Abstract

Magnesium exhibits substantial property enhancement for a vast range of applications via alloying by rare earth elements (REs). The effect of different amounts of alloying elements (Zn and REs such as Gd, Y and Nd) on the microstructure, texture and mechanical properties of Mg has been investigated here by means of optical microscopy, electron backscattered diffraction, shear punch test and hardness test. Results indicate that the recrystallization process along the grain boundaries consists of dynamic, metadynamic and static recrystallization, while dynamic recrystallization as the dominant mechanism gives rise to bimodal microstructures in as-extruded samples with superior properties. The recrystallized area is narrow at low amounts of alloying elements, whereas addition of higher amounts of alloying elements promotes recrystallization, expands recrystallized areas and weakens texture intensity. Moreover, it is observed that there are some optimal REs ratios promoting a partially recrystallized grain structure which in turn provides higher shear strength, hardness values, and more enhanced ductility as well as a weaker texture.

Graphic Abstract

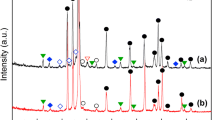

Texture intensity decreases by the increase in the amount of alloying elements

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time while they are part of our future studies.

References

W. Frank, Acta Biomater. 6, 1680–192 (2010). https://doi.org/10.1016/j.actbio.2010.02.028

A.A. Luo, A.K. Sachdev, Alloy. Fundam. Process. Prop. Appl. (2012). https://doi.org/10.1016/B978-1-84569-968-0.50012-0

B.L. Mordike, T. Ebert, Mater. Sci. Eng. A. 302, 37–45 (2001). https://doi.org/10.1016/S0921-5093(00)01351-4

S. Tekumalla, S. Seetharaman, A. Almajid, M. Gupta, Metals (Basel). 5, 1–39 (2014). https://doi.org/10.3390/met5010001

Y. Du, M. Zheng, Y. Ge, B. Jiang, M. Shen, Mater. Charact. 145, 501–506 (2018). https://doi.org/10.1016/j.matchar.2018.09.021

N. Stanford, D. Atwell, A. Beer, C. Davies, M.R. Barnett, Scr. Mater. 59, 772–775 (2008). https://doi.org/10.1016/j.scriptamat.2008.06.008

L.L. Rokhlin, Met. Sci. Heat Treat. 48, 487–490 (2006). https://doi.org/10.1007/s11041-006-0122-y

S.M. Zhu, M.A. Gibson, M.A. Easton, J.F. Nie, Scr. Mater. 63, 698–703 (2010). https://doi.org/10.1016/j.scriptamat.2010.02.005

Y. Huang, W. Gan, K.U. Kainer, N. Hort, J. Magnes. Alloy. 2, 1–7 (2014). https://doi.org/10.1016/j.jma.2014.01.005

B. Chen, X. Li, C. Lu, L. Donliang, Met. Mater. Int. 20, 489–497 (2014). https://doi.org/10.1007/s12540-014-3012-7

Z.B. Ding, Y.H. Zhao, R.P. Lu, M.N. Yuan, Z.J. Wang, H.J. Li, H. Hua, Trans. Nonferrous Met. Soc. China. 29, 722–734 (2019). https://doi.org/10.1016/S1003-6326(19)64982-4

L.B. Tonga, X. Li, D.P. Zhanga, L.R. Chenga, J. Menga, H.J. Zhanga, Mater. Charact. 92, 77–83 (2014). https://doi.org/10.1016/j.matchar.2014.03.006

B. Langelier, A.M. Nasiri, S.Y. Lee, M.A. Gharghouri, S. Esmaeili, Mater. Sci. Eng. A. 620, 76–84 (2014). https://doi.org/10.1016/j.msea.2014.09.116

G. Wang, G. Huang, X. Chen, Q. Deng, A. Tang, B. Jiang, F. Pan, Mater. Sci. Eng. A. (2017). https://doi.org/10.1016/j.msea.2017.08.036

C. Xu, S.W. Xu, M.Y. Zheng, K. Wu, E.D. Wang, S. Kamado, G.J. Wang, X.Y. Lv, J. Alloys Compd. 524, 46–52 (2012). https://doi.org/10.1016/j.jallcom.2012.02.050

X. Jin, W. Xu, D. Shan, C. Liu, Q. Zhang, Met. Mater. Int. 23, 434–443 (2017). https://doi.org/10.1007/s12540-017-6352-2

R.K. Guduru, A.V. Nagasekhar, R.O. Scattergood, C.C. Koch, K.L. Murty, Finite Element Analysis of a Shear Punch Test. Metall. Mater. Trans. 37A, 1477–1483 (2006)

B. Beausir, J.J. Fundenberger, Analysis Tools for Electron and X-ray diffraction, ATEX Software. (2017). https://www.atex-software.eu

Y.N. Wang, J.C. Huang, Mater. Chem. Phys. 81, 11–26 (2003). https://doi.org/10.1016/S0254-0584(03)00168-8

N. Stanford, M.R. Barnett, Mater. Sci. Eng. A. (2008). https://doi.org/10.1016/j.msea.2008.05.045

F.J. Humphreys, M. Hatherly, Recrystallization and Related Annealing Phenomena (Elsevier, Amsterdam, 2004)

M.R. Barnett, Mater. Sci. Eng. A. 464, 1–7 (2007). https://doi.org/10.1016/j.msea.2006.12.037

N. Stanford, Mater. Sci. Eng. A. 527, 2669–2677 (2010). https://doi.org/10.1016/j.msea.2009.12.036

X. Liu, Z. Zhang, Q. Le, L. Bao, J. Magnes. Alloy. 4, 214–219 (2016). https://doi.org/10.1016/j.jma.2016.06.002

W.Y. Wang, S.L. Shang, Y. Wang, Z.G. Mei, K.A. Darling, L.J. Kecskes, S.N. Mathaudhu, X.D. Hui, Z.K. Liu, Mater. Res. Lett. 2, 29–36 (2014). https://doi.org/10.1080/21663831.2013.858085

S.R. Agnew, M.H. Yoo, C.N. Tome, Acta Mater. (2001). https://doi.org/10.1016/S1359-6454(01)00297-X

R. Guduru, R. Scattergood, C. Koch, K. Murty, A. Nagasekhar, Metall. Mater. Trans. A 37, 1477–1483 (2006). https://doi.org/10.1007/s11661-006-0092-0

L. Gao, R.S. Chen, E.H. Han, J. Alloys Compd. 472, 234–240 (2009). https://doi.org/10.1016/j.jallcom.2008.04.049

H. Zhao, G. Qin, Y. Ren, W. Pei, D. Chen, Y. Guo, J. Alloys Compd. 509, 627–631 (2011). https://doi.org/10.1016/j.jallcom.2010.09.120

L. Kong, I.O.P. Conf, Ser. Mater. Sci. Eng. (2017). https://doi.org/10.1088/1757-899X/242/1/012026

L. Gao, R.S. Chen, E.H. Han, J. Alloys Compd. 481, 379–384 (2009). https://doi.org/10.1016/j.jallcom.2009.02.131

Acknowledgements

The authors would like to acknowledge the financial support from the Shiraz University and the Universidad Politécnica de Catalunya. This work was also supported by the research council office of Shiraz University through Grant No. 97-GR-ENG-15.

Funding

The authors declare that they received no funding for this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abbasi, Z., Ebrahimi, R. & Cabrera, J.M. Investigation on Texture Evolution and Recrystallization Aspects of Novel Mg–Zn–Gd–Y–Nd Alloys. Met. Mater. Int. 27, 3983–3992 (2021). https://doi.org/10.1007/s12540-020-00729-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00729-2