Abstract

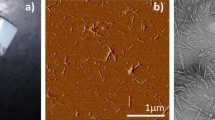

The use of nanocelluloses is being conducted for the most diverse applications. Their performance as coating agent has been mainly explored to improve barrier properties, as they emerge as perfect candidate for plastic substitution, but it is also important to explore their potential to improve printing quality. In the present work, the influence of different nanocelluloses, obtained through mechanical, enzymatic, TEMPO-mediated oxidation and carboxymethylation treatments, in the coating process and inkjet printability of office papers was assessed. The results revealed that the cellulose nanofibrils are better for printability than the microfibrils. But the size and charge of the former must be taken into account, since fibrils of very small size penetrate the paper structure, dragging the pigments from the surface, and very anionic nanofibrils can also have negative influence on the optical density. Besides, an interesting synergy between surface-sizing starch and the cellulose nanofibrils was found to occur as the latter closed the paper structure, which prevented starch from penetrating, while potentiating both of their positive effects on ink pigment entrapment. An additional study of characterization of inkjet pigments was also performed.

Similar content being viewed by others

References

Ankerfors M (2012) Microfibrillated cellulose: energy-efficient preparation techniques and key properties. Litentiate thesis presented to Innventia AB and KTH Royal Institute of Technology

Aspler J, Bouchard J, Hamad W, Berry R, Beck S, Drolet F, Zou X (2013) Review of nanocellulosic products and their applications. In: Dufresne A, Thomas S, Pothan LA (eds) Biopolymer nanocomposites: processing, properties, and applications, 1st edn. Wiley, Hoboken, NJ

Aulin C, Gällstedt M, Lindström T (2010) Oxygen and oil barrier properties of microfibrillated cellulose films and coatings. Cellulose 17:559–574

Bacakova L, Pajorova J, Bacakova M, Skogberg A, Kallio P, Kolarova K, Svorcik V (2019) Versatile application of nanocellulose: from industry to skin tissue engineering and wound healing. Nanomaterials 9:164

Chen YW, Lee HV, Hamid SBA (2017) Investigation of optimal conditions for production of highly crystalline nanocellulose with increased yield via novel Cr(III)-catalyzed hydrolysis: response surface methodology. Carbohydr Polym 178:57–68

Dimic-Misic K, Puisto A, Paltakari J, Alava M, Maloney T (2013) The influence of shear on the dewatering of high consistency nanofibrillated cellulose furnishes. Cellulose 20:1853–1864

Dimic-Misic K, Vanhatalo K, Dahl O, Gane P (2018) Rheological properties comparison of aqueous dispersed nanocellulose derived from a novel pathway-produced microcrystalline cellulose or by conventional methods. Appl Rheol 28:64474

Eriksen Ø, Gregersen ØW (2005) The influence of ink pigment penetration and paper structure on print through. Nord Pulp Pap Res J 20(2):242–246

Gómez N, Santos SM, Carbajo JM, Villar JC (2017) Use of bacterial cellulose in degraded paper restoration: effect on visual appearance of printed paper. BioResources 12(4):9130–9142

Hamada H, Mitsuhashi M (2016) Effect of cellulose nanofibers as a coating agent for woven and nonwoven fabrics. Nord Pulp Pap Res J 31(2):255–260

Hamada H, Beckvermit J, Bousfield DW (2010) Nanofibrillated cellulose with fine clay as a coating agent to improve print quality. In: Paper conference and trade show 2010 (PaperCon 2010) TAPPI Press, Atlanta, Georgia, USA, pp 854–880

Henriksson M, Berglund LA, Isaksson P, Lindstrom T, Nishino T (2008) Cellulose nanopaper structures of high toughness. Biomacromolecules 9:1579–1585

Hubbe MA, Beck KR, O’Neal WG, Sharma YC (2012) Cellulosic substrates for removal of pollutants from aqueous systems: a review. 2. Dyes. Bioresources 7(2):2582–2687

Hubbe MA, Ferrer A, Tyagi P, Yin Y, Salas C, Pal L, Rojas OJ (2017a) Nanocellulose in thin films, coatings, and plies for packaging applications: a review. BioResources 12(1):2143–2233

Hubbe MA, Tayeb P, Joyce M, Tyagi P, Kehoe M, Dimic-Misic Pal L (2017b) Rheology of nanocellulose-rich aqueous suspensions: a review. BioResources 12(4):9556–9661

Imani M, Ghasemian A, Dehghani-Firouzabadi MR, Afra E, Gane PAC, Rojas OJ (2019) Nano-lignocellulose from recycled fibres in coatings from aqueous and ethanolic media: effect of residual lignin on wetting and offset printing quality. Nord Pulp Pap Res J 34(2):200–210

Kumar V, Koppolu VR, Bousfield D, Toivakka M (2017) Substrate role in coating of microfibrillated cellulose suspensions. Cellulose 24:1247–1260

Lavoine N, Desloges I, Khelifi B, Bras J (2014) Impact of different coating processes of microfibrillated cellulose on the mechanical and barrier properties of paper. J Mater Sci 49:2879–2893

Lee HL, Shin JY, Koh C-H, Ryu H, Lee D-J, Sohn C (2002) Surface sizing with cationic starch: its effect on paper quality and papermaking process. Tappi J 1(1):34–40

Li H, Qi Y, Zhao Y, Chi J, Cheng S (2019) Starch and its derivatives for paper coatings: a review. Prog Org Coat 135:213–227

Lin N, Dufresne A (2014) Nanocellulose in biomedicine: current status and future prospect. Eur Polym J 59:302–325

Lourenço AF, Gamelas JAF, Nunes T, Amaral J, Mutjé P, Ferreira PJ (2017) Influence of TEMPO-oxidised cellulose nanofibrils on the properties of filler-containing papers. Cellulose 24:349–362

Lourenço AF, Godinho D, Gamelas JAF, Sarmento P, Ferreira PJT (2019a) Carboxymethylated cellulose nanofibrils in papermaking: influence on filler retention and paper properties. Cellulose 26:3489–3502

Lourenço AF, Gamelas JAF, Sarmento P, Ferreira PJT (2019b) Enzymatic nanocellulose in papermaking—the key role as filler flocculant and strengthening agent. Carbohydr Polym 224:115200

Luu W, Bousfield D, Kettle J (2011) Application of nano-fibrillated cellulose as a paper surface treatment for inkjet printing. In: Paper conference and trade show 2010 (PaperCon 2010) TAPPI Press, Atlanta, Georgia, USA, pp 2222–2233

Miller J (2019) Nanocellulose: packaging applications and markets. RISI

Moutinho IMT, Ferreira PJT, Figueiredo ML (2007) Impact of surface sizing on inkjet printing quality. Ind Eng Chem Res 46:6183–6188

Nazari B, Bousfield DW (2016) Cellulose nanofibers influence on properties and processing of paperboard coating. Nord Pulp Pap Res J 31(3):511–520

Nechyporchuk O, Belgacem MN, Pignon F (2016) Current progress in rheology of cellulose nanofibril suspensions. Biomacromolecules 17:2311–2320

Nemoto J, Saito T, Isogai A (2015) Simple freeze-drying procedure for producing nanocellulose aerogel-containing, high-performance air filters. ACS Appl Mater Interfaces 7(35):19809–19815

Nygårds S (2011) Nanocellulose in pigment coatings—aspects of barrier properties and printability in offset. Dissertation presented to Linköping University, Sweden

Placket DV, Letchford K, Jackson JK, Burt HM (2014) A review of nanocellulose as a novel vehicle for drug delivery. Nord Pulp Pap Res J 29(1):105–118

Rautkoski H, Pajari H, Koskela H, Sneck A, Moilanen P (2015) Use of cellulose nanofibrils (CNF) in coating colors. Nord Pulp Pap Res J 30(3):511–518

Ridgway CJ, Gane PAC (2012) Constructing NFC-pigment composite surface treatment for enhanced paper stiffness and surface properties. Cellulose 19:547–560

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulosenanofibres prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8:2485–2491

Saraiva MS, Gamelas JAF, de Sousa APM, Reis BM, Amaral JL, Ferreira PJ (2010) A new approach for the modification of paper surface properties using polyoxometalates. Materials 3(1):201–215

Song H, Ankerfors M, Hoc M, Lindström T (2010) Reduction of the linting and dusting propensity of newspaper using starch and microfibrillated cellulose. Nord Pulp Pap Res J 25(4):495–504

Sousa S, Gamelas JA, Mendes AO, Fiadeiro PT, Ramos A (2013) Interactions of ink colourants with chemically modified paper surfaces concerning inkjet print improvement. Mater Chem Phys 139:877–884

Sousa S, Sousa AM, Reis B, Ramos A (2014) Influence of binders on inkjet print quality materials. Science Medziagotyra 20(1):1392

Syverud K, Stenius P (2009) Strength and barrier properties of MFC films. Cellulose 16:75–85

Tarrés Q, Delgado-Aguilar M, Pèlach MA, González I, Boufi S, Mutjé P (2016) Remarkable increase of paper strength by combining enzymatic cellulose nanofibers in bulk and TEMPO-oxidized nanofibers as coating. Cellulose 23:3939–3950

Torvinen K, Sievänen J, Hjelt T, Hellén E (2012) Smooth and flexible filler-nanocellulose composite structure for printed electronics applications. Cellulose 19:821–829

Wagberg L, Decher G, Norgren M, Lindström T, Ankerfors M, Axnäs K (2008) The build-up of polyelectrolyte multilayers of microfibrillated cellulose and cationic polyelectrolytes. Langmuir 24:784–795

Yuen CWM, Ku SKA, Choi PSR, Kan CW, Tsang SY (2005) Determining functional groups of commercially available ink-jet printing reactive dyes using infrared spectroscopy. Res J Text Appar 9(2):26–38

Zhang H, Dou C, Pal L, Hubbe MA (2019) Review of electrically conductive composites and films containing cellulosic fibers or nanocellulose. BioResources 14(3):7494–7542

Acknowledgments

This work was supported by Fundacão para a Ciência e a Tecnologia (FCT), Portugal [SFRH/BDE/108095/2015]. Some of the work was conducted under Project inpactus—innovative products and technologies from eucalyptus, Project No. 21874 funded by Portugal 2020 through European Regional Development Fund (ERDF) in the frame of COMPETE 2020 no 246/AXIS II/2017.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lourenço, A.F., Gamelas, J.A.F., Sarmento, P. et al. Cellulose micro and nanofibrils as coating agent for improved printability in office papers. Cellulose 27, 6001–6010 (2020). https://doi.org/10.1007/s10570-020-03184-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03184-9