Abstract

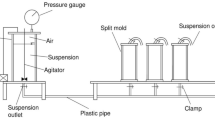

The rheological properties of sands conditioned with different conditioners and injection ratios were examined. The conditioned sands were prepared with a 40% and 60% volume injection ratio of a bentonite slurry or a carboxymethyl cellulose (CMC) solution. The experiment results show that the tested bentonite-conditioned sand exhibits the characteristics of a Herschel-Bulkley fluid at shear rates in the range of 0–10 s−1 while the CMC-conditioned sand conforms to the power law model. The flow curves of all of the samples show a marked shear-thinning behavior. They also indicated that the existence of a yield stress (τ0) depends only on the rheological behavior of the conditioner and that the yield stress (τ0 if present) and the plastic viscosity (μp) increase with an increase in the volumetric concentration of the sand. Furthermore, to characterize the thixotropy of the conditioned sand, experiments were carried out by using three loading histories with shear rate accelerations of 0.1, 0.2 and 0.4 s−1/s. In the measured results, the thixotropy of the conditioned sand is heavily dependent on the recent flow history. Based on the experimental data, a simple thixotropic prediction model was developed to analyze and predict the transient flow curves of bentonite-conditioned sands.

Similar content being viewed by others

References

Benchabane A, Bekkour K (2008) Rheological properties of carboxymethyl cellulose (CMC) solutions. Colloid and Polymer Science 286(10):1173–1180, DOI: 10.1007/s00396-008-1882-2

Benyounes K, Benmounah A (2015) Rheological and electrokinetic characterization of bentonite particles in aqueous phase in presence of KC1. Particulate Science and Technology 34(2016):39–44, DOI: 10.1080/02726351.2015.1042563

Benyounes K, Mellak A, Benchabane A (2010) The effect of carboxymethylcellulose and xanthan on the rheology of bentonite suspensions. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 32(17):1634–1643, DOI: 10.1080/15567030902842244

Borio L, Peila D (2010) Study of the permeability of foam conditioneel soils with laboratory tests. American Journal of Environmental Sciences 6(4):365–370, DOI: 10.3844/ajessp.2010.365.370

Cheng DC, Evans F (1965) Phenomenological characterization of the rheological behaviour of inelastic reversible thixotropic and antithixotropic fluids. British Journal of Applied Physics 16(11):1599–1617, DOI: 10.1088/0508-3443/16/11/301

Cordeiro GC, de Alvarenga LMSC, Rocha CAA (2016) Rheological and mechanical properties of concrete containing crushed granite fine aggregate. Construction and Building Materials 111:766-773, DOI:10.1016/j.conbuildmat.2016.02.178

Coussot P, Nguyen QD, Huynh HT, Bonn D (2002a) Viscosity bifurcation in thixotropic, yielding fluids. Journal of Rheology 46(3):573–589, DOI: 10.1122/1.1459447

Coussot P, Raynaud JS, Bertrand F, Moucheront P, Lesueur D (2020b) Coexistence of liquid and solid phases in flowing soft-glassy materials. Physical Review Letters 88(21):218301, DOI: 10.1103/ PhysRevLett.88.218301

Dunstan DE, Hill EK, Wei Y (2004) Direct measurement of polymer segment orientation and distortion in shear: Semi-dilute solution behavior. Polymer 45(4):1261–1266, DOI: 10.1016/j.polymer.2003. 12.018

Galli M, Thewes M (2019) Rheological characterisation of foam-conditioned sands in EPB tunneling. International Journal of Civil Engineering 17(1):145–160, DOI: 10.1007/s40999-018-0316-x

Goh R, Leong YK, Lehane B (2011) Bentonite slurries-zeta potential, yield stress, adsorbed additive and time-dependent behaviour. Rheologica Acta 50(1):29–38, DOI: 10.1007/s00397-010-0498-x

Hong E, Herbert CM, Yeneneh AM, Sen TK (2016) Rheological characteristics of mixed kaolin-sand slurry, impacts of pH, temperature, solid concentration and kaolin-sand mixing ratio. International Journal of Environmental Science and Technology 13(11):2629–2638, DOI: 10.1007/s13762-016-1090-4

Huang S, Wang S, Xu C, Shi Y, Ye F (2019) Effect of grain gradation on the permeability characteristics of coarse-grained soil conditioned with foam for EPB shield tunneling. KSCE Journal of Civil Engineering 23(11):4662–4674, DOI: 10.1007/s12205-019-0717-7

Jeong SW, Locat J, Leroueil S, Malet JP (2010) Rheological properties of fine-grained sediment: The roles of texture and mineralogy. Canadian Geotechnical Journal 47(10):1085–1100, DOI: 10.1139/ T10-012

Jin DL, Yuan DJ, Li XQ Zheng HT (2018) Analysis of the settlement of an existing tunnel induced by shield tunneling underneath. Tunnelling and Underground Space Technology 81:209–220, DOI: 10.1016/j.tust.2018.06.035

Kaci A, Chaouche M, Andréani PA (2011) Influence of bentonite clay on the rheological behaviour of fresh mortars. Cement and Concrete Research 41(4):373–379, DOI: 10.1016/j.cemconres.2011.01.002

Kim TH, Kim BK, Lee KH, Lee IM (2019) Soil conditioning of weathered granite soil used for EPB shield TBM: A laboratory scale study. KSCE Journal of Civil Engineering 23(4):1829–1838, DOI: 10.1007/s12205-019-1484-l

Kök MV, Batmaz T, Gücüyener IH (2000) Rheological behavior of bentonite suspensions. Petroleum Science and Technology 18(5-6):519–536, DOI: 10.1080/10916460008949858

Lizarraga MS, Vicin DDP, Gonzalez R, Rubiolo A, Santiago LG (2006) Rheological behaviour of whey protein concentrate and λ-carrageenan aqueous mixtures. Food Hydrocolloids 20(5):740–748, DOI: 10.1016/j.foodhyd.2005.07.007

Merrill J, Voisin L, Montenegro V, Ihle CF, McFarlane A (2017) Slurry rheology prediction based on hyperspectral characterization models for minerals quantification. Minerals Engineering 109:126–134, DOI: 10.1016/j.mineng.2017.03.009

Merritt AS, Mair RJ (2006) Mechanics of tunnelling machine screw conveyors: Model tests. Geotechnique 56(9):605–615, DOI: 10.1680/geot.2006.56.9.605

Mesboua N, Benyounes K, Benmounah A (2018) Study of the impact of bentonite on the physico-mechanical and flow properties of cement grout. Cogent Engineering 5:1446252, DOI: 10.1080/23311916.2018.1446252

Min F, Song H, Zhang N (2018) Experimental study on fluid properties of slurry and its influence on slurry infiltration in sand stratum. Applied Clay Science 161:64-69, DOI: 10.1016/j.clay.2018.03.028

Mori L, Mooney M, Cha M (2018) Characterizing the influence of stress on foam conditioned sand for EPB tunneling. Tunnelling and Underground Space Technology 71:454–465, DOI: 10.1016/j.tust.2017.09.018

Peila D, Oggeri C, Borio L (2009) Using the slump test to assess the behavior of conditioned soil for EPB tunneling. Environmental & Engineering Geoscience 15(3):167–174

Pinho FT, Whitelaw JH (1990) Flow of non-Newtonian fluids in a pipe. Journal of Non-newtonian Fluid Mechanics 34(2):129–144, DOI: 10.1016/0377-0257(90)80015-r

Rivas J, Jimenez A, Videra O, Gégout P, Vallon F, Pegon J (2009) Reducing the environmental impact of tunnel boring (OSCAR). In: Technology innovation in underground construction. CRC Press/Balkema, Leiden, Netherlands, 239–259

Roussel N (2006) A thixotropy model for fresh fluid concretes: Theory, validation and applications. Cement and Concrete Research 36(10):1797–1806, DOI: 10.1016/j.cemconres.2006.05.025

Roussel N, Le Roy R, Coussot P (2004) Thixotropy modelling at local and macroscopic scales. Journal of non-newtonian fluid mechanics 117(2-3):85–95, DOI: 10.1016/j.jnnfin.2004.01.001

Scotto SA, Pellegrino AM, Evangelista A (2010) Experimental study on the rheological behaviour of debris flow. Natural Hazards and Earth System Science 10(12):2507–2514, DOI: 10.5194/nhess-10-2507-2010

Thewes M, Budach C (2010) Soil conditioning with foam during EPB tunnelling. Geomechanics and Tunnelling 3(3):256–267, DOI: 10.1002/geot.201000023

Vinai R, Oggeri C, Peila D (2008) Soil conditioning of sand for EPB applications: A laboratory research. Tunnelling and Underground Space Technology 23(3):308–317, DOI: 10.1016/j.tust.2007.04.010

Xu J, Huhe A (2016) Rheological study ofmudflows at Lianyungang in China. International Journal of Sediment Research 31(1):71–78, DOI: 10.1016/j.ijsrc.2014.06.002

Yang Y, Li XQ, Li XC (2018) Shear strength and compression coefficient for conditioned sand subjected to earth chamber stress levels. Advances in Materials Science and Engineering 2018(2):1–11, DOI: 10.1155/2018/1759151

Yang WY, Yu GL, Tan SK, Wang HK (2014) Rheological properties of dense natural cohesive sediments subject to shear loadings. International Journal of Sediment Research 29(4):454–470, DOI: 10.1016/S1001-6279(14)60059-7

Zumsteg R, Plötze M, Puzrin AM (2012) Effect of soil conditioners on the pressure and rate-dependent shear strength of different clays. Journal of Geotechnical and Geoenvironmental Engineering 138(9):1138–1146, DOI: 10.1061/(ASCE)GT1943-5606.0000681

Acknowledgements

The authors would like to acknowledge the National Basic Research Program of China (“973” Program, 2015CB057802) and the National Natural Science Foundation of China (No. 51978040) for supporting this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Y., Li, XG. & Su, WL. Experimental Investigation on Rheological Behaviors of Bentonite- and CMC-Conditioned Sands. KSCE J Civ Eng 24, 1914–1923 (2020). https://doi.org/10.1007/s12205-020-2035-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12205-020-2035-5