Abstract

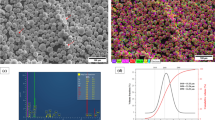

Revealing grains and very fine dendrites in a solidified weld metal of aluminum-magnesium-silicon alloys is difficult and thus, there is no evidence to validate the micro- and meso-scale physical models for hot cracks. In this research, the effect of preheating on the microstructure and hot crack creation in the pulsed laser welding of AA 6061 was investigated by an optical microscope and field emission electron microscopy. Etching was carried out in the gas phase using fresh Keller’s reagent for 600 s. The results showed that the grain size of the weld metal was proportional to the grain size of the base metal and was independent of the preheating temperature. Hot cracks passed the grain boundaries of the weld and the base metal. Lower solidification rates in the preheated samples led to coarser arm spacing; therefore, a lower cooling rate. Despite the results predicted by the micro and meso-scale models, lower cooling rates resulted in increased hot cracks. The cracks could grow in the weld metal after solidification; therefore, hot cracks were larger than predicted by the hot crack prediction models.

Similar content being viewed by others

References

American Society for Metals, ASM Handbook: Properties and Selection Nonferrous Alloys and Special Purpose Materials, ASM International, USA, 1990, p. 401.

Y.M. Zhang, C. Pan, and A.T. Male, Improved microstructure and properties of 6061 aluminum alloy weldments using a double-sided arc welding process, Metall. Mater. Trans. A, 31(2000), No. 10, p. 2537.

American Society for Metals, ASM Handbook, Welding Brazing and Soldering, ASM International, USA, 1992, p. 1395.

T. Soysal and S. Kou, A simple test for assessing solidification cracking susceptibility and checking validity of susceptibility prediction, Acta Mater., 143(2018), p. 181.

R.R. Ambriz, G. Mesmacque, A. Ruiz, A. Amrouche, and V.H. López, Effect of the welding profile generated by the modified indirect electric arc technique on the fatigue behavior of 6061-T6 aluminum alloy, Mater. Sci. Eng. A, 527(2010), No. 7–8, p. 2057.

L. Katgerman and D.G. Eskin, In search of the prediction of hot cracking in aluminium alloys, [in] T. Böllinghaus, H. Herold, C.E. Cross, and J.C. Lippold, eds., Hot Cracking Phenomena in Welds II , Springer, Berlin, Heidelberg, 2008, p. 11.

M. Wolf, T. Kannengießer, and T. Böllinghaus, Determination of critical strain rate for solidification cracking by numerical simulation, [in] T. Böllinghaus, H. Herold, C.E. Cross, and J.C. Lippold, eds., Hot Cracking Phenomena in Welds II , Springer, Berlin, Heidelberg, 2008, p. 77.

A. Niel, C. Bordreuil, F. Deschaux-Beaume, and G. Fras, Modelling hot cracking in 6061 aluminium alloy weld metal with microstructure based criterion, Sci. Technol. Weld. Joining, 18(2013), No. 2, p. 154.

S. Kou, A criterion for cracking during solidification, Acta Mater., 88(2015), p. 366.

H.R.Z. Rajani and A.B. Phillion, A mesoscale solidification simulation of fusion welding in aluminum-magnesium-silicon alloys, Acta Mater., 77(2014), p. 162.

H.R.Z. Rajani and A.B. Phillion, 3-D multi-scale modeling of deformation within the weld mushy zone, Mater. Des., 94(2016), p. 536.

D.G. Eskin and L. Katgerman, A quest for a new hot tearing criterion, Metall. Mater. Trans. A, 38(2007), No. 7, p. 1511.

M. Rappaz, J.M. Drezet, and M. Gremaud, A new hot-tearing criterion, Metall. Mater. Trans. A, 30(1999), No. 2, p. 449.

N. Coniglio and C.E. Cross, Mechanisms for solidification crack initiation and growth in aluminum welding, Metall. Mater. Trans. A, 40(2009), No. 11, p. 2718.

C.E. Cross, N. Coniglio, P. Schempp, and M. Mousavi, Critical conditions for weld solidification crack growth, [in] T. Böllinghaus, J.C. Lippold, and C.E. Cross eds., In Hot cracking phenomena in welds III , Springer, 2011, p. 25.

H.R.Z. Rajani and A.B. Phillion, 3D multi-scale multi-physics modelling of hot cracking in welding, Mater. Des., 144(2018), p. 45.

M. Sheikhi, F.M. Ghaini, and H. Assadi, Prediction of solidification cracking in pulsed laser welding of 2024 aluminum alloy, Acta Mater., 82(2015), p. 491.

M. Sheikhi, F.M. Ghaini, and H. Assadi, Solidification crack initiation and propagation in pulsed laser welding of wrought heat treatable aluminium alloy, Sci. Technol. Weld. Joining, 19(2014), No. 3, p. 250.

P. von Witzendorff, S. Kaierle, O. Suttmann, and L. Overmeyer, In situ observation of solidification conditions in pulsed laser welding of AL6082 aluminum alloys to evaluate their impact on hot cracking susceptibility, Metall. Mater. Trans. A, 46(2015), No. 4, p. 1678.

M.A. Abdulstaar, K.J. Al-Fadhalah, and L. Wagner, Micoostructural variation through weld thickness and mechanical properties of peened friction stir welded 6061 aluminum alloy joints, Mater. Charact., 126(2017), p. 64.

Q. Chu, R. Bai, H. Jian, Z. Lei, N. Hu, and C. Yan, Microstructure, texture and mechanical properties of 6061 aluminum laser beam welded joints, Mater. Charact., 137(2018), p. 269.

S.D. Ji, X.C. Meng, Z.L. Liu, R.F. Huang, and Z.W. Li, Dissimilar friction stir welding of 6061 aluminum alloy and AZ31 magnesium alloy assisted with ultrasonic, Mater. Lett, 201(2017), p. 173.

P. Sadeesh, M.V. Kannan, V. Rajkumar, P. Avinash, N. Arivazhagan, K.D. Ramkumar, and S. Narayanan, Studies on friction stir welding of AA 2024 and AA 6061 dissimilar metals, Procedia Eng., 75(2014), p. 145.

A. Heidarzadeh, H. Khodaverdizadeh, A. Mahmoudi, and E. Nazari, Tensile behavior of friction stir welded AA 6061-T4 aluminum alloy joints, Mater. Des., 37(2012), p. 166.

S. Kou, Welding Metallurgy, John Wiley & Sons, Inc., New Jersey, 2003, p. 199.

S. McFadden and D.J. Browne, A generalised version of an Ivantsov-based dendrite growth model incorporating a facility for solute measurement ahead of the tip, Comput. Mater. Sci., 55(2012), p. 245.

H. Hekmatjou and H. Naffakh-Moosavy, Hot cracking in pulsed Nd: YAG laser welding of AA5456, Opt. Laser Technol., 103(2018), p. 22.

Acknowledgement

The authors would like to thank the metallography laboratory personnel of University of Tehran for their cooperation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ebrahimzadeh, H., Farhangi, H., Mousavi, S.A.A.A. et al. Microstructural analyses of aluminum-magnesium-silicon alloys welded by pulsed Nd: YAG laser welding. Int J Miner Metall Mater 27, 660–668 (2020). https://doi.org/10.1007/s12613-020-2027-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2027-y