Abstract

Bioleaching is suggested as a methodology with benefits in ex situ/in situ bioremediation for reducing metal contamination in dredged sediments. The process of bioleaching assisted by microorganisms in a stirred tank is widely used, among other biohydrometallurgical techniques, for the efficient extraction of metals of interest if the recovery costs of valuable metals allow it. Measurement of the mass transfer capacity of oxygen in an aerobic bioreactor is of vital importance; this factor determines the productivity of the system, since it promotes microbial growth and hence enables a bioconversion process at the mineral surface takes place. The main objective of the present research was to determine the volumetric oxygen transfer coefficient (kLa) during the manganese bioleaching process in a stirred tank reactor using silicone oil as a vector to improve the transfer of gaseous substrates. Experiments were carried out in triplicate with a 22 factorial design analyzing temperature (30 and 40 °C) and stirring speed (300 and 500 rpm). The effect of viscosity on the system was also determined by modifying the concentrations of mining waste (30, 40, and 50%), ferrous sulfate (FeSO4 · 7H2O) (2, 4, 8, and 14%), and silicone oil (0, 5, and 10%) at 0 and 24 h of mixing. The results showed an increase in the value of kLawith respect to time, from kLa(0 h, 30 °C, 500 rpm) = 8.75 s−1 to kLa(24 h, 40 °C, 500 rpm) = 18.18 s−1; ANOVA statistical analysis was performed with the Fisher and Tukey tests and showed that there were statistically significant differences.

Similar content being viewed by others

1 Introduction

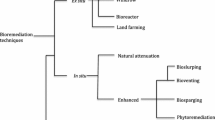

As a result of the mining activity in Mexico over decades, wastes (mine tailings) have been generated and disposed of in open areas, and the recovery of valuable components from these wastes is possible. However, if not treated properly, these wastes represent a serious pollution problem; for example, by the year 2000, between 10,000 and 600,000 metric tons of various metals, such as Cd, As, Cu, Ni, Pb, and Zn, had been reported worldwide (Mendez and Maier 2008). Bioleaching has been suggested as a methodology with benefits in ex situ/in situ bioremediation for reducing metal contamination in dredged sediments (Gu et al. 2018; Fonti et al. 2016; Rodríguez et al. 2001).

Bacterial leaching or bioleaching is the attack and solubilization of a mineral through the direct or indirect action of different microorganisms (Diao et al. 2014) due to their adaptation to the changing environment associated with these processes. Bioleaching processes result from catalysis by microorganisms during the dissolution of mineral ores as the microorganisms transfer electrons for survival purposes, and metals are released without requiring an external energy supply. In this type of process, high activation energies are not necessary; as proof, the reactions take place at low pressure and low temperature (Ghosh et al. 2016; Diao et al. 2014; Rodríguez et al. 2001; Lombardi and Garcia 1999).

As a result of related research, various applications and technologies have been developed that allow bioleaching to work under various weather conditions (humidity, temperature, precipitation, etc.) and operational conditions (pH, pulp density, residence time, particle size, mass transfer rate, etc.) at different scales (flask level, pilot plant, and industrial scale), and the extraction of valuable metals (gold and silver), basic metals (copper and iron), and even radioactive metals (uranium) has been achieved (Rana et al. 2019; Ghosh et al. 2016; Zhou et al. 2009; Acevedo 2002; Mathur et al. 2000; Salameh et al. 1999). Most of these microbiological processes are aerobic and are commonly carried out in an aqueous medium containing salts and organic substances (Ghosh et al. 2016; Govender and Gericke 2011; Liu et al. 2006; Çalik et al. 2004; Kinzler et al. 2003).

Among production processes, metallurgical leaching is used to take advantage of mining material and produce copper, gold, and silver mineral concentrates, and even radioactive metals such as uranium. On the other hand, heap leaching is a conventional process used in traditional methods for the recovery of gold and silver from minerals with low concentrations of such metals; given its relative operational and technological simplicity and low investment cost compared to other methods, heap leaching is one of the most attractive techniques for the extraction of precious metals (Rodríguez et al. 2001).

The process of leaching assisted by microorganisms in a stirred tank is widely studied and compared to other biohydrometallurgical techniques to determine the best conditions for the efficient extraction of a metal of interest (Núñez Ramírez et al. 2019; Borja et al. 2019; Wang et al. 2013; Zare Tavakoli et al. 2017; Watling 2016). Studies carried out at the laboratory level generate the necessary information to scale up a process to the industrial level and thus determine the viability of the process if the recovery costs of valuable metals allow it; this objective makes the present study valuable in terms of determining the operating conditions that allow for increased transfer of a gaseous substrate. However, bioleaching is affected by abiotic and biotic factors (climate, geology, nutrients, respiration, pH, humidity, and temperature, which are characteristics of the microorganisms present); when modified, these factors may limit or favor metabolic capacity, which determines the success and efficiency of the process.

The measurement of the oxygen mass transfer capacity in an aerobic bioreactor is of vital importance since this parameter determines the productivity of the system. Therefore, there are many empirical equations to determine the kLa coefficient, and efforts have been made to theoretically predict its value. Thus, a large number of studies have determined the importance of the characteristics of the physicochemical parameters, design, and control in the transport of the gaseous substrate during relevant processes (Garcia-Ochoa and Gomez 2004; Tobajas et al. 1999; García-Ochoa and Gómez 1998; Tyagi et al. 1998; Kawase and Hashiguchi 1996; Kawase et al. 1992; Garcia-Calvo and Letón 1991; Garcia-Calvo 1989; Kawase et al. 1987). Additionally, many projects have focused on the general characteristics of the problems of mass transfer in systems where oxygen passes from one phase to another (gas-liquid) containing microorganisms (Garcia-Ochoa and Gomez 2009; Garcia-Ochoa and Gomez 2005; Kawase et al. 1992). In aerobic processes, oxygen is a very important factor to monitor since its transfer is affected by variables such as solubility, bubble size, temperature, pressure, the properties of the liquid medium, the concentration of oxygen in the gas phase, and the force transferred by agitation (rpm), among others. Hence, a continuous supply of oxygen is essential; therefore, the oxygen transfer rate (OTR) must be known and, if possible, predicted to optimally design the operation and scale of a bioreactor. Knowing the concentration of oxygen available to the organism of interest allows determining the energy and process requirements in aeration and agitation, since oxygen is the electron acceptor (ea−). It is also important to mention that several studies have been conducted in two-phase partitioning bioreactors (TPPBs) where silicone oil is added as a nonaqueous phase (NAP) to a biological process to enhance the delivery of oxygen (a compound with low solubility in water) to microorganisms (Quijano et al. 2010). However, the present study is quite different and complex, since mineral waste (% pulp) and ferrous sulfate (% w/v) were also present in the system, in addition to silicone oil and indigenous microorganisms, which made the rheological behavior and interactions among components vary. The main objective of the present research was to determine the volumetric oxygen transfer coefficient (kLa) during the manganese bioleaching process in a stirred tank reactor-using silicone oil as a vector to improve the transfer of gaseous substrates-as well as the effect of temperature and mixing speed. Statistical analysis of the results was conducted to evaluate the interactions of the variables using the response surface method.

2 Materials and Methods

2.1 Materials

The following chemicals were purchased from the Monterrey Chemical Products Fermont Company (Monterrey, Mexico): (NH4)2SO4 (batch 541205), MgSO4 · 7H2O (batch 015216), KCl (batch 102507), K2HPO4 (batch 837101), Ca(NO3)2 (batch 004082), FeSO4 · 7H2O (batch 0000183344), and H2SO4 (batch 848346).

2.2 Experimental Phase

To estimate the volumetric mass transfer coefficient (kLa) and the influence of viscosity, temperature, and stirring speed (rpm) on that coefficient, a stirred reactor was used (BioFlo III batch/continuous fermenter, New Brunswick Scientific, Edison, N.J., USA). For this purpose, mining waste was obtained from a local company. The varied parameters included the concentration of mining waste (30, 40, and 50%, w/v), the concentration of ferrous sulfate heptahydrate (FeSO4 · 7H2O) (2, 4, 8, and 14%, w/v), the concentration of silicone oil (0, 5, and 10%, v/v), temperature (30 and 40 °C), and stirring speed (300 and 500 rpm), and measurements were performed at different mixing times (0 and 24 h).

2.3 Inoculum Seed

An isolate of a native bacterial strain from a humid area of the mine was used. It was grown in 9 K medium (Silverman and Lundgren 1959), containing 3.0 g/L (NH4)2SO4, 0.5 g/L MgSO4 · 7H2O, 0.1 g/L KCl, 0.5 g/L K2HPO4, 0.01 g/L Ca(NO3)2, and 44.22 g/L FeSO4 · 7H2O. The pH was adjusted to 2 with 2 N H2SO4, incubated at 30 °C, and stirred at 160 rpm in 500-mL Erlenmeyer flasks with baffles.

2.4 Calibration of the Dissolved Oxygen Electrode

Measurements were made using a dissolved oxygen (DO) sensor (AppliSens, Z010023526, L = 235 mm, D = 12 mm, K9GMP) with the help of a controller (B&C Electronics, OD 7685, microprocessor). Two flasks containing distilled water with 0 and 100% DO were used. (a) Nitrogen (N2) was bubbled for 20 min in one of the flasks until the electrode reading indicated the minimum concentration (0–0.05 mg/L). (b) Simultaneously, air was bubbled into the other flask to reach 100% DO (7 mg/L).

2.5 Statistical Design and Experimental Strategy

The two experimental designs were used: (a) a Box-Behnken-type surface response methodology and (b) a 22 factorial design. The Box-Behnken design was selected since three variables had to be studied: ferrous sulfate heptahydrate (FeSO4 · 7H2O), silicone oil, and mining waste; these variables represent a considerable expense in the analysis and scaling of reactors. Silicone oil was used to study whether it had a positive effect on (kLa). The 22 factorial design was selected to determine whether temperature and speed (rpm) would have a positive effect on the response of the kLa coefficient.

2.5.1 Box-Behnken Experiment

A statistical design was carried out by using Box-Behnken-type response surface methodology to evaluate the response behavior by varying the viscosity in the system; the experiments were performed in a Bioflo III batch/continuous fermenter bioreactor. The variables analyzed were % FeSO4 · 7H2O (w/v), % silicone oil (v/v), and % mining waste (w/v), and a total volume of 80% of the bioreactor capacity (4.5 L) was used. The experiment was started by adding mining waste to the bioreactor, followed by 9 K medium and then silicone oil. The reactor flanges were closed, and it was verified that the O2 and N2 inlets were not occupied by solute. The reactor was stabilized, and 200 mL of H2SO4 was added to bring the medium to the pH required for bacterial culture. Once the temperature of 30 °C was reached, the bioreactor was swept with N2, the dissolved oxygen electrode was put in place, and the concentration of ea− was monitored until it reached 0 mg/L. Once this concentration was reached, aeration at 1 volume of gas per volume of liquid per minute (VVM) was started, and the changes were measured every 10 s for 700 s—the time at which a relatively constant concentration in the system was reached.

2.5.2 22 Factorial Experiment

A complete factorial experimental design with three replicates was carried out, and temperature (°C) and stirring speed (rpm) were evaluated to observe what parameters modify kLa under “nonoptimal” conditions for the microorganisms and the coefficient behavior under limiting conditions. In these experiments, the concentrations of mining waste and ferrous sulfate were kept constant, and no silicone oil was added. Mining waste sample = 450 g; 9 K media = 4.05 L; ferrous sulfate = 67.5 ppm; and sulfuric acid = 100 mL.

To operate the reactor, mining waste and 9 K medium were added; it was verified that there were no obstructions in the oxygen and nitrogen supply ducts. The reactor flanges were closed, the motor was put in place, the temperature was set, and the set point was adjusted according to the experimental run (30 or 40 °C; 300 or 500 rpm). The reactor was closed, and 100 mL of H2SO4 was carefully added. When the temperature reached the set point, N2 was added. Measurements were made every 10 s for 12 min, at which time a constant concentration of O2 was reached.

2.6 Estimate of kLa: Gassing-out Method

The estimation of kLa in bioreactors is essential to establish aeration efficiency and quantify the effects of operating variables on the supply of dissolved oxygen. Some methods have been developed to determine the flow of oxygen transfer in bioreactors (Galaction et al. 2004). Some of these methods are applied to other compounds in the same way, but others are specific to the measurement of oxygen transfer.

The mass balance for dissolved oxygen in the liquid phase with ideal mixing can be established according to eq. 1 as follows:

where \( \frac{dC}{dt} \)is the accumulation of the oxygen flow in the liquid phase, OTR represents the flow of oxygen transfer from the gas to the liquid, and OUR is the oxygen utilization or consumption rate by microorganisms; the last term can be expressed by the following product (eq. 2):

where \( {q}_{O_2} \) is the specific oxygen consumption rate of the microorganisms (O2 demand) and Cx is the biomass concentration.

The method used to estimate kLa in the present work was the biological method, which measures the concentration of dissolved oxygen in the medium by oxygen absorption or desorption. After a step change in the inlet gas concentration, the dynamic change in the concentration of dissolved oxygen was analyzed. Only the dynamics of the liquid phase are considered in this work, assuming a completely mixed system, and the evolution of oxygen concentration is modeled by eq. 3.

where C∗ is the concentration in equilibrium with the gas phase (mg/L) and CL is the concentration at different time intervals (mg/L).

If OUR = 0, integration results in eq. 4:

The biological absorption technique consists of the elimination of oxygen in the liquid phase, for example, by means of nitrogen bubbling or the addition of sodium sulfate, until the oxygen concentration is equal to zero. Then, the liquid is brought back into contact with air, and the variation (increase) in oxygen concentration over time is measured. The biological desorption technique consists of supplying air until the concentration of dissolved oxygen saturation is reached. Then, nitrogen is introduced into the tank, decreasing the concentration of dissolved oxygen, and values are recorded as a function of time. Under these conditions \( \left({t}_1=0;{C}_1={C}_{L_0}\right), \) eq. 4 can be expressed as follows:

On the other hand, when oxygen has been removed from the system (by bubbling nitrogen) and oxygen is fed to the system again (t1 = 0; C1 = 0), eq. 4 can be expressed as follows:

where \( {C}_g^{\ast } \) is the concentration of oxygen saturation over time and it is a function of the solid fraction (mineral waste, % pulp). Equations 5 and 6 describe the course of dissolved oxygen when restarting aeration or when oxygen is removed from the system; in both cases, kLa can be determined from the slope of the graph of Ln f (CL) vs time.

This technique is interesting for the study of the influence of operational conditions on the volumetric mass transfer coefficient, and it is widely used, as reported in the literature (García-Ochoa and Gómez 1998). Nevertheless, it is necessary to consider the response time tr, which is a critical parameter for the precise determination of oxygen concentration. In the present project, the response of the electrode is omitted since it is negligible, being 1 s. Therefore, the electrode response does not substantially affect the results of the estimation.

Two process variables were selected, temperature and stirring speed (rpm), due to their effect on system costs. The concentration of the energy source (FeSO4 · 7H2O) in the culture medium, the amount of mining waste, and the volume of silicone oil were varied. The amount of mining waste directly influences the recovery of valuable metals, the removal of manganese, and the transfer of oxygen during the process, while the use of silicone oil modifies the viscosity of the system, which influences the transfer of oxygen.

To estimate kLa, nitrogen was bubbled into the bioreactor, and the DO electrode was placed in contact with the heterogeneous mixture until a concentration of 0 mg/L was reached. The O2 feed valve was then opened, and the volume of gas per volume of liquid per minute (VVM), temperature (30 and 40 °C), and corresponding stirring speed (300 and 500 rpm) were maintained for each experimental run. Measurements of variations in concentration were made at intervals of 10 s until a constant value was reached. The pH was adjusted at the beginning of the process (2.0 ± 0.2) with concentrated H2SO4 to ensure consortium survival.

3 Results and Discussion

3.1 Effect of Mining Waste Concentration on kLa

Analysis of the Box-Behnken design response variables showed an increase in the solubility of O2 and in the transfer rate during the measurement of kLa at 8% ferrous sulfate, 5% silicone oil, and 40% mining waste, as seen in Fig. 1; above 90% reliability was obtained in each of two replicas.

The results demonstrate a directly proportional relationship between the aeration and agitation processes and an inversely proportional relationship between kLa and the concentration of the mining waste; this phenomenon is adequately represented in the response surface and contour plots (Fig. 2). The model parameters are presented in Table 1, demonstrating the negative impact from the principal effect factors and the positive effects from the interactions. In addition, it was observed that even if the concentration of waste was increased, the presence of silicone oil (> 5%) maintained the solubility of O2 in the medium (> 20 mg/L), generating a positive effect on the homogeneity of the system in terms of aeration and mixing. This effect would have a direct impact on reducing the operational costs of bioleaching in a stirred tank since the mass transfer of gas to the pulp is improved by dispersion in the gaseous substrate. In the same way, a higher concentration of mining waste and higher addition of silicone oil, the tendency for kLa to decrease could be the same as that at a lower concentration of silicone oil; eliminating these unnecessary expenses would decrease the cost of the process required to handle a higher concentration of ore.

The interaction between the concentration of mining waste (solids) and silicone oil can be seen in Fig. 3, highlighting the following: (i) the use of oil promoted gas solubility even with an increase in the solid phase (mining waste). (ii) the decrease in kLa was inversely proportional to the addition of silicone oil, highlighting in an important way the interactions between waste concentrations of 40 and 45%, values that generate a negative effect on the solubility of the gaseous substrate during operation. (iii) An increase in the concentration of silicone oil did not favor mass transfer through the interface; however, the amount of oil did drastically decrease the drop in kLa at higher percentages of mining waste in pulp concentrations of > 50%.

Interaction graph of the factors analyzed in the Box-Behnken design (sulfate, silicone oil, and mining waste) and their effect on kLa (1 VVM, 300 rpm, and 30 °C). The blue lines indicate when the factor on the right axis is at its high level, and the red lines indicate when it is at its low level. kLa behavior at the high and low values of the experimental design: Sulfate (2 and 14%), silicone oil (0 and 10%), and mining waste (30 and 50%); see Table 1

Furthermore, the use of the same silicone oil concentration (5–10%) at higher concentrations of pulp or mining waste (> 50%) could improve the tendency for the drop in kLa to decrease or maintain a minimum concentration of the gaseous substrate, enabling the microorganisms to carry out the bioleaching process. In this way, operational benefits could be obtained, since it has been shown that bacteria can perform catalytic functions under microaerobic conditions (Ehrlich 1987; Toro et al. 1993; Vegliò et al. 1997); therefore, the oxygen requirements in these conditions, where the solubility of the gaseous substrate would be at a minimum but constant concentration due to the effect of the transfer vector (silicone oil), would help increase kLa during material processing (Couillard and Zhu 1992).

3.2 Effect of rpm and Temperature on the System at 0 and 24 H

The concentrations of dissolved O2 at the beginning and end of the process differed from the values obtained from kLa with respect to mixing time (0 and 24 h). This difference is evident since the mixing time has a strong influence on particle interactions due to redox processes caused by the metabolism of bacteria. The factor levels at which higher kLa values were obtained were (i) 30 °C and 500 rpm at 0 h and (ii) 40 °C and 500 rpm at 24 h.

These results demonstrate that the effect of the stirring speed is proportional to the response of kLa. The temperature acts inversely at the beginning (0 h) because there is not enough flow interaction in the heterogeneous reaction; in addition, it has been reported that gaseous substrates decrease in response to increased temperature (Lee 2017).

The response surface was obtained from the factorial design results (Fig. 4), where it can be seen that the temperature presents normal behavior in terms of solubility; that is, at a lower temperature, the amount of dissolved oxygen will be greater, and its transfer will increase as well. The highest kLa values were found at the highest mixing speed. Therefore, it can be concluded from this plot that if a greater amount of dissolved oxygen is desired for the proliferation of microorganisms, it is necessary to maintain conditions with a high stirring speed and low temperature for fast data collection times (at 0 h). According to the results in Table 2, the differences that affect the responses are very evident at the beginning of the process, as increasing temperature and rpm are proportional to kLa; however, at the same time, as temperature and speed begin to increase, this possible interaction moves further away. However, within the limits, there is no interaction between the variables, as can be clearly seen in Fig. 5.

The behavior at 24 h generated a higher kLa value (Fig. 5, right). On the response surface plot, it can be seen that the kLavalues are obviously higher, indicating that mixing time has a substantial influence. It may not take 24 h to reach maximum interaction; however, for the purposes of this work, this effect was analyzed.

4 Conclusions

-

The experiments carried out support the notion that the main effects of temperature, stirring speed (rpm), viscosity, and mixing time can generate the most significant changes in the transfer of O2. There is inversely proportional temperature behavior with respect to kLa and directly proportional behavior for stirring speed (rpm) with respect to kLa.

-

Judging by the parallel trend of the lines of interaction, the tendency of both lines to change at longer times will be the same. The stirring speed (rpm) plays a fundamental role, leading to better O2 transfer values. However, increasing rpm decreases microbial growth and generates vortices, which in turn hinder the rate of oxygen transfer between the gas and liquid phases.

-

It is important to mention that a higher volumetric transfer coefficient does not necessarily mean an ideal aerobic environment for microorganisms since the conditions evaluated in this factorial design were intended to create a difficult environment for the development of the microbial consortium. This relationship assumes that the temperature changes in the target process region are very abrupt and can generate changes in solubility and affect the amount of O2 that can be transferred. Therefore, one suggestion would be to analyze the process at wider temperature ranges and powers as well. The resulting analysis from the perspective of not only dissolved oxygen but also oxygen consumed (OUR) and power consumed would yield an even clearer vision of necessary inputs, project viability, and scaling with respect to a mixed batch system.

Additionally, precision in kLa estimation is important, as mentioned by Quijano et al. (2010), especially from a scale-up point of view. They suggest that the power input per unit volume (Pg/V) should be considered as a parameter that better describes the effect of the addition of NAP, such as the vector silicone oil in this study, on kLa than does the impeller speed. For the present study, (Pg/V) was not calculated because of the differences in the system that prevented range values form being compared. Most studies consider two-phase or multiphase liquid systems, and fractions are given in volume/volume (v/v) relationships. In this research, different additional fractions (mineral waste and ferrous sulfate) were included in the weight/volume (w/v) relationship, in addition to silicone oil and native microorganisms, which made the rheological behavior and interactions among factors vary.

It is quite important to consider this point of view for further experimentation to determine (Pg/V) in multiphase systems with solid fractions and to evaluate the influence on the estimation of kLa in these systems. On the other hand, due to the metabolic processes of indigenous microorganisms, the system (solid/liquid/vector fractions) generates an effect on viscosity that would change with respect to time, as reported by Núñez Ramírez et al. (2019) and Kinzler et al. (2003). After a certain time, bacterial proliferation would generate a change in the mineral surface, in addition to the production of extracellular polymeric substances (EPS) that would influence the rheological properties of the system.

References

Acevedo, F. (2002). Present and future of bioleaching in developing countries. Electronic Journal of Biotechnology, 5(2), 18–19. https://doi.org/10.2225/vol5-issue2-fulltext-10.

Borja, D., Nguyen, K. A., Silva, R. A., Ngoma, E., Petersen, J., Harrison, S. T. L., Park, J. H., & Kim, H. (2019). Continuous bioleaching of arsenopyrite from mine tailings using an adapted mesophilic microbial culture. Hydrometallurgy, 187, 187–194. https://doi.org/10.1016/j.hydromet.2019.05.022.

Çalik, P., Yilgör, P., Ayhan, P., & Demir, A. (2004). Oxygen transfer effects on recombinant benzaldehyde lyase production. Chemical Engineering Science, 59, 5075–5083. https://doi.org/10.1016/j.ces.2004.07.070.

Couillard, D., & Zhu, S. (1992). Bacterial leaching of heavy metals from sewage sludge for agricultural application. Water, Air, and Soil Pollution, 63, 67–80. https://doi.org/10.1007/BF00475622.

Diao, M., Taran, E., Mahler, S., & Nguyen, A. (2014). A concise review of nanoscopic aspects of bioleaching bacteria–mineral interactions. Advances in Colloid and Interface Science, 212, 45–63. https://doi.org/10.1016/j.cis.2014.08.005.

Ehrlich, H. L. (1987). Manganese oxide reduction as a form of anaerobic respiration. Geomicrobiology Journal, 5(3–4), 423–431. https://doi.org/10.1080/01490458709385977.

Fonti, V., Dell’Anno, A., & Beolchini, F. (2016). Does bioleaching represent a biotechnological strategy for remediation of contaminated sediments? Science of The Total Environment, 563–564, 302–319. https://doi.org/10.1016/j.scitotenv.2016.04.094.

Galaction, A. I., Cascaval, D., Oniscu, C., & Turnea, M. (2004). Prediction of oxygen mass transfer coefficients in stirred bioreactors for bacteria, yeasts and fungus broths. Biochemical Engineering Journal, 20(1), 85–94. https://doi.org/10.1016/j.bej.2004.02.005.

Garcia-Calvo, E., & Letón, P. (1991). A fluid dynamic model for bubble columns and airlift reactors. Chemical Engineering Science, 46(11), 2947–2951. https://doi.org/10.1016/0009-2509(91)85164-S.

Garcia-Calvo, E. (1989). A fluid dynamic model for airlift loop reactors. Chemical Engineering Science, 44(2), 321–323. https://doi.org/10.1016/0009-2509(89)85068-7.

Garcia-Ochoa, F., & Gomez, E. (2009). Bioreactor scale-up and oxygen transfer rate in microbial processes: an overview. Biotechnology Advances, 27(2), 153–176. https://doi.org/10.1016/j.biotechadv.2008.10.006.

Garcia-Ochoa, F., & Gomez, E. (2005). Prediction of gas-liquid mass transfer coefficient in sparged stirred tank bioreactors. Biotechnology and Bioengineering, 92(6), 761–772. https://doi.org/10.1002/bit.20638.

Garcia-Ochoa, F., & Gomez, E. (2004). Theoretical prediction of gas–liquid mass transfer coefficient, specific area and hold-up in sparged stirred tanks. Chemical Engineering Science, 59(12), 2489–2501. https://doi.org/10.1016/j.ces.2004.02.009.

García-Ochoa, F., & Gómez, E. (1998). Mass transfer coefficient in stirred tank reactors for xanthan gum solutions. Biochemical Engineering Journal, 1, 1–10. https://doi.org/10.1016/S1369-703X(97)00002-8.

Ghosh, S., Mohanty, S., Akcil, A., Sukla, L. B., & Das, A. P. (2016). A greener approach for resource recycling: manganese bioleaching. Chemosphere, 154, 628–639. https://doi.org/10.1016/j.chemosphere.2016.04.028.

Govender, Y., & Gericke, M. (2011). Extracellular polymeric substances (EPS) from bioleaching systems and its application in bioflotation. Minerals Engineering, 24(11), 1122–1127. https://doi.org/10.1016/j.mineng.2011.02.016.

Gu, T., Rastegar, S. O., Mousavi, S. M., Li, M., & Zhou, M. (2018). Advances in bioleaching for recovery of metals and bioremediation of fuel ash and sewage sludge. Bioresource Technology, 261, 428–440. https://doi.org/10.1016/j.biortech.2018.04.033.

Kawase, Y., & Hashiguchi, N. (1996). Gas—liquid mass transfer in external-loop airlift columns with newtonian and non-newtonian fluids. The Chemical Engineering Journal and the Biochemical Engineering Journal, 62(1), 35–42. https://doi.org/10.1016/0923-0467(95)03049-2.

Kawase, Y., Halard, B., & Moo-Young, M. (1992). Liquid-phase mass transfer coefficients in bioreactors. Biotechnology and Bioengineering, 39(11), 1133–1140. https://doi.org/10.1002/bit.260391109.

Kawase, Y., Halard, B., & Moo-Young, M. (1987). Theoretical prediction of volumetric mass transfer coefficients in bubble columns for Newtonian and non-Newtonian fluids. Chemical Engineering Science, 42(7), 1609–1617. https://doi.org/10.1016/0009-2509(87)80165-3.

Kinzler, K., Gehrke, T., Telegdi, J., & Sand, W. (2003). Bioleaching - a result of interfacial processes caused by extracellular polymeric substances (EPS). Hydrometallurgy, 71(1–2), 83–88. https://doi.org/10.1016/S0304-386X(03)00176-2.

Lee, J. (2017). Development of a model to determine mass transfer coefficient and oxygen solubility in bioreactors. Heliyon, 3(2), e00248. https://doi.org/10.1016/j.heliyon.2017.e00248.

Liu, Y. S., Wu, J. Y., & Ho, K. P. (2006). Characterization of oxygen transfer conditions and their effects on Phaffia rhodozyma growth and carotenoid production in shake-flask cultures. Biochemical Engineering Journal, 27(3), 331–335. https://doi.org/10.1016/j.bej.2005.08.031.

Lombardi, A. T., & Garcia, O. (1999). An evaluation into the potential of biological processing for the removal of metals from sewage sludges. Critical Reviews in Microbiology, 25(4), 275–288. https://doi.org/10.1080/10408419991299239.

Mathur, A. K., Viswamohan, K., Mohanty, K. B., Murthy, V. K., & Seshadrinath, S. T. (2000). Uranium extraction using biogenic ferric sulfate a case study on quartz chlorite ore from Jaduguda, Singhbhum Thrust Belt (STB), Bihar, India. Minerals Engineering, 13(5), 575–579. https://doi.org/10.1016/S0892-6875(00)00037-6.

Mendez, M. O., & Maier, R. M. (2008). Phytoremediation of mine tailings in temperate and arid environments. Reviews in Environmental Science and Bio/Technology, 7(1), 47–59. https://doi.org/10.1007/s11157-007-9125-4.

Núñez Ramírez, D. M., Ramírez Torres, L. R., Medina Torres, L., Calderas, F., González Lozano, M. A., Ponce Peña, P., Fierros Romero, G., & Manero, O. (2019). A rheological study of the bioleaching process of an iron ore for the elimination of gangue minerals. Minerals Engineering, 144, 106,023, 1–10. https://doi.org/10.1016/j.mineng.2019.106023.

Quijano, G., Chávez-Ávila, R., Muñoz, R., Thalasso, F., & Ordaz, A. (2010). KLa measurement in two-phase partitioning bioreactors: new insights on potential errors at low power input. Journal of Chemical Technology & Biotechnology, 85(10), 1407–1412. doi: 10.1002/jctb.2460

Rana, S., Mishra, P., & Wahid, Z. ab, Thakur, S., Pant, D., & Singh, L. (2019). Microbe-mediated sustainable bio-recovery of gold from low-grade precious solid waste: a microbiological overview. Journal of Environmental Sciences., 89, 47–64. https://doi.org/10.1016/j.jes.2019.09.023.

Rodríguez, Y., Blázquez, M. L., Ballester, A., González, F., & Muñoz, J. A. (2001). La biolixiviación al comienzo del siglo XXI. Revista de Metalurgia, 37, 616–627. https://doi.org/10.3989/revmetalm.2001.v37.i5.528.

Salameh, M., Zcengiz, G., Atalay, Ü., Zbayoglu, G., & Alaeddinoglu, N. G. (1999). Enhanced recovery of silver from Artvin-Kafkasör ore by microbial treatment. Process Metallurgy, 9, 493–499. https://doi.org/10.1016/S1572-4409(99)80050-9.

Silverman, M. P. & Lundgren, D. G. (1959). Studies on the chemoautotrophic iron bacterium Ferrobacillus ferrooxidans II: Manometric Studies. Journal of Bacteriology, 78(3), 326–331. PMCID: PMC290544.

Tobajas, M., García-Calvo, E., Siegel, M. H., & Apitz, S. E. (1999). Hydrodynamics and mass transfer prediction in a three-phase airlift reactor for marine sediment biotreatment. Chemical Engineering Science, 54(21), 5347–5354. https://doi.org/10.1016/S0009-2509(99)00262-6.

Toro, L., Vegliò, F., Terreri, M., Ercole, C., & Lepidi, A. (1993). Manganese bioleaching from pyrolusite: Bacterial properties reliable for the process. FEMS Microbiology Reviews, 11(1–3), 103–108. https://doi.org/10.1111/j.1574-6976.1993.tb00273.x

Tyagi, R. D., Sreekrishnan, T. R., Blais, J. F., Surampalli, R. Y., & Campbell, P. G. C. (1998). Effect of dissolved oxygen on sludge acidification during the SSDML-process. Water, Air, and Soil Pollution, 102, 139–155. https://doi.org/10.1023/A:1004986518555.

Vegliò, F., Beolchini, F., Gasbarro, A., Toro, L., Ubaldini, S., & Abbruzzese, C. (1997). Batch and semi-continuous tests in the bioleaching of manganiferous minerals by heterotrophic mixed microorganisms. International Journal of Mineral Processing, 50(4), 255–273. https://doi.org/10.1016/S0301-7516(97)00044-6.

Wang, J., Zhao, H. B., Zhuang, T., Qin, W. Q., Zhu, S., & Qiu, G. Z. (2013). Bioleaching of Pb-Zn-Sn chalcopyrite concentrate in tank bioreactor and microbial community succession analysis. Transactions of Nonferrous Metals Society of China, 23, 3758–3762. https://doi.org/10.1016/S1003-6326(13)62926-X.

Watling, H. (2016). Microbiological advances in biohydrometallurgy. Minerals, Special Issue Biotechnologies and Mining, 6 (2) 49, 1–19, https://doi.org/10.3390/min6020049

Zare Tavakoli, H., Abdollahy, M., Ahmadi, S. J., & Khodadadi Darban, A. (2017). Kinetics of uranium bioleaching in stirred and column reactors. Minerals Engineering, 111, 36–46. https://doi.org/10.1016/j.mineng.2017.06.003.

Zhou, H. B., Zeng, W. M., Yang, Z. F., Xie, Y. J., & Qiu, G. Z. (2009). Bioleaching of chalcopyrite concentrate by a moderately thermophilic culture in a stirred tank reactor. Bioresource Technology, 100(2), 515–520. https://doi.org/10.1016/j.biortech.2008.06.033.

Funding

This research was funded by Tecnológico Nacional de México (TecNM) - Instituto Tecnológico de Durango (ITD) and a master’s scholarship awarded by the Consejo Nacional de Ciencia y Tecnología (CONACYT).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zazueta-Álvarez, D.E., Martínez-Prado, M.A., Rosas-Flores, W. et al. Response Surface Methodology Analysis of the Effect of the Addition of Silicone Oil on the kLa Coefficient in the Bioleaching of Mine Tailings. Water Air Soil Pollut 231, 237 (2020). https://doi.org/10.1007/s11270-020-04573-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-020-04573-3