Abstract

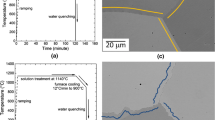

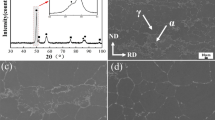

A post-creep deformation analysis is carried out on the nickel-based superalloy Inconel 617 in order to identify the grain boundary carbide (GBC) distributions for different creep stresses and temperatures and to determine the related microstructural changes in terms of grain size and associated changes in the material’s creep ductility as a function of GBC distribution. Creep tests were conducted at two temperatures 900 °C and 950 °C for stresses of 35, 50, and 62 MPa. Post-creep rupture, carbide size, density, and spacing were measured as a function of grain boundary orientation with respect to the loading direction (i.e., trace angle). It is observed that non-uniform carbide distributions were present in the five test conditions associated with an increase in the carbide size, density, and area fraction along grain boundaries perpendicular to loading conditions (tensile boundaries) when compared to those on parallel boundaries (compressive boundaries). The magnitude of preferential distribution of GBC towards tensile boundaries is observed to govern the ability of the compressive boundaries to migrate which facilitates grain elongation in the loading direction which leads to increased creep ductility. A critical magnitude of preferential GBC distribution is determined below which compressive boundaries remain relatively pinned with a low grain boundary spacing. This condition corresponds to creep deformation accommodated by grain boundary sliding only, leading to a relatively low creep rupture strain. Above that magnitude, compressive boundaries are permitted to slide and migrate and, as such, facilitate grain elongation giving rise to increasing magnitude of total creep strain. A criterion for significant preferential distribution resulting in changes to grain morphology and mechanical response, has been proposed in the form of a temperature-stress map which identifies the creep loading conditions associated with significant preferential distribution prior to creep rupture. The critical GBC distribution coupled with the concept of identifying temperature and stress combinations resulting in significant preferential distribution provides guidelines for creep testing for the purpose of extrapolating short-term test data to long-term response.

Similar content being viewed by others

References

Mankins, W. L., J. C. Hosier, and T. H. Bassford: Metall. Trans., 1974, 5(12), pp.2579-2590

Y. Guo, B. Wang, and S. Hou: Acta Metall. Sin., 2013, 26(3), pp. 307-312

Li, X., Le Pierres, R., & Dewson, S. J: In Proceedings of ICAPP, 2006, 6, pp. 4-8

Kihara, Shigemitsu, John B. Newkirk, Akira Ohtomo, and Yoshinori Saiga: Metall. Trans. A, 1980, 11(6), pp.1019-1031

Sabol, G. P., and R. Stickler: Phys. Status Solidi B, 1969, 35(1), pp.11-52.

Furillo, F. T., J. M. Davidson, J. K. Tien, and L. A. Jackman: Mater. Sci. Eng., 1979, 39(2), pp.267-273

Wu, X. J., and A. K. Koul: Metall. Mater. Trans. A, 1995, 26(4), pp.905-914

Raj, R., and M. F. Ashby: Metall. Mater. Trans. B, 1972, 3(7), pp.1937-1942

Cook, R.H.: Nucl. Technol., 1984, 66(2), pp.283-288

Wright, R. N.: Idaho National Laboratory, 2006, No. INL/EXT-06-11750

Schlegel S, Hopkins S, Young E, Cole J, Lillo T, and Frary M: Metall. Mater. Trans. A, 2009, 40(12), pp. 2812-2823

Howell, P. R., J. O. Nilsson, and G. L. Dunlop: J. Mater. Sci., 1978, 13(9), pp.2022-2028

Kang, J-H., and P. E. J. Rivera: Comput. Mater. Sci., 2013, 67, pp. 364-372

Zhang, S. Z., M. M. Li, and R. Yang: Mater. Charact., 2011, 62(12), pp.1151-1157

Rahman, S., G. Priyadarshan, K. S. Raja, C. Nesbitt, and M. Misra: Mech. Mater., 2009, 41(3), pp. 261-270

Special Metals: 2005, Publication Number SMC-029

Benz, J. K., L.J. Carroll, J. K. Wright, R.N. Wright, and T. M. Lillo: Metall. Mater. Trans. A, 2014, 45(7), pp. 3010-3022

Osthoff, Walter, Hans Schuster, Philip J. Ennis, and Hubertus Nickel: Nucl. Technol., 1984, 66(2), pp.296-307

Kim, W-G, J-Y Park, I.M.W. Ekaputra, M-H. Kim, and Y.-W. Kim (2014) Procedia Mater. Sci. 3, pp. 1285-1290

Chomette S, JM Gentzbittel, B Viguier (2010) J. Nucl. Mater. 399, pp. 266-274

Lillo, T. M., and R. N. Wright: ASME Pressure Vessels Piping Conf., 2015, American Society of Mechanical Engineers

Rettberg, L. H., and T. M. Pollock: Acta Mater., 2014, 73, pp.287-297

Koul AK, JPA Immarigeon: Metall. Trans. A, 1985, 16(1), pp. 51-57

Iwashita, C. H., and R. P. Wei: Acta Mater., 2000, 48(12), pp.3145-3156

He, L. Z., Q. Zheng, X. F. Sun, G. C. Hou, H. R. Guan, and Z. Q. Hu: J. Mater. Sci., 2005, 40(11), pp.2959-2964

ASTM Standard E112-12, 2012, https://doi.org/10.1520/e0112-12

Srolovitz, D. J., M. P. Anderson, G. S. Grest, and P. S. Sahni: Acta Metall., 1984, 32(9), pp.1429-1438

Song X, G Liu, N Gu (1999) Mater. Sci. Eng. A 270(2), pp. 178-182

Chang, Kunok, Weiming Feng, and Long-Qing Chen: Acta Mater., 2009, 57(17), pp.5229-5236

Wang, G., D. S. Xu, E. J. Payton, N. Ma, R. Yang, M. J. Mills, and Y. Wang: Acta Mater., 2011, 59(11), pp. 4587-4594

Markuszewicz, M., J. Groyecki, J. Lassota, and A. Zawada: AIME MET SOC TRANS, 1966, 236(2), pp. 196-200

Wang, Dong, Chang Liu, Jian Zhang, and Langhong Lou: Matrix, 2012, 6, pp. 23

Gavriljuk VG (2003) Mater. Sci. Eng. A 345, pp. 81-89

Lapera M, D Spader, and H Ghonem (2020) Mater. Sci. Eng. A, 769:138421

Spader D, M Lapera, H Ghonem (2020) Mater. Sci. Eng. A 769, 138355

Pleune, T. T.: PhD diss., 1999

Acknowledgments

The authors would like to acknowledge the Rhode Island Space Grant for their support (Fellowship to Daniel Spader) during the course of this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted September 2, 2019.

Rights and permissions

About this article

Cite this article

Spader, D., Maciejewski, K. & Ghonem, H. Distribution of Grain Boundary Carbides in Inconel 617 Subjected to Creep at 900 °C and 950 °C. Metall Mater Trans A 51, 3473–3487 (2020). https://doi.org/10.1007/s11661-020-05798-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05798-x