Abstract

To improve our understanding of prehistoric casting methods and materials, simulations for copper arsenic (As-Cu) alloys with up to 15 wt.% As were calculated. Cooling curves and the secondary dendritic arm spacings (SDAS) for the alloy were plotted and calculated, respectively, under non-steady-state conditions with a time-stepping procedure for prehistoric mold materials (e.g., quartz sand, sandstone, terracotta, and steatite). The cooling and microstructure of the alloy was also simulated in iron molds for immediate comparison with as-cast microstructure. The microstructure and SDAS of the as-cast alloys were studied and measured in polished samples with a metallographic microscope. The purpose of this research was to improve our ability to retroactively evaluate the influence of mold materials on as-cast microstructures and determine their materials. This article focuses on As-Cu alloy microstructure and SDAS values, and also discusses the phenomenon of “inverse segregation” and its relation to cooling rate and As concentration.

Similar content being viewed by others

Abbreviations

- A :

-

Mold metal interface (m2)

- α :

-

Overall heat transmission coefficient (W m−2 K−1)

- c :

-

Specific heat of the mold (J kg−1 K−1)

- c m :

-

Specific heat of the metal (J kg−1 K−1)

- c 0 :

-

Alloy concentration (wt.%)

- c l :

-

Concentration of the liquid phase (wt.%)

- D :

-

Diffusion coefficient (m2 s−1)

- h :

-

Heat transfer coefficient (W m−2 K−1)

- k :

-

Thermal conductivity of the mold (W m−1 K−1)

- k 0 :

-

Partition coefficient

- f s :

-

Mass fraction of solid phase

- m :

-

Slope of the liquidus line (K wt.%−1)

- n :

-

Time-step sequence (10−3 s)

- t :

-

Time (s)

- t f :

-

Local solidification time (s)

- T :

-

Temperature of the metal (K)

- T 0 :

-

Ambient temperature of the mold (K)

- v :

-

Volume of casting (m3)

- ΔT :

-

Solidification interval (K)

- ΔHf :

-

Latent heat of fusion (J mol−1)

- ρ :

-

Density of the mold (kg m−3)

- ρ m :

-

Density of the metal (kg m−3)

- Γ :

-

Gibbs–Thomson coefficient (K m)

- λ :

-

Secondary dendritic arm spacing (µm)

References

M. Mödlinger and B. Sabatini, J. Archaeol. Sci. 74, 60 (2016). https://doi.org/10.1016/j.jas.2016.08.005.

M. Mödlinger, D. Macció, A. Cziegler, H. Schnideritsch, and B. Sabatini, Metall. Mater. Trans. B 49, 2505 (2018). https://doi.org/10.1007/s11663-018-1322-8.

H. Lechtman, J. Field Archaeol. 23, 477 (1996). https://doi.org/10.2307/530550.

H. Lechtman and S. Klein, J. Archaeol. Sci. 26, 497 (1999).

T. Rehren, L. Boscher, and E. Pernicka, J. Archaeol. Sci. 39, 1717 (2012).

E.C. Rollason, Metallurgy for Engineers (London: Edward Arnold & Co, 1949).

E.G. Garrison, A History of Engineering and Technology. Artful Methods, 2nd ed. (Boca Raton: CRC Press, 1998).

J. Günter, K.J.A. Kundig, and J.A. Konrad, Copper: Its Trade, Manufacture, Use, and Environmental Status (Materials Park: International Copper Association, 1999).

A. Nayar, The Metals Databook (New York: McGraw-Hill Companies, 1997).

A. Giumla-Mair, Surf. Eng. 24, 110 (2008).

F. Pereira, R.J.C. Silva, A. Soares, M. Araújo, and J. Cardoso, Mater. Manuf. Process. 21, 1 (2016).

H. Lechtman, Hist. Metall. 19, 141 (1985).

P.D. Budd, A Metallographic Investigation of Eneolithic Arsenical Copper (Bradford: University of Bradford, 1991).

P.D. Budd, Hist. Metall. 25, 99 (1991).

P.J. Northover, Old Work Archaeometallurgy, ed. A. Hauptmann, E. Pernicka, and G.A. Wagner (Bochum: Deutsches Bergbau-Museum, 1989), pp. 111–118.

J.R. Marechal, Métaux Corros. Ind. 33, 377 (1958).

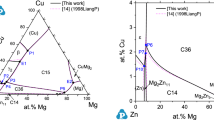

B.R. Subramanian and D.E. Laughlin, Bull. Alloy Phase Diagr. 9, 605 (1988).

B. Pei, B. Björkman, B. Jansson, and B. Sundman, Z. Metall. 85, 178 (1994).

D.M. Stefanescu, Science and Engineering of Casting Solidification (New York: Springer, 2015).

R.N. Grugel, J. Mater. Sci. 8, 677 (1993). https://doi.org/10.1007/BF01151244.

N.V. Ryndina and L.V. Kon‘kova, Sov. Archeol. 2, 30 (1982).

ASM Handbook: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials (ASM Handbook) Vol. 2.

E. Jochum-Zimmermann, N. Künzler-Wagner, and U. Kunnert, Exp. Archäol. Eur. 1, 285 (2005).

W. Kurz and D.J. Fisher, Fundamentals of Solidification (Baech: Trans Tech Publications, 1986).

A. Cziegler, Aspects of Grain Refinement in Copper Alloys, Master Thesis, Montanuniversität Leoben, 2015.

T. Ejima and M. Kameda, J. Jpn. Inst. Met. Mater. 1, 96 (1969).

M. Mödlinger and B. Sabatini, J. Archaeol. Sci. Rep. 16, 248 (2017). https://doi.org/10.1016/j.jasrep.2017.10.018.

M. Easton, C. Davidson, and D. St. John, Metall. Mater. Trans. A 41, 1528 (2010). https://doi.org/10.1007/s11661-010-0183-9.

M.B. Djurdjevic and M.A. Grzincic, Arch. Foundry Eng. 12, 19 (2012).

Acknowledgements

Dr. Benjamin J. Sabatini is an International Research Fellow of the Japan Society for the Promotion of Science (JSPS) No. PE17781. This work was also supported by the European Union’s Horizon 2020 research and innovation program under the Marie Skłodowska-Curie Actions Grant No. 656244.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sabatini, B.J., Cziegler, A. & Mödlinger, M. Casting Simulations of Arsenical Copper: New Insights into Prehistoric Metal Production and Materials. JOM 72, 3269–3278 (2020). https://doi.org/10.1007/s11837-020-04210-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04210-8