Abstract

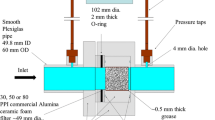

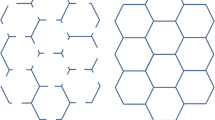

There has been reluctance from many iron foundries to adopt naturally pressurized gating systems due to the lack of knowledge on the application of the theories set out by Dr. John Campbell. The applications of naturally pressurized gating systems are still evolving and, in many cases, are counterintuitive to foundry engineers. This research tested proposed gating system behavior during filling, and from the resulting data, velocity losses (friction coefficients) through ceramic foam filters were measured. The verification of the velocity by modeling and simulation of these systems proved relatively accurate in most cases studied. The research concluded that a vertical vortex sprue system had the highest velocity reduction, reducing it by 37% (friction coefficient of 0.63), but had some initial air bubbles travel through the gate before steady-state flow occurred. The most effective gating system tested was a bottom gate and ceramic foam filter combination utilizing a bypass for the initial damaged metal and initial velocity reduction. The in-line gating using 10PPI and 20 PPI ceramic foam filters had a reduction in velocity of 16% and 28%, respectively, but caused major bubbles and jetting of the initial metal at the gate. When using filters in-line with the runner, the filter print and the bypass should be vented and the bypass have sufficient volume to counteract the initial high-velocity metal entering from the sprue. A bypass of sufficient size, reduced the initial velocity of metal through the gate, allowed priming of the filter, eliminated jetting, and reduced the chance of damaged metal from entering the mold.

Similar content being viewed by others

References

J. Campbell, Complete Casting Handbook, 2nd edn. (Butterworth-Heinemann, Oxford, 2015). ISBN 978-0-444-63509-9

S. Liu, C.R. Loper Jr., Morphology of Kish Graphite. Trans. Am. Foundrym. Soc. 98, 385–394 (1990)

C.R. Loper Jr., A.J. Salg, Exfoliated Dross Formation in Heavy Section Ductile Iron Castings. Trans. Am. Foundrym. Soc. 84, 765–768 (1976)

J.W. Wildermuth, R.H. Lutz, C.R. Loper Jr., A Study of Thin Metal Ingate Restrictions in Steel and Ductile Iron Castings. Trans. Am. Foundrym. Soc. 76, 258–263 (1968)

J. Furness, Conversation Regarding the Measurement of Velocity and Jetting of Molten Metal (University of Wisconsin, Platteville, 2010)

R. Puhakka, Telephone Conversations Regarding the Initial Filling of the Basin and Stopper Rod Use and Design. Durban South Africa, 15 September 2018

R.W. Heine, C.R. Loper Jr., P.C. Rosenthal, Principles of Metalcasting (McGraw-Hill Book Company, New York, 1967). ISBN 10:0070278962

S.H. Majidi, C. Beckermann, Effect of pouring conditions and gating system design on air entrainment during mold filling. Int. J. Metalcast. 13, 255–272 (2019). https://doi.org/10.1007/s40962-018-0272-x5-272

J.F. Wallace, E.B. Evans, Gating OG gray iron castings. Trans. Am. Foundrym. Soc. 65, 267–275 (1957)

Course Notes For Gating and Risering Course—Iron. American Foundry Society. University of Wisconsin-Platteville: Cast Metals Institute, 2005. Vols. CMI Course No. 7-235L—Gating & Riser Design - Ferrous (47-05)

L.S. Aubrey, J.W. Brockmeyer, P.F. Wieser, Dross removal from ductile iron with ceramic foam filters. Trans. Am. Foundrym. Soc. 93, 171–176 (1985)

J.R. Schmahl, L.S. Aubrey, Filtration with reticulated silicon carbide foam—an effective means for inclusion removal in gray and nodular iron castings. Trans. Am. Foundrym. Soc. 101, 1011–1020 (1993)

A.C. Midea, Pressure drop characterisitcs of iron filters. Trans. Am. Foundrym. Soc. 109, 51–59 (2001)

P.R. Kahn et al., Flow of ductile iron through ceramic filters and the effects on the dross and fatigue properties. Trans. Am. Foundrym. Soc. 95, 105–116 (1987)

Acknowledgements

The authors would like to thank: The University of Wisconsin-Platteville for sabbatical support to do this research., MAGMA, University of Johannesburg and the Metal Casting Technology Station, FOSECO, SELEE, and Pinetown Engineering and Foundry Co (PEFCO), as well as Frank Headington, Tom Prucha, Jim Furness, Bob Puhakka, and John Campbell.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Metzloff, K., Mageza, K. & Sekotlong, D. Velocity Measurement and Verification with Modeling of Naturally Pressurized Gating Systems. Inter Metalcast 14, 610–621 (2020). https://doi.org/10.1007/s40962-020-00471-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00471-w