Abstract

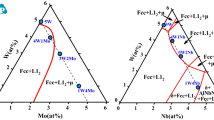

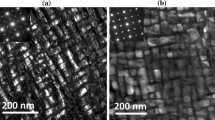

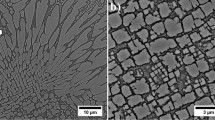

The Ni–Co–Cr–W–Mo system is critical for the design of nickel-based superalloys. This system stabilizes different topologically close-packed (TCP) phases in many commercially superalloys with high W and Mo contents. Scanning electron microscopy (SEM), transmission electron microscopy (TEM) and thermodynamic calculations were applied to investigate the thermodynamics of the precipitates in two different W-contained Ni–Co–Cr–W–Mo superalloys (Alloy 1 and Alloy 2). Computational thermodynamics verifies the experimental observation of the μ phase formation as a function of temperature and alloy chemistry, but the kinetics for the precipitation of the M6C phase do not agree with the experimental findings. The major precipitates of Alloy 1 at temperatures of 700 °C and 750 °C during long-time exposure are M23C6, γ′ phase and MC; for Alloy 2, they are M23C6, γ′ phase, MC, M6C and μ phase. W addition is found to promote the precipitation of M6C and μ phase during exposure. M6C has higher W and lower Ni content than μ phase, whereas M6C is an unstable phase that would transform into M12C after 5000-h exposure at 750 °C. A great quantity of needle-like μ phases precipitated after exposure at 750 °C for 5000 h, which have no effect on the impact properties of Alloy 2.

Similar content being viewed by others

References

Jablonski PD, Hawk JA, Cowen CJ, Maziasz PJ. Processing of advancedcast alloys for A-USC steam turbine applications. JOM. 2012;64:271.

Liu ZD, Heng SC, Tang GB, Bao HS, Yang G, Gan Y. The state-of-the-art of steel technology used for Chinese power plants and its future. Iron Steel. 2011;46(3):1.

Agarwal DC, Gehrmann B. Nickel alloys for high efficiency fossil power plants. In: The 5th International Conference in Materials Technology for Fossil Power Plants. Florida. 2007. 271.

Fukuda Y. Development of advanced ultra supercritical fossil power plants in Japan: materials and high temperature corrosion properties. Mater Sci Forum. 2011;696:236.

Ma LT, Wang LM. Hot deformation behavior of F6NM stainless steel. Int J Iron Steel Res. 2014;21(11):1035.

Yamamoto R, Kadoya Y, Nakano T. Development of Ni-based superalloy for advanced 700 °C-class steam turbines. In: Proceedings from the Fifth International Conference on Advances in Materials Technology for Fossil Power Plant, Florida, 2007.434.

Bugge J, Kjær S, Blum R. High-efficiency coal-fired power plants development and perspectives. Energy. 2006;31(10):1437.

Gong ZH, Yang G, Ma LT, Wang L. Precipitation phases and mechanical properties of GY200 Ni-based alloy for blade with W and Mo addition. Chin J Rare Met. 2018;42(3):246.

Abe F. Research and development of heat-resistant materials for advanced USC power plants with steam temperatures of 700 °C and above. Engineering. 2015;1(2):211.

Kuramochi T. Review of energy and climate policy developments in Japan before and after Fukushima. Renew Sustain Energy Rev. 2015;43:1320.

Shao WW, Zhang B, Liu Y, Liu CS, Tan P, Shang S, Zhang GP. Effect of laser power on porosity and mechanical properties of GH4169 fabricated by laser melting deposition. Tungsten. 2019;1(4):297.

Abe F, Kutsumi H, Haruyama H, Okubo H. Improvement of oxidation resistance of 9 mass% chromium steel for advanced-ultra supercritical power plant boilers by pre-oxidation treatment. Corros Sci. 2017;114:1.

Zheng L, Xiao CB, Zhang GQ. Brittle fracture of gas turbine blade caused by the formation of primary β-NiAl phase in Ni-base superalloy. Eng Fail Anal. 2012;26:318.

Kim IS, Choi BG, Hong HU, Do J, Jo CY. Influence of thermal exposure on the microstructural evolution and mechanical properties of a wrought Ni-base superalloy. Mater Sci Eng A. 2014;593:55.

Pyczak F, Neumeier S, Göken M. Temperature dependence of element partitioning in rhenium and ruthenium bearing nickel-base superalloys. Mater Sci Eng A. 2010;527:7939.

Popp R, Haas S, Scherm F, Redermeier A, Povoden-Karadeniz E, Göhler T, Glatzel U. Determination of solubility limits of refractory elements in TCP phases of the Ni–Mo–Cr ternary system using diffusion multiples. J Alloys Compd. 2019;788:67.

Hobbs RA, Zhang L, Rae CMF, Tin S. Mechanisms of topologically close-packed phase suppression in an experimental ruthenium-bearing single-crystal nickel-base superalloy at 1100 °C. Metall Mater Trans A. 2008;39A:1014.

Belan J. GCP and TCP phases presented in nickel-base superalloys. Mater Today Proc. 2016;3(4):936.

Zhao JC, Ravikumar V, Beltran AM. Phase precipitation and phase stability in Nimonic 263. Metall Mater Trans A. 2001;32(6):1271.

Huo J, Shi Q, Zheng Y, Feng Q. Microstructural characteristics of σ phase and P phase in Ru-containing single crystal superalloys. Mater Char. 2017;124:73.

Mao P, Xin Y, Han K, Jiang W. Effects of heat treatment and Re-content on the TCP-phase in two Ni–Mo–Cr–Re superalloys. Acta Metall Sin. 2009;22(5):365.

Rettig R, Heckl A, Singer RF. Modeling of precipitation kinetics of TCP-phases in single crystal nickel-base superalloys. Adv Mater Res. 2011;278:180.

Park CJ, Ahn MK, Kwon HS. Influences of Mo substitution by W on the precipitation kinetics of secondary phases and the associated localized corrosion and embrittlement in 29% Cr ferritic stainless steels. Mater Sci Eng A. 2006;418(1–2):211.

Wang L, Yang G, Liu ZD, Wang L, Ma LT, Yang ZQ. Effects of long-term aging on microstructure and mechanical properties of a nickel-base alloy. Rare Met Mater Eng (Chines). 2018;47(3):961.

Viswanathan GB, Shi R, Genc A, Vorontsov VA, Kovarik L, Rae CMF, Mills MJ. Segregation at stacking faults within the γ′ phase of two Ni-base superalloys following intermediate temperature creep. Scripta Materialia. 2015;94:5.

Fleischmann E, Miller MK, Affeldt E, Glatzel U. Quantitative experimental determination of the solid solution hardening potential of rhenium, tungsten and molybdenum in single-crystal nickel-based superalloys. Acta Mater. 2015;87:350.

Li HF, Ye F, Zhao J, Cao TS, Xu FH, Xu QS, Wang Y, Cheng CQ, Min XH. Grain boundary migration-induced directional coarsening of the γ′ phase in advanced ultra-supercritical superalloy. Mater Sci Eng A. 2018;714:172.

Idell Y, Levine LE, Allen AJ, Zhang F, Campbell CE, Olson GB, Gong J, Deutchman HZ. Unexpected δ-phase formation in additive-manufactured Ni-based superalloy. JOM. 2016;68(3):950.

Chen Z, Brooks JW, Loretto MH. Precipitation in Incoloy alloy 909. Mater Sci Technol. 1993;9(8):647.

Kermanpur A, Varahraam N, Engilehei E, Mohammadzadeh M, Davami P. Directional solidification of Ni base superalloy IN738LC to improve creep properties. Mater Sci Technol. 2000;16:579.

Reed RC, Jackson MP, Na YS. Characterization and modeling of the precipitation of the sigma phase in UDIMET 720 and UDIMET 720LI. Metall Mater Trans A. 1999;30:521.

Acknowledgements

This study was financially supported by the National Key Research and Develop Program, China (No. 2017YFB0305203).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bao, HS., Gong, ZH., Chen, ZZ. et al. Evolution of precipitates in Ni–Co–Cr–W–Mo superalloys with different tungsten contents. Rare Met. 39, 716–724 (2020). https://doi.org/10.1007/s12598-020-01400-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01400-w