Abstract

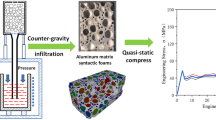

Alumina hollow spheres with a diameter range of 1–2 mm were filled in 6061 Al alloy by gravity infiltration casting to synthesize Al-matrix syntactic foams. The effects of infiltration temperature and heat treatment on microstructure, compressive properties, and energy absorption properties of the syntactic foams were studied. The results show that high quality syntactic foams could be synthesized in the infiltration temperature range 770–830 °C and the particles seamlessly bonded with the matrix. The average density and porosity of the syntactic foams were around 1.66 g/cm3 and 37.47%, respectively. The highest energy absorption capacity and specific energy absorption of the as-cast syntactic foams occurred at infiltration temperature 770 °C, reaching 41.11 MJ/m3 and 23.63 kJ/kg, respectively, while these parameters for the heat-treated samples showed the maximum values for the solution-aging treated samples, reaching 48.92 MJ/m3 and 31.36 kJ/kg respectively. Extensive literature survey is presented in this work by extracting the compressive properties of a variety of Al-matrix syntactic foams and comparing them with the results obtained in the present work. It is observed that the syntactic foams synthesized by gravity infiltration method equal or exceed the properties demonstrated by many Al-matrix syntactic foams synthesized by other methods reported in recent years. As a major advantage, the gravity infiltration method can be scaled up to industrial production level.

Similar content being viewed by others

References

Y. Hangai, H. Matsushita, R. Suzuki, S. Koyama, K. Amagai, R. Nagahiro, T. Utsunomiya, M. Matsubara, N. Yoshikawa, J. Porous Mater. 26(4), 1149–1155 (2019)

Y. Hangai, K. Takahashi, R. Nagahiro, K. Amagai, T. Utsunomiya, N. Yoshikawa, J. Porous Mater. (2019). https://doi.org/10.1007/s10934-019-00810-1

P.K. Rohatgi, N. Gupta, B.F. Schultz, D.D. Luong, JOM 63(2), 36–42 (2011)

M. Taherishargh, I.V. Belova, G.E. Murch, T. Fiedler, Mater. Sci. Eng. 635, 102–108 (2015)

L. Licitra, D.D. Luong, O.M. Strbik, N. Gupta, Mater. Des. 66, 504–515 (2015)

I.N. Orbulov, Mater. Sci. Eng. 583, 11–19 (2013)

G. Castro, S.R. Nutt, X. Wenchen, Mater. Sci. Eng. 578, 222–229 (2013)

G.A. Rivero, B.F. Schultz, J.B. Ferguson, N. Gupta, P.K. Rohatgi, J. Mater. Res. 28(17), 2426–2435 (2013)

J. Cox, D.D. Luong, C.V. Shunmugasamy, N. Gupta, M.O. Strbik, K. Cho, Metals 4(4), 1–83 (2014)

D.P. Mondal, M.D. Goel, N. Bagde, N. Jha, S. Sahu, A.K. Barnwal, Mater. Des. 57, 315–324 (2014)

S. Sahu, D.P. Mondal, J.U. Cho, M.D. Goel, M.Z. Ansari, Compos. B 160, 394–401 (2019)

Q. Zhang, Y. Lin, H. Chi, J. Chang, G. Wu, Compos. Struct. 183, 499–509 (2018)

L. Pan, Y. Yang, M.U. Ahsan, D.D. Luong, N. Gupta, A. Kumar, P.K. Rohatgi, Mater. Sci. Eng. A 731, 413–422 (2018)

G. Anbuchezhiyan, B. Mohan, D. Sathianarayanan, T. Muthuramalingam, J. Alloys Compd. 719, 125–132 (2017)

D.D. Luong, V.C. Shunmugasamy, N. Gupta, D. Lehmhus, J. Weise, J. Baumeister, Mater. Des. 66, 516–531 (2015)

Y. Lin, Q. Zhang, F. Zhang, J. Chang, G. Wu, Mater. Sci. Eng. A 696, 236–247 (2017)

C.A. Vogiatzis, A. Tsouknidas, D.T. Kountouras, S. Skolianos, Mater. Des. 85, 444–454 (2015)

S. Birla, D.P. Mondal, S. Das, N. Prasanth, A.K. Jha, A.N.C. Venkat, Trans. Indian Inst. Met. 70(7), 1827–1840 (2017)

D. Newsome, B. Schultz, J. Ferguson, P. Rohatgi, Materials 8(9), 5292 (2015)

K. Al-Sahlani, S. Broxtermann, D. Lell, T. Fiedler, Mater. Sci. Eng. A 728, 80–87 (2018)

A. Averardi, C. Cola, S.E. Zeltmann, N. Gupta, Mater. Today Commun. 24, 100964 (2020)

E. Lamanna, N. Gupta, P. Cappa, O.M. Strbik, K. Cho, J. Alloys Compd. 695, 2987–2994 (2017)

M. Omar, C. Xiang, N. Gupta, O.M. Strbik, K. Cho, Mater. Sci. Eng. 643, 156–168 (2015)

V.M. Sreekumar, R.M. Pillai, C. Pai, M. Chakraborty, J. Mater. Process. Technol. 192, 588–594 (2007)

L. Guobin, S. Jibing, G. Quanmei, W. Yuhui, J. Mater. Process. Technol. 161(3), 445–448 (2005)

S. Beroual, Z. Boumerzoug, P. Paillard, Y. Borjon-Piron, J. Alloys Compd. 784, 1026–1035 (2019)

K. Tang, Q. Du, Y. Li, Calphad 63, 164–184 (2018)

H. Yang, S. Ji, W. Yang, Y. Wang, Z. Fan, Mater. Sci. Eng. A 642, 340–350 (2015)

Y.-L. Ji, F.-A. Guo, Y.-F. Pan, Trans. Nonferrous Met. Soc. China 18(1), 126–131 (2008)

Y. Wu, J. Xiong, R. Lai, X. Zhang, Z. Guo, J. Alloys Compd. 475(1), 332–338 (2009)

B. Soni, S. Biswas, J. Porous Mater. 24(1), 29–37 (2017)

D.K. Balch, J.G. O’Dwyer, G. Davis, C.M. Cady, G. Gray, D. Dunand, Mater. Sci. Eng. 391, 408–417 (2005)

S. Broxtermann, M. Taherishargh, I.V. Belova, G.E. Murch, T. Fiedler, J. Alloys Compd. 691, 690–697 (2017)

X.F. Tao, L.P. Zhang, Y.Y. Zhao, Mater. Des. 30(7), 2732–2736 (2009)

G.H. Wu, Z.Y. Dou, D.L. Sun, L.T. Jiang, B.S. Ding, B.F. He, Scr. Mater. 56(3), 221–224 (2007)

M. Taherishargh, I.V. Belova, G.E. Murch, T. Fiedler, Mater. Sci. Eng. 604, 127–134 (2014)

B.D. Newsome, F.B. Schultz, B.J. Ferguson, K.P. Rohatgi, Materials 8(9), 1–378 (2015)

A. Daoud, J. Alloys Compd. 486(1), 597–605 (2009)

D.D. Luong, O.M. Strbik, V.H. Hammond, N. Gupta, K. Cho, J. Alloys Compd. 550, 412–422 (2013)

A. Daoud, Mater. Sci. Eng. 488(1), 281–295 (2008)

M. Taherishargh, E. Linul, S. Broxtermann, T. Fiedler, J. Alloys Compd. 737, 590–596 (2018)

B. Katona, A. Szlancsik, T. Tábi, I.N. Orbulov, Mater. Sci. Eng. 739, 140–148 (2019)

S. Sahu, M.Z. Ansari, D.P. Mondal, C. Cho, Mater. Sci. Technol. 35(7), 856–864 (2019)

A. Wright, A. Kennedy, Adv. Eng. Mater. 19(11), 1600467 (2017)

B. Zhang, Y. Lin, S. Li, D. Zhai, G. Wu, Compos. B 98, 288–296 (2016)

M. Taherishargh, M. Vesenjak, I.V. Belova, L. Krstulović-Opara, G.E. Murch, T. Fiedler, Mater. Des. 99, 356–368 (2016)

J.A. Maria, B.F. Schultz, J.B. Ferguson, N. Gupta, P.K. Rohatgi, J. Mater. Sci. 49(3), 1267–1278 (2014)

S.B. Bonabi, J.K. Khabushan, R. Kahani, A.H. Raouf, Mater. Des. 64, 310–315 (2014)

A. Daoud, Mater. Sci. Eng. 525(1), 7–17 (2009)

J. Liu, S. Yu, X. Zhu, M. Wei, Y. Luo, Y. Liu, J. Alloys Compd. 476(1), 220–225 (2009)

Acknowledgements

The authors acknowledge Youth Fund of Guangxi Key Laboratory of Processing for Non-ferrous Metal and Featured Materials (GXYSYF1806), Guangxi Natural Science Foundation (Grant No. 2016JJA160069), Nanning Scientific Research and Technology Development Program (20171005-1), Guangxi University Research Fund Project (Grant No. XJZ100343), Innovation Drive Development Foundation of Guangxi (Grant No. AA17202011), Innovation and Entrepreneurship Training Program for College Students of Guangxi University (201810593230). Jieming Wen is thanked for providing the electronic universal testing machine for compression test.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pan, L., Rao, D., Yang, Y. et al. Gravity casting of aluminum-Al2O3 hollow sphere syntactic foams for improved compressive properties. J Porous Mater 27, 1127–1137 (2020). https://doi.org/10.1007/s10934-020-00889-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-020-00889-x