y.; Yao, J. M. Comparison of the reinforcing effects for cellulose nanocrystals obtained by sulfuric and hydrochloric acid hydrolysis on the mechanical and thermal properties of bacterial polyester. Compos. Sci. Technol. 2013, 87, 22–28.

Gan, L.; Liao, J.; Lin, N.; Hu, C.; Wang, H.; Huang, J. Focus on gradientwise control of the surface acetylation of cellulose nanocrystals to optimize mechanical reinforcement for hydrophobic polyester-based nanocomposites. ACS Omega 2017, 2, 4725–4736.

Habibi, Y.; Chanzy, H.; Vignon, M. R. TEMPO-mediated surface oxidation of cellulose whiskers. Cellulose 2006, 13, 679–687.

Gomez-Bujedo, S.; Fleury, E.; Vignon, M. R. Preparation of cellouronic acids and partially acetylated cellouronic acids by TEMPO/NaClO oxidation of water-soluble cellulose acetate. Biomacromolecules 2008, 5, 565–571.

Fraschini, C.; Chauve, G.; Bouchard, J. TEMPO-mediated surface oxidation of cellulose nanocrystals (CNCs). Cellulose 2017, 24, 2775–2790.

Lin, N.; Dufresne, A. Surface chemistry, morphological analysis and properties of cellulose nanocrystals with gradiented sulfation degrees. Nanoscale 2014, 6, 5384–5693.

Zhou, L.; Zhu, D.; Zhang, S.; Pan, B. A settling curve modeling method for quantitative description of the dispersion stability of carbon nanotubes in aquatic environments. J. Environ. Sci. 2015, 29, 1–10.

Glotzer, S. C.; Horsch, M. A.; Iacovella, C. R.; Zhang, Z.; Chan, E. R.; Zhang, X. Self-assembly of anisotropic tethered nanoparticle shape amphiphiles. Curr. Opin. Colloid In. 2005, 10, 287–295.

McClements, J.; Shaver, M. P.; Sefiane, K.; Koutsos, V. Morphology of poly(styrene-co-butadiene) random copolymer thin films and nanostructures on a graphite surface. Langmuir 2018, 34, 7784–7796.

Lin, N.; Huang, J.; Chang, P. R.; Feng, J.; Yu, J. Surface acetylation of cellulose nanocrystal and its reinforcing function in poly(lactic acid). Carbohyd. Polym. 2011, 83, 1834–1842.

Lin, N.; Bruzzese, C.; Dufresne, A. TEMPO-oxidized nanocellulose participating as crosslinking aid for alginate-based sponges. ACS Appl. Mater. Interfaces 2012, 4, 4948–4959.

Molnes, S. N.; Paso, K. G.; Strand, S.; Syverud, K. The effects of pH, time and temperature on the stability and viscosity of cellulose nanocrystal (CNC) dispersions: implications for use in enhanced oil recovery. Cellulose 2017, 24, 4479–4491.

Liu, S.; Chen, Y.; Liu, C.; Gan, L.; Ma, X.; Huang, J. Polydopamine-coated cellulose nanocrystals as an active ingredient in poly(vinyl alcohol) films towards intensifying packaging application potential. Cellulose 2019, 26, 9599–9612.

Kiprono, S. J.; Ullah, M. W.; Yang, G. Encapsulation of E. coli in biomimetic and Fe3O4-doped hydrogel: structural and viability analyses. Appl. Microbiol. Biot. 2018, 102, 933–944.

Figarol, A.; Pourchez, J.; Boudard, D.; Forest, V.; Akono, C.; Tulliani, J. M.; Lecompte, J. P.; Cottier, M.; Bernache-Assollant, D.; Grosseau, P. In vitro toxicity of carbon nanotubes, nano-graphite and carbon black, similar impacts of acid functionalization. Toxicol. in Vitro 2015, 30, 476–485.

Kumar, S. M. S.; Herrero, J. S.; Irusta, S.; Scott, K. The effect of pretreatment of Vulcan XC-72R carbon on morphology and electrochemical oxygen reduction kinetics of supported Pd nano-particle in acidic electrolyte. J. Electroanal. Chem. 2010, 647, 211–221.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 51973175 and 51603171), the Project for Chongqing University Innovation Research Group (No. CXQT19008), the Chongqing Talent Plan for Innovation and Entrepreneurship Demonstration Team (No. CQYC201903243), and the Key Laboratory of Polymeric Composite & Functional Materials of Ministry of Education (No. PCFM201605).

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Information

10118_2020_2414_MOESM1_ESM.pdf

Antistatic Structural Color and Photoluminescent Membranes from Co-Assembling Cellulose Nanocrystals and Carbon Nanoparticles for Anti-counterfeiting

Rights and permissions

About this article

Cite this article

Liu, SY., Gong, YB., Ma, S. et al. Antistatic Structural Color and Photoluminescent Membranes from Co-assembling Cellulose Nanocrystals and Carbon Nanomaterials for Anti-counterfeiting. Chin J Polym Sci 38, 1061–1071 (2020). https://doi.org/10.1007/s10118-020-2414-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-020-2414-x