Abstract

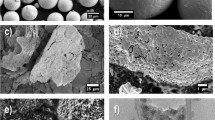

In this study, we have analyzed the formation mechanisms and processing-microstructure relationships for Al/TiC metal matrix nanocomposites produced in situ via thermite-assisted (e.g., CuO) self-propagating high-temperature synthesis (SHS). Al/TiC composites were created by reacting Al-Ti-C-CuO pellets in an Al melt using a wide variety of processing conditions (e.g., precursor powder amounts, bulk melt temperature, precursor powder size, pellet packing method). As-cast composites were visualized using both 2D (SEM) and 3D (TXM) microscopy techniques, to study TiC particle and secondary precipitate (e.g., Al3Ti) characteristics at the nanoscale. SHS-produced samples reveal complex microstructures consisting of individual and clustered TiC particles, elongated Al3Ti intermetallics, and C-rich regions surrounded by TiC. Based on a thermodynamic analysis and our microstructural observations, we propose three dominant TiC formation pathways, each resulting in a distinct microstructural signature. Finally, we utilize multivariate statistics (canonical correlations) on the full breadth of imaging data to infer the dominant processing variables (i.e., amount of CuO and C) that most strongly influence TiC particle characteristics and the final composite microstructure. We also discuss how the dominant processing variables relate to the proposed formation pathways and how they may inform the rational design of future composites produced via thermite-assisted SHS.

Similar content being viewed by others

Notes

We create two separate canonical variates (denoted as \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {Y}_{1} \) and \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {Y}_{2} \)) in order to avoid the problem of multicollinearity[50] between the dependent variables.

References

1. R. Geng, F. Qiu, Q.C. Jiang: Adv. Eng. Mater., 2018, vol. 20, pp. 1-13.

2. E.D. Moor, A. Luo, D.K. Matlock, J.G. Speer, A. Taub: Annu. Rev. Mater. Res, 2000, vol. 49, pp. 1-33.

3. A. Mortensen, J. Llorca: Annu. Rev. Mater. Res, 2010, vol. 40, pp. 243-270.

4. A.V. Muley, S. Aravindan, I.P. Singh: Manuf. Rev., 2015, vol. 2, pp. 15-15.

5. S.L. Pramod, S.R. Bakshi, B.S. Murty: J. Mater. Eng. Perform., 2015, vol. 24, pp. 2185-2207.

6. D.K. Das, P.C. Mishra, S. Singh, S. Pattanaik: Int. J. Mech. Mater. Eng., 2014, vol. 9, pp. 1-15.

7. J. Hashim, L. Looney, M.S.J. Hashmi: J. Mater. Process. Technol., 2001, vol. 119, pp. 324-328.

8. B.S.S. Daniel, V.S.R. Murthy, G.S. Murty: J. Mater. Process. Technol., 1997, vol. 68, pp. 132-155.

9. Y.H. Cho, J.M. Lee, S.H. Kim: Metall. Mater. Trans. A, 2014, vol. 45, pp. 5667-5678.

10. I. Anza, M.M. Makhlouf: Metall. Mater. Trans. B, 2018, vol. 49, pp. 466-480.

11. C. Borgonovo, M.M. Makhlouf: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 5125-5135.

C.H. Henager, J.L. Brimhall, L.N. Brush: Mater. Sci. Eng., A, 1995, vol. 195, pp. 65-74.

13. R. Radhakrishnan, S.B. Bhaduri, C.H. Henager: Adv. PM Part., 1995, vol. 3, pp. 1-9.

14. M. Backhaus-Riccoult, H. Schmalzried: Ber. Bunsenges. Phys. Chem., 1985, vol. 89, pp. 1323-1330.

15. M. Martin, H. Schmalzried: Ber. Bunsenges. Phys. Chem., 1985, vol. 89, pp. 124-130.

S.-B. Li, J.-X. Xie, L.-Y. Zhang, L.-F. Cheng: Mater. Sci. Eng. A, 2004, vol. 381, pp. 51-56.

17. A. Zhou, C.-a. Wang, Z. Ge, L. Wu: J. of Mater. Sci. Lett., 2001, vol. 20, pp. 1971-1973.

18. Y. Bai, X. He, Y. Li, C. Zhu, S. Zhang: J. Mater. Res., 2009, vol. 24, pp. 2528-2535.

19. R.F. Shyu, C.T. Ho: J. Mater. Process. Technol., 2006, vol. 171, pp. 411-416.

20. C. Wang, H. Gao, Y. Dai, X. Ruan, J. Shen, J. Wang, B. Sun: J. Alloys Compd., 2010, vol. 490, pp. 2009-2011.

21. Y.H. Cho, J.M. Lee, S.H. Kim: Metall. Mater. Trans. A, 2015, vol. 46, pp. 1374-1384.

X.C. Tong, H.S. Fang: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 875-891.

23. E. Zhang, S. Zeng, B. Yang, Q. Li, M. Ma: Metall. Mater. Trans. A, 1999, vol. 30, pp. 1147-1151.

I. Gotman, M.J. Koczak, E. Shtessel: Mater. Sci. Eng. A, 1994, vol. 187, pp. 189-199.

V. De Andrade, A. Deriy, M.J. Wojcik, D. Gürsoy, D. Shu, K. Fezzaa, F. De Carlo: Nanoscale 3D imaging at the Advanced Photon Source (SPIE, 2016). Accessed 20 August 2019.

26. C.S. Kaira, V. De Andrade, S.S. Singh, C. Kantzos, A. Kirubanandham, F. De Carlo, N. Chawla: Adv. Mater., 2017, vol. 29, pp. 1-8.

27. J.H. Friedman, J.L. Bentley, R.A. Finkel: ACM Trans. Math. Software, 1976, vol. 1549, pp. 1-38.

28. R. Keinan, H. Bale, N. Gueninchault, E.M. Lauridsen, A.J. Shahani: Acta Mater., 2018, vol. 148, pp. 225-234.

A.J. Shahani, X. Xiao, K. Skinner, M. Peters, P.W. Voorhees: Mater. Sci. Eng. A, 2016, vol. 673, pp. 307-320.

30. D. Gürsoy, F. De Carlo, X. Xiao, C. Jacobsen: J. Synchrotron Radiat., 2014, vol. 21, pp. 1188-1193.

B.A. Dowd, G.H. Campbell, R.B. Marr, V.V. Nagarkar, S.V. Tipnis, L. Axe, D.P. Siddons: in Dev. X-Ray Tomogr. II Conf. Proc., 1999, pp. 224–36.

32. D.M. Pelt, V. De Andrade: Adv. Struct. Chem. Imaging, 2017, vol. 2, pp. 1-14.

33. Y.-H. Cho, J.-M. Lee, H.-J. Kim, J.-J. Kim, S.-H. Kim: Met. Mater. Int., 2013, vol. 19, pp. 1109-1116.

K. Lee, D.S. Stewart, M. Clemenson, N. Glumac, C. Murzyn: AIP Conf. Proc., 2017, pp. 1–4.

35. P.C. Maity, P.N. Chakraborty, S.C. Panigrahi: Matt. Lett., 1997, vol. 30, pp. 147-151.

S.H. Fischer, M.C. Grubelich: 32nd AIAA/ASME/SAE/ASEE Joint Propul. Conf. Proc., 1996, pp. 1–13.

D.S. Stewart: AIP, 2017, pp. 1–4.

38. R.A. Rapp, X. Zheng: Metall. Trans. A, 1991, vol. 22, pp. 3071-3075.

39. N. Samer, J. Andrieux, B. Gardiola, N. Karnatak, O. Martin, H. Kurita, L. Chaffron, S. Gourdet, S. Lay, O. Dezellus: Composites Part A, 2015, vol. 72, pp. 50-57.

40. H.Y. Wang, Q.C. Jiang, X.L. Li, J.G. Wang: Scr. Mater., 2003, vol. 48, pp. 1349-1354.

41. Q.C. Jiang, H.Y. Wang, Y.G. Zhao, X.L. Li: Mater. Res. Bull., 2005, vol. 40, pp. 521-527.

42. V.V. Dalvi, A.K. Suresh: AIChE J., 2011, vol. 57, pp. 1329-1338.

A. Banerji, W. Reif: Metall. Trans. A, 1986, vol. 17A, pp. 2127-2137.

44. M.E. Fine, J.G. Conley: Metall. Trans. A, 1989, vol. 21A, pp. 2609-2610.

45. S. Chowdhury, K. Sullivan, N. Piekiel, L. Zhou, M.R. Zachariah: J. Phys. Chem. C, 2010, vol. 114, pp. 9191-9195.

46. N. Frage, N. Frumin, L. Levin, M. Polak, M.P. Dariel: Metall. Mater. Trans. A, 1998, vol. 29, pp. 1341-1345.

47. Z.W. Liu, Q. Han, J.G. Li: Metall. Mater. Trans. A, 2012, vol. 43, pp. 4460-4463.

48. V.T. Witusiewicz, B. Hallstedt, A.A. Bondar, U. Hecht, S.V. Sleptsov, T.Y. Velikanova: J. Alloys Compd., 2015, vol. 623, pp. 480-496.

U.R. Kattner, J.C. Lin, Y.A. Chang: Metall. Trans. A, 1992, vol. 23A, pp. 2081-2090.

J.F. Hair, Jr., W.C. Black, B.J. Babin, R.E. Anderson: Multivariate Data Analysis, 2014.

51. A.A.A. Kuylen, T.M.M. Verhallen: J. Econ. Psycho., 1981, vol. 1, pp. 217-237.

52. A. Lawrence, J.M. Rickman, M.P. Harmer, A.D. Rollett: Acta Mater., 2016, vol. 103, pp. 681-687.

53. V. Uurtio, J.M. Monteiro, J. Kandola, J. Shawe-Taylor, D. Fernandez-Reyes, J. Rousu: ACM Comput. Surv., 2017, vol. 50, pp. 1-33.

54. A. Sherry, R.K. Henson: J. Pers. Assess., 2010, vol. 3891, pp. 37-41.

55. K.E. Muller: Am. Stat., 1982, vol. 36, pp. 342-354.

56. J.M. Rickman, Y. Wang, A.D. Rollett, M.P. Harmer, C. Compson: npj Comput. Mater., 2017, vol. 3, pp. 1-5.

57. R.C. MacCallum, K.F. Widaman, S. Zhang, S. Hong: Psychol. Methods, 1999, vol. 4, pp. 84-99.

58. A.K. Chaubey, S. Scudino, N.K. Mukhopadhyay, M.S. Khoshkhoo, B.K. Mishra, J. Eckert: J. Alloys Compd., 2012, vol. 536, pp. S134-S137.

Z. Wang, M. Song, C. Sun, Y. He: Mater. Sci. Eng. A, 2011, vol. 528, pp. 1131-1137.

60. J. Chen, C. Bao, Y. Ma, Z. Chen: J. Alloys Compd., 2017, vol. 695, pp. 162-170.

B.M. Tyson, R.K. Abual-rub, A. Yazdanbakhsh, Z. Grasley: Composites B 2011, vol. 42, pp. 1395-1403.

62. H. Shimazaki, S. Shinomoto: J. Comput. Neurosci., 2010, vol. 29, pp. 171-182.

63. I. González, S. Déjean, P.G.P. Martin, A. Baccini: J. Stat. Software, 2008, vol. 23, pp. 1-14.

64. A. Paknia, A. Pramanik, A.R. Dixit, S. Chattopadhyaya: J. Mater. Eng. Perform., 2016, vol. 25, pp. 4444-4459.

65. L. Banks-Sills, V. Leiderman, D. Fang: Compos. Part B-Eng., 1997, vol. 28, pp. 465-481.

66. V.A. Romanova, R.R. Balokhonov, S. Schmauder: Acta Mater., 2009, vol. 57, pp. 97-107.

67. S. Jin, P. Shen, D. Zhou, Q. Jiang: Cryst. Growth Des., 2012, vol. 12, pp. 2814-2824.

68. S. Jin, P. Shen, Q. Lin, L. Zhan, Q. Jiang: Cryst. Growth Des., 2010, vol. 10, pp. 1590-1597.

B.-X. Dong, H.-Y. Yang, F. Qiu, Q. Li, S.-L. Shu, B.-Q. Zhang, Q. Jiang: Mater. Design, 2019, vol. 181, pp. 107951-107951.

70. D. Zhang, H. Liu, L. Sun, F. Bai, Y. Wang, J. Wang: Crystals, 2017, vol. 7, pp. 1-12.

71. L. Arnberg, L. Bäckerud, H. Klang: Met. Technol., 1982, vol. 9, pp. 7-13.

D.H. Stohn, L.M. Hogan: J. Cryst. Growth, 1979, vol. 46, pp. 387-398.

73. M.S. Lee, B.S. Terry: Mater. Sci. Tech., 1991, vol. 7, pp. 608-612.

74. V. Auradi, S.A. Kori: J. Alloys Compd., 2008, vol. 453, pp. 147-156.

75. J. Zhao, T. Wang, J. Chen, L. Fu, J. He: Materials, 2017, vol. 10, pp. 1-10.

76. E.G. Kandalova, V.I. Nikitin, J. Wanqi, A.G. Makarenko: Matt. Lett., 2002, vol. 54, pp. 131-134.

77. Z. Liu, M. Rakita, X. Wang, W. Xu, Q. Han: J. Mater. Res., 2014, vol. 29, pp. 1354-1361.

X. Wang, A. Jha, R. Brydson: Mater. Sci. Eng. A, 2004, vol. 364, pp. 339-345.

79. R. Nikbakht, H. Assadi: Acta Mater., 2012, vol. 60, pp. 4041-4053.

80. B.B. Khina, B. Formanek, I. Solpan: Physica B-Condensed Matter, 2005, vol. 355, pp. 14-31.

81. M. Ge, D.S. Coburn, E. Nazaretski, W. Xu, K. Gofron, H. Xu, Z. Yin, W.-K. Lee: Appl. Phys. Lett., 2018, vol. 113, pp. 083109

Acknowledgments

This research used resources of the Advanced Photon Source, a U.S. Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357. The authors gratefully acknowledge financial support from the Melt R2-2 project funded by LIFT (Lightweight Innovations For Tomorrow), a Manufacturing Institute under the contract from the Office of Naval Research (Contract # N00014-14-2-002), as well as financial support from the National Science Foundation (Award # 1762657). The authors also acknowledge financial support from the University of Michigan College of Engineering and technical support from the Michigan Center for Materials Characterization. We also thank David Weiss at Eck Industries and Stephen Udvardy at the North American Die Casting Association for helpful discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 14, 2019.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Electronic supplementary material 2 (AVI 3162 kb)

Rights and permissions

About this article

Cite this article

Reese, C.W., Gladstein, A., Fedors, J.M. et al. In Situ Al-TiC Composites Fabricated by Self-propagating High-Temperature Reaction: Insights on Reaction Pathways and Their Microstructural Signatures. Metall Mater Trans A 51, 3587–3600 (2020). https://doi.org/10.1007/s11661-020-05786-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05786-1