Abstract

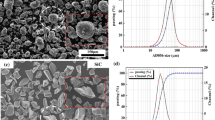

In this study, Ti-6Al-4V (TC4) coating was prepared using an in situ shot peening-assisted cold spraying technology in which large shot peening particles were mixed with TC4 spraying powders to prepare the deposit. To improve its strength and toughness, the coating was heat-treated at 600-1000 °C in vacuum. The results demonstrated that the microstructure of the as-sprayed coating exhibited a special structure that was denser at the regions tamped by the shot peening particles and porous at the nontamped regions. When the coating was heat-treated at 800 and 1000 °C, the interface between the particles had largely disappeared and the local pores had interconnected with each other due to thermal diffusion and recrystallization. The coating hardness decreased slightly after annealing at 600 and 800 °C due to the released strain hardening effect. The bonding strength of the coating after annealing improved in comparison with that of the as-sprayed coating. The tensile strength of the coating improved significantly under annealing at 800 °C. A cross-linked high densification network was formed after annealing due to the effect of in situ shot peening, which served as a reinforced framework and enhanced the strength of the coating.

Similar content being viewed by others

References

M. Peters, J. Kumpfert, C.H. Ward, and C. Leyens, Titanium Alloys for Aerospace Applications (p 419-427), Adv. Eng. Mater., 2010, 5(6), p 419-427

R.R. Boyer, An Overview on the Use of Titanium in the Aerospace Industry, Mater. Sci. Eng., A, 1996, 213(1-2), p 103-114

M. Peters, J. Hemptenmacher, J. Kumpfert, and C. Leyens, Structure and Properties of Titanium and Titanium Alloys, Wiley-VCH Verlag GmbH & Co. KGaA, Hoboken, 2003

A.M. Birt, V.K. Champagne, R.D. Sisson, and D. Apelian, Microstructural Analysis of Cold-Sprayed Ti-6Al-4 V at the Micro- and Nano-Scale, J. Therm. Spray Technol., 2015, 24(7), p 1277-1288

S.H. Zahiri, C.I. Antonio, and M. Jahedi, Elimination of porosity in directly fabricated titanium via cold gas dynamic spraying, J. Mater. Process. Technol., 2009, 209(2), p 922-929

K. Kim, S. Kuroda, M. Watanabe, R. Huang, H. Fukanuma, and H. Katanoda, Comparison of Oxidation and Microstructure of Warm-Sprayed and Cold-Sprayed Titanium Coatings, J. Therm. Spray Technol., 2011, 21(3-4), p 550-560

T. Hussain, D.G. McCartney, P.H. Shipway, and T. Marrocco, Corrosion Behavior of Cold Sprayed Titanium Coatings and Free Standing Deposits, J. Therm. Spray Technol., 2010, 20(1-2), p 260-274

S.H. Zahiri, D. Fraser, and M. Jahedi, Recrystallization of Cold Spray-Fabricated CP Titanium Structures, J. Therm. Spray Technol., 2008, 18(1), p 16-22

A.M. Birt, V.K. Champagne, R.D. Sisson, and D. Apelian, Microstructural Analysis of Ti-6Al-4V Powder for Cold Gas Dynamic Spray Applications, Adv. Powder Technol., 2015, 26(5), p 1335-1347

D.I. Adebiyi, A.P.I. Popoola, and I. Botef, Low Pressure Cold Spray Coating of Ti-6Al-4 V with SiC-Based Cermet, Mater. Lett., 2016, 175, p 63-67

G.-R. Li and L.-S. Wang, Durable TBCs with Self-enhanced Thermal Insulation Based on Co-design on Macro-and Microstructure, Appl. Surf. Sci., 2019, 483, p 472-480

M.R. Rokni, C.A. Widener, S.P. Ahrenkiel, B.K. Jasthi, and V.R. Champagne, Annealing Behaviour of 6061 Aluminium Deposited by High Pressure Cold Spray, Surf. Eng., 2014, 30(5), p 361-368

M.R. Rokni, C.A. Widener, G.A. Crawford, and M.K. West, An Investigation into Microstructure and Mechanical Properties of Cold Sprayed 7075 Al Deposition, Mater. Sci. Eng., A, 2015, 625, p 19-27

C. Borchers, F. Gartner, T. Stoltenhoff, and H. Kreye, Microstructural Bonding Features of Cold Sprayed Face Centered Cubic Metals, J. Appl. Phys., 2004, 96(8), p 4288-4292

M. Fukumoto, M. Mashiko, M. Yamada, and E. Yamaguchi, Deposition Behavior of Copper Fine Particles onto Flat Substrate Surface in Cold Spraying, J. Therm. Spray Technol., 2010, 19(1-2), p 89-94

X.T. Luo, C.X. Li, F.L. Shang, G.J. Yang, Y.Y. Wang, and C.J. Li, High Velocity Impact Induced Microstructure Evolution During Deposition of Cold Spray Coatings: A Review, Surf. Coat. Technol., 2014, 254(10), p 11-20

W.-Y. Li, C. Zhang, X. Guo, J. Xu, C.-J. Li, H. Liao, C. Cocidet, and K.A. Khor, Ti and Ti-6Al-4 V Coatings by Cold Spraying and Microstructure Modification by Heat Treatment, Adv. Eng. Mater., 2007, 9(5), p 418-423

T. Marrocco, D.G. Mccartney, P.H. Shipway, and A.J. Sturgeon, Production of Titanium Deposits by Cold-Gas Dynamic Spray: Numerical Modeling and Experimental Characterization, J. Therm. Spray Technol., 2006, 15(2), p 263-272

P. Vo, D. Goldbaum, W. Wong, E. Irissou, J.G. Legoux, R.R. Chromik and S. Yue, Cold-Spray Processing of Titanium and Titanium Alloys (2015)

H. Fukanuma, N. Ohno, A Study of Adhesive Strength of Cold Spray Coatings, pp. 329-334 (2004)

R.E. Blose, B.H. Walker, R.M. Walker, and S.H. Froes, New Opportunities to Use Cold Spray Process for Applying Additive Features to Titanium Alloys, Met. Powder Rep., 2006, 61(9), p 30-37

N.W. Khun, A.W.Y. Tan, K.J.W. Bi, and E. Liu, Effects of Working Gas on Wear and Corrosion Resistances of Cold Sprayed Ti-6Al-4 V Coatings, Surf. Coat. Technol., 2016, 302, p 1-12

C.-J. Li and W.-Y. Li, Deposition Characteristics of Titanium Coating in Cold Spraying, Surf. Coat. Technol., 2003, 167(2-3), p 278-283

X.-T. Luo, Y.-K. Wei, Y. Wang, and C.-J. Li, Microstructure and Mechanical Property of Ti and Ti6Al4 V Prepared by an In-Situ Shot Peening Assisted Cold Spraying, Mater. Des., 2015, 85, p 527-533

H. Zhou, C. Li, G. Ji, S. Fu, H. Yang, X. Luo, G. Yang, and C. Li, Local Microstructure Inhomogeneity and Gas Temperature Effect in In-Situ Shot-Peening Assisted Cold-Sprayed Ti-6Al-4 V Coating, J. Alloys Compd., 2018, 766, p 694-704

Y.Q. Ren, P.C. King, Y.S. Yang, T.Q. Xiao, C. Chu, S. Gulizia, and A.B. Murphy, Characterization of Heat Treatment-Induced Pore Structure Changes in Cold-Sprayed Titanium, Mater. Charact., 2017, 132, p 69-75

N. Kang, P. Coddet, H. Liao, and C. Coddet, Cold Gas Dynamic Spraying of a Novel Micro-alloyed Copper: Microstructure, Mechanical Properties, J. Alloys Compd., 2016, 686, p 399-406

W.-Y. Li, C. Yang, and H. Liao, Effect of Vacuum Heat Treatment on Microstructure and Microhardness of Cold-Sprayed TiN Particle-Reinforced Al Alloy-Based Composites, Mater. Des., 2011, 32(1), p 388-394

W. Li, K. Yang, S. Yin, X. Yang, Y. Xu, and R. Lupoi, Solid-State Additive Manufacturing and Repairing by Cold Spraying: A Review, J. Mater. Sci. Technol., 2018, 3, p 440-457

H. Assadi, H. Kreye, F. Gärtner, and T. Klassen, Cold Spraying—A Materials Perspective, Acta Mater., 2016, 116, p 382-407

R.N. Raoelison, C. Verdy, and H. Liao, Cold Gas Dynamic Spray Additive Manufacturing Today: Deposit Possibilities, Technological Solutions and Viable Applications, Mater. Des., 2017, 133, p 266-287

W. Wong, E. Irissou, J.G. Legoux, P. Vo, and S. Yue, Powder Processing and Coating Heat Treatment on Cold Sprayed Ti-6Al-4V Alloy, Mater. Sci. Forum, 2012, 706-709, p 258-263

P. Vo, E. Irissou, J.G. Legoux, and S. Yue, Mechanical and Microstructural Characterization of Cold-Sprayed Ti-6Al-4 V After Heat Treatment, J. Therm. Spray Technol., 2013, 22(6), p 954-964

G. Sundararajan, N.M. Chavan, and S. Kumar, The Elastic Modulus of Cold Spray Coatings: Influence of Inter-splat Boundary Cracking, J. Therm. Spray Technol., 2013, 22(8), p 1348-1357

G. Bae, S. Kumar, S. Yoon, K. Kang, H. Na, H.J. Kim, and C. Lee, Bonding Features and Associated Mechanisms in Kinetic Sprayed Titanium Coatings, Acta Mater., 2009, 57(19), p 5654-5666

H. Zhou, C. Li, H. Yang, X. Luo, G. Yang, W. Li, T. Hussain, and C. Li, Pores Structure Change Induced by Heat Treatment in Cold-Sprayed Ti6Al4 V Coating, J. Therm. Spray Technol., 2019, 28(6), p 1199-1211

B. Dikici, H. Yilmazer, I. Ozdemir, and M. Isik, The Effect of Post-Heat Treatment on Microstructure of 316L Cold-Sprayed Coatings and Their Corrosion Performance, J. Therm. Spray Technol., 2016, 25(4), p 704-714

B. Al-Mangour, R. Mongrain, E. Irissou, and S. Yue, Improving the Strength and Corrosion Resistance of 316L Stainless Steel for Biomedical Applications Using Cold Spray, Surf. Coat. Technol., 2013, 216, p 297-307

M.A. Garrido, P. Sirvent, and P. Poza, Evaluation of Mechanical Properties of Ti6Al4 V Cold Sprayed Coatings, Surf. Eng., 2017, 34(5), p 399-406

Z. Arabgol, M. Villa Vidaller, H. Assadi, F. Gärtner, and T. Klassen, Influence of Thermal Properties and Temperature of Substrate on the Quality of Cold-Sprayed Deposits, Acta Mater., 2017, 127, p 287-301

N.W. Khun, A.W.Y. Tan, W. Sun, and E. Liu, Effect of Heat Treatment Temperature on Microstructure and Mechanical and Tribological Properties of Cold Sprayed Ti-6Al-4V Coatings, Tribol. Trans., 2016, 60(6), p 1033-1042

R.C. Dykhuizen and M.F. Smith, Gas Dynamic Principles of Cold Spray, J. Therm. Spray Technol., 1998, 7(2), p 205-212

F. Gärtner, T. Stoltenhoff, J. Voyer, H. Kreye, S. Riekehr, and M. Koçak, Mechanical Properties of Cold-Sprayed and Thermally Sprayed Copper Coatings, Surf. Coat. Technol., 2006, 200(24), p 6770-6782

M.K. Decker, Microstructure and Properties of Cold Spray Nickel, in Proceedings of the itsc singapore, vol 433 (2001)

G. Bae, K. Kang, J.-J. Kim, and C. Lee, Nanostructure Formation and Its Effects on the Mechanical Properties of Kinetic Sprayed Titanium Coating, Mater. Sci. Eng., A, 2010, 527(23), p 6313-6319

X. Qiu, J.-Q. Wang, L. Gyansah, J.-X. Zhang, and T.-Y. Xiong, Effect of Heat Treatment on Microstructure and Mechanical Properties of A380 Aluminum Alloy Deposited by Cold Spray, J. Therm. Spray Technol., 2017, 26(8), p 1898-1907

M. Grujicic, C.L. Zhao, W.S. DeRosset, and D. Helfritch, Adiabatic Shear Instability Based Mechanism for Particles/Substrate Bonding in the Cold-Gas Dynamic-Spray Process, Mater. Des., 2004, 25(8), p 681-688

K. Yang, W. Li, X. Yang, and Y. Xu, Anisotropic Response of Cold Sprayed Copper Deposits, Surf. Coat. Technol., 2018, 335, p 219-227

B. Derby and E.R. Wallach, Diffusion Bonding: Development of Theoretical Model, Met. Sci. J., 2013, 18(9), p 427-431

R. Huang, M. Sone, W. Ma, and H. Fukanuma, The Effects of Heat Treatment on the Mechanical Properties of Cold-Sprayed Coatings, Surf. Coat. Technol., 2015, 261, p 278-288

A.W.-Y. Tan, W. Sun, Y.P. Phang, M. Dai, I. Marinescu, Z. Dong, and E. Liu, Effects of Traverse Scanning Speed of Spray Nozzle on the Microstructure and Mechanical Properties of Cold-Sprayed Ti6Al4V Coatings, J. Therm. Spray Technol., 2017, 26(7), p 1484-1497

L. Zeng and T. Bieler, Effects of Working, Heat Treatment, and Aging on Microstructural Evolution and Crystallographic Texture of α, α′, α″and β Phases in Ti-6Al-4V Wire, Mater. Sci. Eng., A, 2005, 392(1-2), p 403-414

M. Peters, J. Hemptenmacher, J. Kumpfert, C. Leyens, Structure and Properties of Titanium and Titanium Alloys, in Titanium and Titanium Alloys: Fundamentals and Applications, pp. 1-36 (2003)

B. Vrancken, L. Thijs, J.-P. Kruth, and J. Van Humbeeck, Heat Treatment of Ti6Al4V Produced by Selective Laser Melting: Microstructure and Mechanical Properties, J. Alloys Compd., 2012, 541, p 177-185

Acknowledgments

The authors would like to thank the financial support by the National Science Fund of China (No. 51761145108).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, H., Li, C., Luo, X. et al. Microstructure of Cross-Linked High Densification Network and Strengthening Mechanism in Cold-Sprayed Ti-6Al-4V Coating After Heat Treatment. J Therm Spray Tech 29, 1054–1069 (2020). https://doi.org/10.1007/s11666-020-01042-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01042-5