Abstract

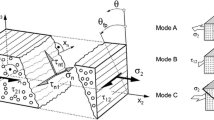

A constitutive damage model is proposed in order to investigate the crushing response of \(0^{\circ }\) plies composite laminates, using a VUMAT subroutine implemented in ABAQUS/Explicit. This damage model predicts five failure mechanisms commonly observed in unidirectional carbon fibre-reinforced composite structures: fibre failure in tension, fibre failure in compression, matrix cracking in tension, matrix cracking in compression and in-plane shear failure. Its formulation is based on an energy framework which combines stress-based fracture mechanics and damage mechanics approaches within a unified way, enabling the prediction of the five failure mechanisms aforementioned in terms of damage initiation and damage propagation. In this work, a new strategy is also implemented to remove fully damage elements in order to ensure numerical stability and avoid element distortion problems. An experimental test campaign is proposed for verification of the numerical models. Preliminary results have shown a fairly good correlation between numerical predictions and experimental results for wedge-shaped tip composite laminates.

Similar content being viewed by others

References

O’Rourke BP (1990) The uses of composite materials in the design and manufacture of Formula 1 racing cars. Des Compos Mater. https://doi.org/10.1243/PIME_PROC_1990_204_131_02

Savage GM (2001) Exploiting the fracture properties of fibre reinforced composites to enhance the survivability of formula one racing cars. Anales de Mecánica de la Fractura 18:274–282

Savage G, Bomphray I, Oxley M (2004) Exploiting the fracture properties of carbon fibre composites to design lightweight energy absorbing structures. Eng Fail Anal 11:677–694. https://doi.org/10.1016/j.engfailanal.2004.01.001

Federation Internationale De L’Automobile (2019) F1 technical regulation. [S.I.]

Mellor AN (2002) Impact testing in formula one. Int J Crashworthiness 7:475–486. https://doi.org/10.1533/cras.2002.0231

Caliskan AG (2002) Design and analysis of composite impact structures for formula one using explicit FEA technique. In: Proceedings of the 2002 SAE motorsport engineering conference and exhibition, vol 111, pp 2360–2367

Bisagni C, Di Pietro G, Fraschini L, Terletti D (2005) Progressive crushing of fiber-reinforced composite struc-tural componentes of a formula one racing car. Compos Struct 68:491–503. https://doi.org/10.1016/j.compstruct.2004.04.015

Heimbs S, Strobl F, Middendorf S, Garner B, Eddington B, Key J (2009) Crash simulation of an F1 racing car front impact structure. In: 7th European LS-Dyna conference. DYNAmore GmbH. [S.I.: s.n]

Thornton PH (1979) Energy absorption in composite structures. J Compos Mater 13:247–262. https://doi.org/10.1177/002199837901300308

Hull D (1991) A unified approach to progressive crushing of fibre-reinforced composite tubes. Compos Sci Technol 40:377–421. https://doi.org/10.1016/0266-3538(91)90031-J

Farley GF, Jones RM (1992) Crushing characteristics of continuous fiber-reinforced composite tubes. J Compos Mater 26:37–50. https://doi.org/10.1177/002199839202600103

Mamalis A, Manolakos D, Demosthenous G, Ioannidis M (1996) Analysis of failure mechanisms observed in axial collapse of thin-walled circular fibreglass composite tubes. Thin Walled Struct 24:335–352. https://doi.org/10.1016/0263-8231(95)00042-9

Chiu LN, Falzon BG, Ruan D, Xu S, Thomson RS, Chen B, Yan W (2015) Crush response of composite cylinder under quasi-static and dynamic loading. Compos Struct 131:90–98. https://doi.org/10.1016/j.compstruct.2015.04.057

Huang J, Wang X (2010) On a new crush trigger for energy absorption of composite tubes. Int J Crashworthiness 15:625–634. https://doi.org/10.1080/13588265.2010.484194

Feraboli P (2008) Development of a corrugated test specimen for composite materials energy absorption. J Compos Mater 42:229–256. https://doi.org/10.1177/0021998307086202

Israr HA, Rivallant S, Barrau JJ (2013) Experimental investigation on mean crushing stress characterization of carbon-epoxy plies under compressive crushing mode. Compos Struct 96:57–364. https://doi.org/10.1016/j.compstruct.2012.09.022

Xiao X, McGregor C, Vaziri R, Poursartip A (2009) Progress in braided composite tube crush simulation. Int J Impact Eng 36:711–719. https://doi.org/10.1016/j.ijimpeng.2008.09.006

Sokolinsky VS, Indermuehle KC, Hurtado JA (2011) Numerical simulation of the crushing process of a corrugated composite plate. Compos A Appl Sci Manuf 45:1119–1126. https://doi.org/10.1016/j.compositesa.2011.04.017

Israr HA, Rivallant S, Bouvet C, Barrau JJ (2014) Finite element simulation of \(0^{\circ }/90^{\circ }\) CFRP laminated plates subjected to crushing using free-face-crushing concept. Compos A Appl Sci Manuf 62:16–25. https://doi.org/10.1016/j.compositesa.2014.03.014

Chiu LN, Falzon BG, Boman R, Chen B, Yan W (2015) Finite element modelling of composite structures under crushing load. Compos Struct 131:215–228. https://doi.org/10.1016/j.compstruct.2015.05.008

Tan W, Falzon BG, Price M (2015) Predicting the crushing behaviour of composite material using high-fidelity finite element modelling. Int J Crashworthiness 20:60–77. https://doi.org/10.1080/13588265.2014.972122

Benzeggagh ML, Kenane M (1996) Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Compos Sci Technol 56:439–449. https://doi.org/10.1016/0266-3538(96)00005-X

Sales RCM, Endo BLRD, Donadon MV (2016) Influence of temperature on interlaminar fracture toughness of a carbon fibre-epoxy composite material. Adv Mater Res 1135:35–51. https://doi.org/10.4028/www.scientific.net/AMR.1135.35

Endo BLRD (2014) Caracterização da tenacidade à fratura interlaminar de um material compósito de fibra de carbono-epoxi considerando influência termomecânica. Dissertação de Mestrado, Instituto Tecnológico de Aeronáutica (ITA)

Czabaj MW, Ratcliffe JG (2013) Comparison of intralaminar and interlaminar mode I fracture toughnesses of a unidirectional IM7/8552 carbon/epoxy composite. Compos Sci Technol 89:15–23. https://doi.org/10.1016/j.compscitech.2013.09.008

Donadon MV, De Almeida SFM, Arbelo MA, De Faria AR (2009) A three-dimensional ply failure model for composite structures. Int J Aerosp Eng. https://doi.org/10.1155/2009/486063

Donadon MV, Iannucci L, Falzon BG, Hodgkinson JM, de Almeida SFM (2008) A progressive failure model for composite laminates subjected to low velocity impact damage. Comput Struct 86:1232–1252. https://doi.org/10.1016/j.compstruc.2007.11.004

Dassault-Systems. ABAQUS documentation 6.14. SIMULIA

Acknowledgements

The authors acknowledge the financial support received for this work from CAPES (Coordination for the Improvement of Higher Level—or Education—Personnel, Finance Code 001), CNPq (National Research Council) Grant 301053/2016-2 and FINEP/CHAPTER II, Grant 0109020700.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Oliveira, S.A.C., Donadon, M.V. & Arbelo, M.A. Crushing simulation using an energy-based damage model. J Braz. Soc. Mech. Sci. Eng. 42, 296 (2020). https://doi.org/10.1007/s40430-020-02383-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02383-6