Abstract

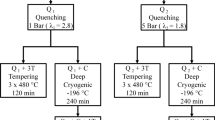

In order to study the effect of pulse current treatment on the mechanical properties, microstructure and cutting performance of YG8 cemented carbide, experiments were carried out by using self-made pulse current treatment device to treat cemented carbide samples with different current densities (J = 5, 10 and 15 A·mm−2). After the treatment of pulse current, when the current density increased from 5 to 15 A·mm−2, the hardness of the sample was improved to HV 1605, HV 1629 and HV 1653 from HV 1574; the transverse rupture strengths of the sample were 2136, 2289 and 2364 MPa, which were all higher than that of the untreated sample (2062 MPa), increasing by 3.6%, 11.0% and 14.6%, respectively; the corresponding cutting performance was increased by 10.1%, 13.9% and 19.4%, compared to that of the untreated tool. The tool’s life was also improved. After the treatment of pulse current, pulse current provided the driving force for dislocation motion, making it more likely for the dislocation to multiply and slip, the dislocation density was increased, and the mechanical properties were significantly improved.

Similar content being viewed by others

References

Xu JM, Hu H, Fu W, Li J, Jiang YM. Behaviors and mechanisms of friction and wear of special alloys at high temperature. J Steel Res. 2014;26(11):60.

Lin J, Zhao HY, Cai ZP, Huang SW, Lu XM, Ni SF. Reducing residual stresses in engineering structures by pulsed magnetic treatments. Tsinghua Univ (Sci & Tech). 2007;47(2):161.

Jiang Z, Wang L, Shi L, Wu YY. Study on tool wear mechanism and characteristics of carbide tools in cutting Ti6Al4V. J Mech Eng. 2014;50(1):178.

Wang X. Research on Prolonging Service Life of Cutting Tools Treated by Pulse Magnetization. Dalian: Dalian University of Technology; 2007. 1.

Li F, Regel LL, Wilcox WR. The influence of electric current pulses on the microstructure of the MnBi/Bi eutectic. J Cryst Growth. 2001;223(1):251.

Basmak JP, Sprecher AF, Conrad H. Colony(grain)size reduction of eutectic Pb-Sn castings by electropulsing. Scr Metall Mater. 1995;32(6):879.

Liao X, Zhai Q, Luo J. Refining mechanism of the electric current pulse on the solidification structure of pure aluminum. Acta Mater. 2007;55(9):3103.

Conrad H. Influence of an electric or magnetic field on the liquid-solid transformation in materials and on the microstructure of the solid. Mater Sci Eng A. 2000;287(2):205.

Gao M, He GH, Yang F, Guo JD, Yuan ZX, Zhou BL. Effect of electric current pulse on tensile strength and elongation of casting ZA27 alloy. Mater Sci Eng A. 2002;337(1–2):110.

Liao XL, Zhai QJ, Song CJ, Chen WJ, Gong YY. Effects of electric current pulse on stability of solid/liquid interface of Al–4.5 wt% Cu alloy during directional solidification. Mater Sci Eng A. 2007;466(1–2):56.

Song JL, Gi MF, Tang P, Liu JL, Qiu DS, Wang ZC. Reseach on fatigue properties of TC11 titanium alloy after electric pulse processing. Chin J Rare Met. 2018;42(7):691.

Zhang YL, Hou HL, Wang YQ. Superplasticity and microstructure evolution of 1420 Al–Li alloy with current pulse. Chin J Rare Met. 2017;41(12):1299.

Lv BC, Zhou YZ, Wang BQ, Guo JD. Effect of electropulsing on the fatigued heat-rolled 30CrMnSiA steel. Chin J Mater Res. 2003;17(1):16.

Levitin VV, Loskutov SV. The effect of a current pulse on the fatigue of titanium alloy. Solid State Commun. 2004;131(3):181.

Zhou YZ, Luo S, Ben HX, He GH. Experimental study on crack healing in steel using electric current pulse technique. Chin J Mater Res. 2003;17(2):169.

Yan J, Cen Q, Jiang Y, Zhou R. As-cast microstructure of high-boron middle-carbon alloy tool steel. J Mater Eng. 2013;6:55.

Zhan LC, Chi HX, Ma DS, Fu R, Jiang YH. The as-cast microstructure of ESR-CDS M2 high speed steel. J Mater Eng. 2013;24(7):29.

Li QY, Cen QH, Jiang YH, Zhou RF. Effects of electric pulse on solidification structure of high-boron middle-carbon alloy steel. Special Cast Nonferrous Alloys. 2012;32(12):1095.

Zhou JL, Huang ST, Peng RQ. Experimental research of cutting surface roughness for 45-hardened steel. Tool Technol. 2009;43(1):46.

Liu J, Wei C, Yang G, Wang LB, Wang L, Wu XL, Jiang K, Yang Y. A novel combined electromagnetic treatment on cemented carbides for improved milling and mechanical performances. Metall Mater Trans A. 2018;49(10):4798.

Yang Q, Zang HB. Effect of high-density pulse current treatment on microstructure and properties of GCr15 steel. Heat Treat Met. 2016;41(2):109.

Antolovich SD, Conrad H. The effects of electric currents and fields on deformation in metals, ceramics, and ionic materials: an interpretive survey. Mater Manuf Process. 2004;19(4):587.

Chen ZX, Ding HS, Chen RR, Guo JJ, Fu HZ. Microstructural evolution and mechanism of solidified TiAl alloy applied electric current pulse. Acta Metall Sin. 2019;55(5):611.

Yang C, Xu WC, Guo B, Shan DB, Zhang J. Healing of fatigue crack in 1045 Steel by using Eddy current treatment. Materials. 2016;9(8):641.

Song H, Wang ZJ. Microcrack healing and local recrystallization in pre-deformed sheet by high density electropulsing. Mater Sci Eng A. 2008;490(1):1.

Wang ZJ, Song H, Wang Z. Deformation behavior of TC1 titanium alloy sheet under double-sided pressure. Trans Nonferrous Met Soc China. 2008;18(1):72.

Song H, Wang Z. Improvement of mechanical properties of cold-rolled commercially pure Ti sheet by high density electropulsing. Trans Nonferrous Met Soc China. 2012;22(6):1350.

Song H, Wang ZJ, Gao TJ. Effect of high density electropulsing treatment on formability of TC4 titanium alloy sheet. Trans Nonferrous Met Soc China. 2007;17(1):87.

Xiao B, Yuan Y, Yu SX, Gao YZ. Deformation behavior and crack propagation on interface of Al/Cu laminated composites in uniaxial tensile test. Rare Met. 2020;39(3):296.

Takebayashi TK, Kunieda T, Yoshinaga N. Comparison of the dislocation density in martensite steels evaluated by some X-ray diffraction methods. ISIJ Int. 2010;50(6):875.

Wang HM, Peng ZX, Li GR, Li PS. Mechanism of high magnetic field on aluminum matrix composites dislocation density. J Central South Univ (Sci Technol). 2017;48(2):325.

Williamson GK, Smallman RE. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray Debye–Scherrer spectrum. Philos Mag A. 1956;1(1):34.

Zlateva G, Martinova Z. Microstructure of Metals and Alloys: An Atlas of Transmission Electron Microscopy. 2nd ed. London: CRC Press; 2008. 34.

Liu LP. Effects of Electric Field on Recovery and Recrystallization Microstructures and Textures of High Purity Aluminum Sheet. Shenyang: Northeastern University; 2007. 7.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Nos. 51575369 and 51675357).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, L., Yang, Y. & Yang, G. Microstructure and properties of YG8 cemented carbide with different pulse currents. Rare Met. 39, 597–606 (2020). https://doi.org/10.1007/s12598-020-01399-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01399-0