Abstract

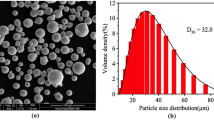

In this study, the effects of the single and multiple productions of samples by additive manufacturing on residual stress and displacement (distortions) were investigated. The samples were manufactured by Selective Laser Melting (SLM) machine using Ti6Al4V powders. Each time a different number (1, 5 and 13 samples) of cubic shaped samples were produced on the building platform. During the process, samples were observed with a thermal camera first, in order to understand the relationship amongst the residual stress, displacement and temperature gradients. Then, displacement values were measured experimentally with Coordinate Measurement Machine (CMM) device. Next, both displacement and residual stresses were calculated via Finite Element Analysis (FEA) method. Finally, residual stresses and displacement equations were determined by genetic expressional programming (GEP) using the results and data obtained from the tests and FEA. According to the results, the regression values of residual stress and displacement equation were found to be 0.96% and 0.88%, respectively. As the number of manufactured samples on the same platform increased, temperatures and irregular temperature distribution were increased.

Similar content being viewed by others

References

Bhavar V, Kattire P, Patil V, Khot S, Gujar K, Singh R (2017) A review on powder bed fusion technology of metal additive manufacturing. In Additive manufacturing handbook (pp. 251-253). CRC Press. https://doi.org/10.1201/9781315119106-15

Sing SL, An J, Yeong WY, Wiria FE (2016) Laser and electron-beam powder-bed additive manufacturing of metallic implants: a review on processes, materials and designs. J Orthop Res 34(3):369–385. https://doi.org/10.1002/jor.23075

Irrinki H, Dexter M, Barmore B, Enneti R, Pasebani S, Badwe S, Atre SV (2016) Effects of powder attributes and laser powder bed fusion (L-PBF) process conditions on the densification and mechanical properties of 17-4 PH stainless steel. Jom 68(3):860–868. https://doi.org/10.1007/s11837-015-1770-4

Galarraga H, Lados DA, Dehoff RR, Kirka MM, Nandwana P (2016) Effects of the microstructure and porosity on properties of Ti-6Al-4V ELI alloy fabricated by electron beam melting (EBM). Addit Manufact 10:47–57. https://doi.org/10.1016/j.addma.2016.02.003

Brandl E, Heckenberger U, Holzinger V, Buchbinder D (2012) Additive manufactured AlSi10Mg samples using Selective Laser Melting (SLM): microstructure, high cycle fatigue, and fracture behavior. Mater Des 34:159–169. https://doi.org/10.1016/j.matdes.2011.07.067

Fette M, Sander P, Wulfsberg J, Zierk H, Herrmann A, Stoess N (2015) Optimized and cost-efficient compression molds manufactured by selective laser melting for the production of thermoset Fiber reinforced plastic aircraft components. Procedia CIRP 35:25–30. https://doi.org/10.1016/j.procir.2015.08.082

Andani MT, Dehghani R, Karamooz-Ravari MR, Mirzaeifar R, Ni J (2017) Spatter formation in selective laser melting process using multi-laser technology. Mater Des 131:460–469. https://doi.org/10.1016/j.matdes.2017.06.040

Delgado J, Ciurana J, Rodríguez CA (2012) Influence of process parameters on part quality and mechanical properties for DMLS and SLM with iron-based materials. Int J Adv Manuf Technol 60(5–8):601–610. https://doi.org/10.1007/s00170-011-3643-5

Cherry JA, Davies HM, Mehmood S, Lavery NP, Brown SGR, Sienz J (2015) Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int J Adv Manuf Technol 76(5–8):869–879. https://doi.org/10.1007/s00170-014-6297-2

Olakanmi EO, Cochrane RF, Dalgarno KW (2015) A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: processing, microstructure, and properties. Prog Mater Sci 74:401–477. https://doi.org/10.1016/j.pmatsci.2015.03.002

Darvish K, Chen ZW, Pasang T (2016) Reducing lack of fusion during selective laser melting of CoCrMo alloy: effect of laser power on geometrical features of tracks. Mater Des 112:357–366. https://doi.org/10.1016/j.matdes.2016.09.086

Dadbakhsh S, Speirs M, Kruth JP, Schrooten J, Luyten J, Van Humbeeck J (2014) Effect of SLM parameters on transformation temperatures of shape memory nickel titanium parts. Adv Eng Mater 16(9):1140–1146. https://doi.org/10.1002/adem.201300558

Mercelis P, Kruth JP (2006) Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp J 12(5):254–265. https://doi.org/10.1108/13552540610707013

Yadroitsev I, Yadroitsava I (2015) Evaluation of residual stress in stainless steel 316L and Ti6Al4V samples produced by selective laser melting. Virtual Phys Prototyp 10(2):67–76. https://doi.org/10.1080/17452759.2015.1026045

Li Y, Zhou K, Tan P, Tor SB, Chua CK, Leong KF (2018) Modeling temperature and residual stress fields in selective laser melting. Int J Mech Sci 136:24–35. https://doi.org/10.1557/PROC-758-LL1.8

Everton SK, Hirsch M, Stravroulakis P, Leach RK, Clare AT (2016) Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater Des 95:431–445. https://doi.org/10.1016/j.matdes.2016.01.099

Rodriguez E, Mireles J, Terrazas CA, Espalin D, Perez MA, Wicker RB (2015) Approximation of absolute surface temperature measurements of powder bed fusion additive manufacturing technology using in situ infrared thermography. Addit Manufact 5:31–39. https://doi.org/10.1016/j.addma.2014.12.001

Thompson A, Maskery I, Leach RK (2016) X-ray computed tomography for additive manufacturing: a review. Meas Sci Technol 27(7):072001. https://doi.org/10.1088/0957-0233/27/7/072001

Spears TG, Gold SA (2016) In-process sensing in selective laser melting (SLM) additive manufacturing. Integr Mater Manuf Innov 5(1):16–40. https://doi.org/10.1186/s40192-016-0045-4

Lane B, Moylan S, Whitenton EP, Ma L (2016) Thermographic measurements of the commercial laser powder bed fusion process at NIST. Rapid Prototyp J 22(5):778–787. https://doi.org/10.1108/RPJ-11-2015-0161

Khorasani A, Gibson I, Goldberg M, Littlefair G (2017) On the role of different annealing heat treatments on mechanical properties and microstructure of selective laser melted and conventional wrought Ti-6Al-4V. Rapid Prototyp J 23(2):295–304. https://doi.org/10.1108/RPJ-02-2016-0022

Simonelli M, Tse YY, Tuck C (2014) Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti–6Al–4V. Mater Sci Eng A 616:1–11. https://doi.org/10.1016/j.msea.2014.07.086

Parry L, Ashcroft IA, Wildman RD (2016) Understanding the effect of laser scan strategy on residual stress in selective laser melting through thermo-mechanical simulation. Addit Manufact 12:1. https://doi.org/10.1016/j.addma.2016.05.014

Yan Z, Liu W, Tang Z, Liu X, Zhang N, Li M, Zhang H (2018) Review on thermal analysis in laser-based additive manufacturing. Opt Laser Technol 106:427–441. https://doi.org/10.1016/j.optlastec.2018.04.034

Li C, Fu CH, Guo YB, Fang FZ (2016) A multiscale modeling approach for fast prediction of part distortion in selective laser melting. J Mater Process Technol 229:703–712. https://doi.org/10.1016/j.jmatprotec.2015.10.022

Lott P, Schleifenbaum H, Meiners W, Wissenbach K, Hinke C, Bültmann J (2011) Design of an optical system for the in situ process monitoring of selective laser melting (SLM). Phys Procedia 12:683–690. https://doi.org/10.1016/j.phpro.2011.03.085

Du Y, You X, Qiao F, Guo L, Liu Z (2019) A model for predicting the temperature field during selective laser melting. Results Phys 12:52–60. https://doi.org/10.1016/j.rinp.2018.11.031

Ali H, Ghadbeigi H, Mumtaz K (2018) Residual stress development in selective laser-melted Ti6Al4V: a parametric thermal modelling approach. Int J Adv Manuf Technol 97(5–8):2621–2633. https://doi.org/10.1007/s00170-018-2104-9

Kayacan MC, Delikanlı YE, Duman B, Özsoy K (2018) Ti6Al4v toz alaşımı kullanılarak SLS ile üretilen geçişli (değişken) gözenekli numunelerin mekanik özelliklerinin incelenmesi. Gazi Üniversitesi Mühendislik-Mimarlık Fakültesi Dergisi 33(1). https://doi.org/10.17341/gazimmfd.406786

EOS GBMH, EOS Titanium Ti64 material datasheet, https://cdn.eos.info/a4eeb73865d54434/5926811b3739/Ti-Ti64_9011-0014_9011-0039_M290_Material_data_sheet_11-17_en.pdf Accessed: 15.01.2020

Fluke. The principles of noncontact temperature measurement. support.fluke.com/raytek-sales/Download/Asset/ Accessed:25 December 2018

Farshidianfar MH, Khajepour A, Gerlich AP (2016) Effect of real-time cooling rate on microstructure in laser additive manufacturing. J Mater Process Technol 231:468–478. https://doi.org/10.1016/j.jmatprotec.2016.01.017

Masoomi M, Thompson SM, Shamsaei N (2017) Laser powder bed fusion of Ti-6Al-4V parts: thermal modeling and mechanical implications. Int J Mach Tools Manuf 118:73–90. https://doi.org/10.1016/j.ijmachtools.2017.04.007

Gouge M, Michaleris P, Denlinger E, Irwin J (2018) The finite element method for the thermo-mechanical modeling of additive manufacturing processes. In Thermo-mechanical modeling of additive manufacturing (pp. 19-38). Butterworth-Heinemann. https://doi.org/10.1016/B978-0-12-811820-7.00003-3

Olleak A, Xi Z (2018) Finite element modeling of the selective laser melting process for Ti-6Al-4V. Solid freeform fabrication 2018: Proceedings of the 29th Annual International, 1710-1720

Yakout M, Elbestawi MA, Veldhuis SC, Nangle-Smith S (2019) Influence of thermal properties on residual stresses in SLM of aerospace alloys. Rapid Prototyp J. https://doi.org/10.1108/RPJ-03-2019-0065

Tan P, Shen F, Li B, Zhou K (2019) A thermo-metallurgical-mechanical model for selective laser melting of Ti6Al4V. Mater Des 168:107642. https://doi.org/10.1016/j.matdes.2019.107642

Ferreira C (2002) Gene expression programming in problem solving. In: Soft computing and industry. Springer, London, pp 635–653. https://doi.org/10.1007/978-1-4471-0123-9_54

Maamoun A, Xue Y, Elbestawi M, Veldhuis S (2018) Effect of selective laser melting process parameters on the quality of al alloy parts: powder characterization, density, surface roughness, and dimensional accuracy. Materials 11(12):2343. https://doi.org/10.3390/ma11122343

Atzeni E, Salmi A (2012) Economics of additive manufacturing for end-usable metal parts. Int J Adv Manuf Technol 62(9–12):1147–1155. https://doi.org/10.1007/s00170-011-3878-1

Masoomi M, Thompson S M, Shamsaei N, Elwany A, Bian L (2015) An experimental-numerical investigation of heat transfer during selective laser melting. In 26th International Solid Freeform Fabrication Symposium (pp. 1-14). https://doi.org/10.13140/RG.2.1.2325.0645

Vora P, Mumtaz K, Todd I, Hopkinson N (2015) AlSi12 in-situ alloy formation and residual stress reduction using anchorless selective laser melting. Addit Manufact 7:12–19. https://doi.org/10.1016/j.addma.2015.06.003

Gu D, He B (2016) Finite element simulation and experimental investigation of residual stresses in selective laser melted Ti–Ni shape memory alloy. Comput Mater Sci 117:221–232. https://doi.org/10.1016/j.commatsci.2016.01.044

Kayacan MY, Özsoy K, Duman B, Yilmaz N, Kayacan MC (2019) A study on elimination of failures resulting from layering and internal stresses in Powder Bed Fusion (PBF) additive manufacturing. Mater Manuf Process 34(13):1467–1475. https://doi.org/10.1080/10426914.2019.1655151

Acknowledgements

Authors thanks to Autodesk for significant supports by supplying Netfabb Simulation Utility.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yılmaz, N., Kayacan, M.Y. Effect of single and multiple parts manufacturing on temperature-induced residual stress problems in SLM. Int J Mater Form 14, 407–419 (2021). https://doi.org/10.1007/s12289-020-01560-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-020-01560-1