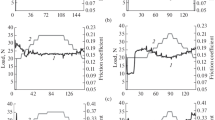

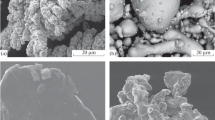

Abstract—The use of titanium nitride coatings as materials for friction clutches is considered. The paper presents the results of studying the tribotechnical properties of a titanium nitride coating under sliding friction with a lubricant in a friction pair with a metal surface. The possibility of using a titanium nitride coating for friction without lubrication in contact with a fluoroplastic has been investigated. It is shown that a titanium nitride coating can be considered a promising material for the contact surfaces of friction clutches, preventing a decrease in the friction coefficient with increasing temperature.

Similar content being viewed by others

REFERENCES

Fedorchenko, I.M., Kryachek, V.M., and Panaoiti, I.I., Sovremennye friktsionnye mekhanizmy (Modern Friction Mechanisms), Kyiv: Naukova Dumka, 2005.

Shishkarev, M.P. and Kobzev, K.O., Calculations and design of adaptive friction clutches, Naukovedenie, 2013, no. 5, pp. 1–7.

Khomichev, A.S., Friction elements of modern automatic transmissions: materials, operation conditions, and loads, Vestn. Izhevsk. Gos. Tekh. Univ., 2009, no. 2, pp. 36–38.

Skadorva, A.F. and Kartashevich, A.N., Assessing criteria of the quality of friction clutch of the gearbox of a BELARUS-2103 caterpillar tractor, Vestn. Bel.-Ross. Univ., 2014, no. 4 (45), pp. 80–91.

Morozov, A.V. and Veprinyak, A.I., Evaluation of friction forces of the friction clutch, Materialy IX Mezhdunarodnoi nauchnoi konferentsii “Teoriya i praktika sovremennoi nauki,” g. Moskva, 26–27 marta 2013 g. (Proc. IX Int. Sci. Conf. “Theory and Practice of Modern Science,” Moscow, March 26–27, 2013), Moscow: Spetskniga, 2013.

Elagina, O.Yu., Tekhnologicheskie metody povysheniya iznosostoikosti detalei mashin (Technological Improvement of Wear Resistance of Machine Parts), Moscow: Universitetskaya Kniga, 2009.

Latushkina, S.D., Kuis, D.V., Rudak, P.V., Romanov, I.M., Zhizhchenko, A.G., Gapanovich, O.I., and Pisku-nova, O.Yu., Multicomponent coatings deposited from separated vacuum-arc plasma, Materialy konferentsii “Tekhnologii uprochneniya, naneseniya pokrytii i remonta: teoriya i praktika–2013,” g. Sankt-Peterburg, 16–19 aprelya 2013 (Proc. Conf. “Technologies of Strengthening, Coating, and Reparation: Theory and Practice–2013,” St. Petersburg, April 16–19, 2013), St. Petersburg: S.‑Peterb. Gos. Politekh. Univ., 2013, pp. 182–184.

Kuleshov, A.K., Khodasevich, V.V., Uglov, V.V., Anishchak, V.M., and Danilenok, M.M., Thermostability of the surface layers of titanium and chromium nitrides formed by condensation with ion bombardment on the T5K10 hard alloy, Perspekt. Mater., 2009, no. 2, 68–73.

Latushkina, S.D., Romanov, I.M., Zhizhchenko, A.G., and Posylkina, O.I., Vacuum-arc nanocrystalline coatings based on titanium nitride, Perspekt. Mater., 2014, no. 6, pp. 49–55.

Malyshev, V., Dörr, N., Elagina, O.Yu., and Rodríguez Ripoll, M., Tribological performance of micro-arc oxidation coatings with base oils, Tribol. Schmierungs Tech., 2018, no. 5, pp. 5–11.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Elagina, O.Y., Komadynko, A.C., Poleshchuk, E.D. et al. Prospects for Using Titanium Nitride Coatings for the Contact Surfaces of Friction Clutches. J. Frict. Wear 41, 25–30 (2020). https://doi.org/10.3103/S1068366620010067

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366620010067