Abstract

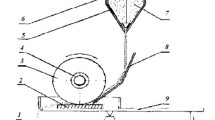

In this paper, we studied the wear of a plasma thin-film coating (PTFC) of the Si–O–N–C system deposited on high-speed steel of the W6Mo5Cr4V2 type. The tests were performed using a friction machine according to the “disk-indenter” scheme under dry friction conditions by the adhesive and abrasive wear mechanism. A steel indenter was used to simulate adhesive wear and a corundum indenter was employed to simulate abrasive wear. The positive effect of the coating on the wear resistance of the sample surface was established. The obtained positive effect has been shown to be achieved as a result of a combination of four factors: high coating hardness, phase hardening of the base material, reduction of surface roughness, and partial prevention of adhesion bonding of contacting bodies. Within the depth of the material hardening zone formed upon the PTFC deposition, the wear resistance of W6Mo5Cr4V2 steel was shown to increase by 3.2 times when paired with a steel indenter and 2.4 times when paired with a corundum indenter. We concluded that a PTFC thickness of 0.8–1 μm is sufficient to increase the wear resistance of high-speed steel products and to provide an acceptable level of coating adhesion.

Similar content being viewed by others

REFERENCES

Topolyanskii, G.L. and Sosnin, N.A., Deposition of wear-resistant coatings using plasma welding equipment, Svar. Proizvod., 1989, no. 5, pp. 30–31.

Sosnin, N.A., Ermakov, S.A., and Topolyanskii, P.A., Plazmennye tekhnologii. Rukovodstvo dlya inzhenerov (Plasma Technologies: Guide for Engineers), St. Petersburg: S.-Peterb. Gos. Politekh. Univ., 2013.

Gorlenko, A.O., Topolyanskii, P.A., Topolyanskii, A.P., Sosnin, N.A., Ermakov, S.A., and Erokhin, A.N., Finishing plasma hardening technology to increase the service life of a metal cutting tool, Mashinostr. Tekhnol. Instrum., 2013, no. 3 (299), pp. 66–73.

Bendeddouche, A., Berjoan, R., Beche, E., et al., Structural characterization of amorphous SiCxNy chemical vapor deposited coatings, J. Appl. Phys., 1997, vol. 81, pp. 6147–6154.

Chen, C.W., Huang, C.C., Lin, Y.Y., Chen, L.C., and Chen, K.H., The affinity of Si–N and Si–C bonding in amorphous silicon carbon nitride (a-SiCN) thin film, Diamond Relat. Mater., 2005, vol. 14, nos. 3–7, pp. 1126–1130.

Roikh, I.L. and Koltunova, L.N., Zashchitnye vakuumnye pokrytiya na stali (Protective Vacuum Coatings on Steel), Moscow: Mashinostroenie, 1971.

Zimon, A.D., Adgeziya plenok i pokrytii (Adhesion of Films and Coatings), Moscow: Khimiya, 1977.

Hamm, S.C., Waidmann, J., Mathai, J.C., Gangopadhyay, K., Currano, L., and Gangopadhyay, S., Characterization and versatile applications of low hydrogen content SiOCN grown by plasma-enhanced chemical vapor deposition, J. Appl. Phys., 2014, vol. 116, art. ID 104902.

Zhou, Y., Yan, X., Kroke, E., Riedel, R., Probst, D., Thissen, A., Hauser, R., Ahles, M., and von Seggern, H., Deposition temperature effect on the structure and optical property of RF-PACVD-derived hydrogenated SiCNO film, Materialwiss. Werkstofftech., 2006, vol. 37, no. 2, pp. 173–177.

Jin, S.B., Lee, J.S., Choi, Y.S., Choi, I.S., Han, J.G., and Hori, M., Improving the gas barrier properties of a-SiOxCyNz film at low temperature using high energy and suitable nitrogen flow rate, Curr. Appl. Phys., 2013, vol. 13, pp. 885–889.

Zambov, L.M., Ivanov, B., Popov, C., Georgiev, G., Stoyanov, I., and Dimitrov, D.B., Characterization of low-dielectric constant SiOCN films synthesized by low pressure chemical vapor deposition, J. Phys. IV, 2001, vol. 11, pp. Pr3-1005–Pr3-1012.

Gorlenko, A.O., Shupikov, I.L., Topolyanskii, P.A., and Topolyanskii, A.P., Modification of the working surfaces of parts by deposition of reinforcing nanocoating, Metalloobrabotka, 2012, no. 2, pp. 31–36.

Topolyanskii, P.A., Ermakov, S.A., Sosnin, N.A., and Topolyanskii, A.P., Comparative analysis of the properties of wear-resistant coatings to increase drill resistance, Metalloobrabotka, 2013, no. 4 (76), pp. 28–39.

Rastegaev, I.A. and Afanas’ev, M.A., Evaluation of the results of tribological tests by laser scanning confocal microscopy, Izv. Samar. Nauch. Tsentra,Ross. Akad. Nauk, 2015, vol. 17, no. 1, pp. 187–190.

Rastegaev, I.A., Merson, D.L., Vinogradov, A.Yu., and Danyuk, A.V., Technique for the determination of the critical points under acoustic emission tribological tests, Inorg. Mater., 2017, vol. 53, no. 15, pp. 1506–1512.

Rastegaev, I., Merson, D., and Vinogradov, A., Real time acoustic emission methodology in effective tribology testing, Int. J. Microstruct,Mater. Prop., 2014, vol. 9, nos. 3–5, pp. 360–373.

Geller, Yu.A., Instrumental’nye stali (Tool Steels), Moscow: Metallurgiya, 1975.

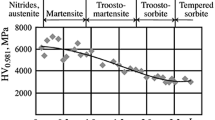

Korotkov, V.A., Rastegaev, I.A., Merson, D.L., and Afanas’ev, M.A., Investigation of the effect of the plasma thin-film coating system Si–O–C–N on the surface hardening of high-speed steel, J. Surf. Invest.: X-ray, Synchrotron Neutron Tech., 2020, vol. 14, no. 2, pp. 267–274 (in press).

Funding

This work was supported by the Ministry of Science and Higher Education of the Russian Federation, project no. 11.8236.2017/9.10.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by A. Ivanov

About this article

Cite this article

Rastegaev, I.A., Rastegaeva, I.I., Merson, D.L. et al. The Wear Features of a Plasma Thin-Film Coating on High-Speed Steel. J. Frict. Wear 41, 160–168 (2020). https://doi.org/10.3103/S1068366620020117

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366620020117