Abstract

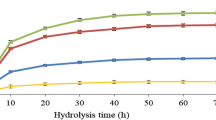

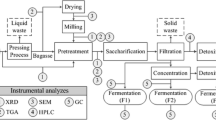

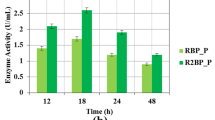

For every 1 tonne of bananas produced, 3 tonnes of pseudostem waste is also created. The aim of this research is to improve the pre-treatment methods used in converting this renewable resource to bioethanol. The microwave-assisted liquid hot water and alkaline with sodium hydroxide were performed on banana pseudostem followed by saccharification and fermentation to ethanol. The liquid hot water pre-treatment was performed over a range of severities (1.88–4.84). The alkaline pre-treatment was carried out to evaluate the effect of NaOH loading (0.09–0.3 g NaOH g−1 dry banana pseudostem) and severity factor (3.65–4.84). The severity factor of 4.84 from the liquid hot water pre-treatment and run 1 (Log Ro 3.65, 0.09 g NaOH g−1 dry banana pseudostem) from the alkaline pre-treatment reached the highest enzymatic hydrolysis yields for each pre-treatment conditions and were chosen to be submitted to fermentation. Subsequently, simultaneous saccharification and fermentation (SSF) at 25 °C for 120 h, using samples from alkaline (Log Ro 3.65, 0.09 g NaOH g−1 dry banana pseudostem) and liquid hot water (Log Ro 4.84) pre-treatments, resulted in 92 wt% and 95 wt% of the theoretical ethanol yield respectively, comparing to 60 wt% from the untreated biomass. The liquid hot water is considered a more suitable pre-treatment, as it is more economical and is an environmentally friendly alternative compared to the alkaline pre-treatment. The latter can lead to pollution as the sodium discharge in the process effluent is difficult to recycle and so may limit its application on a commercial scale.

Similar content being viewed by others

References

Block G (2015) Interlaw book on renewables energies. Bruylant, Bruxelles

FAOSTAT (2017) Food and Agriculture Organization of the United Nations (FAO). FAOSTAT, In http://www.fao.org/faostat/en/?#data/QC

Souza EL, Liebl GF, Marangoni C et al (2014) Bioethanol from fresh and dried banana plant pseudostem. Chem Eng Trans 38:271–276. https://doi.org/10.3303/CET1438046

Brodeur G, Yau E, Badal K et al (2011) Chemical and physicochemical pretreatment of lignocellulosic biomass: a review. Enzyme Res 2011:1–17. https://doi.org/10.4061/2011/787532

Yu Q, Zhuang X, Yuan Z et al (2010) Two-step liquid hot water pretreatment of Eucalyptus grandis to enhance sugar recovery and enzymatic digestibility of cellulose. Bioresour Technol 101:4895–4899. https://doi.org/10.1016/j.biortech.2009.11.051

Maurya DP, Singla A, Negi S (2015) An overview of key pretreatment processes for biological conversion of lignocellulosic biomass to bioethanol. 3 Biotech 5:597–609. https://doi.org/10.1007/s13205-015-0279-4

Kumari D, Singh R (2018) Pretreatment of lignocellulosic wastes for biofuel production: a critical review. Renew Sust Energ Rev 90:877–891. https://doi.org/10.1016/j.rser.2018.03.111

Oushabi A, Sair S, Oudrhiri Hassani F et al (2017) The effect of alkali treatment on mechanical, morphological and thermal properties of date palm fibers (DPFs): study of the interface of DPF–polyurethane composite. South African J Chem Eng 23:116–123. https://doi.org/10.1016/j.sajce.2017.04.005

Kumar R, Wyman CE (2009) Effects of cellulase and xylanase enzymes on the deconstruction of solids from pretreatment of poplar by leading technologies. Am Inst Chem Eng 25. https://doi.org/10.1021/bp.102

Mensah ECB and MY, Mensah ECB and MY (2018) Fuel ethanol production from sugarcane. In: Long-haul travel motivation by international tourist to Penang. p 13

Gabhane J, Prince William SPM, Vaidya AN et al (2011) Influence of heating source on the efficacy of lignocellulosic pretreatment - a cellulosic ethanol perspective. Biomass Bioenergy 35:96–102. https://doi.org/10.1016/j.biombioe.2010.08.026

Galia A, Schiavo B, Antonetti C, Galletti AMR, Interrante L, Lessi M, Scialdone O, Valenti MG (2015) Autohydrolysis pretreatment of Arundo donax: a comparison between microwave-assisted batch and fast heating rate flow-through reaction systems. Biotechnol Biofuels 8:1–18. https://doi.org/10.1186/s13068-015-0398-5

Amini N, Haritos VS, Tanksale A (2018) Microwave assisted pretreatment of eucalyptus sawdust enhances enzymatic saccharification and maximizes fermentable sugar yield. Renew Energy 127:653–660. https://doi.org/10.1016/j.renene.2018.05.001

Wei W, Zhang H, Jin Y (2019) Comparison of microwave-assisted zinc chloride hydrate and alkali pretreatments for enhancing eucalyptus enzymatic saccharification. Energy Convers Manag 186:42–50. https://doi.org/10.1016/j.enconman.2019.02.054

Overend RP, Chornet E, Gascoigne JA (1987) Fractionation of lignocellulosics by steam-aqueous pretreatments [and discussion]. Philos Trans R Soc A Math Phys Eng Sci 321:523–536. https://doi.org/10.1098/rsta.1987.0029

Ghose (1987) Measurement of cellulase activities. Pure Appl Chem 59:257–268. https://doi.org/10.1351/pac198759020257

Blakeney AB, Harris PJ, Henry RJ, Stone BA (1983) A simple and rapid preparation of alditol acetates for monosaccharide analysis. Carbohydr Res 113:291–299. https://doi.org/10.1016/0008-6215(83)88244-5

Saeman JF, Bubl JL, Harris EE (1945) Quantitative saccharification of wood and cellulose. Ind Eng Chem Anal Ed 17:35–37. https://doi.org/10.1021/i560137a008

Guerrero AB, Ballesteros I, Ballesteros M (2017) Optimal conditions of acid-catalysed steam explosion pretreatment of banana lignocellulosic biomass for fermentable sugar production. J Chem Technol Biotechnol 92:2351–2359. https://doi.org/10.1002/jctb.5239

Santa-Maria M, Ruiz-Colorado AA, Cruz G, Jeoh T (2013) Assessing the feasibility of biofuel production from lignocellulosic banana waste in rural agricultural communities in Peru and Colombia. Bioenergy Res 6:1000–1011. https://doi.org/10.1007/s12155-013-9333-4

Djajadi DT, Hansen AR, Jensen A, Thygesen LG, Pinelo M, Meyer AS, Jørgensen H (2017) Surface properties correlate to the digestibility of hydrothermally pretreated lignocellulosic Poaceae biomass feedstocks. Biotechnol Biofuels 10:1–15. https://doi.org/10.1186/s13068-017-0730-3

Low JC, Halis R, Shah UKM et al (2015) Enhancing enzymatic digestibility of alkaline pretreated banana pseudostem for sugar production. BioResources 10:1213–1223. https://doi.org/10.15376/biores.10.1.1213-1223

Kim JS, Lee YY, Kim TH (2016) A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour Technol 199:42–48. https://doi.org/10.1016/j.biortech.2015.08.085

Chen,Y.;Stevens,M.A.;Zhu,Y.;Holmes,J.;Xu H (2013) Understanding of alkaline preteatment parameters for corn stover enzymatic saccharification. Biotechnol Biofuels 1–10

Rasmussen H, Sørensen HR, Meyer AS (2014) Formation of degradation compounds from lignocellulosic biomass in the biorefinery: sugar reaction mechanisms. Carbohydr Res 385:45–57. https://doi.org/10.1016/j.carres.2013.08.029

Ho LH, Tan TC, Aziz NA, Bhat R (2015) In vitro starch digestibility of bread with banana (Musa acuminata X balbisiana ABB cv. Awak) pseudo-stem flour and hydrocolloids. Food Biosci 12:10–17. https://doi.org/10.1016/j.fbio.2015.07.003

Gholap B, Kannor D, Gagare S, Mahajan J (2011) Starch extraction from banana pseudostem. Int J Process Post Harvest Technol 2:12–16

Souto LRF, da Silva IF, Ninow JL et al (2019) Effect of hydrothermal pre-treatment on duckweed (Landoltia punctata) biomass for simultaneous saccharification and fermentation process. Biomass Bioenergy 127:105259. https://doi.org/10.1016/j.biombioe.2019.105259

Guerrero AB, Ballesteros I, Ballesteros M (2018) The potential of agricultural banana waste for bioethanol production. Fuel 213:176–185. https://doi.org/10.1016/j.fuel.2017.10.105

Merali Z, Collins SRA, Elliston A, Wilson DR, Käsper A, Waldron KW (2015) Characterization of cell wall components of wheat bran following hydrothermal pretreatment and fractionation. Biotechnol Biofuels 8:1–13. https://doi.org/10.1186/s13068-015-0207-1

Jönsson LJ, Martín C (2016) Pretreatment of lignocellulose: formation of inhibitory by-products and strategies for minimizing their effects. Bioresour Technol 199:103–112. https://doi.org/10.1016/j.biortech.2015.10.009

Caspeta L, Castillo T, Nielsen J (2015) Modifying yeast tolerance to inhibitory conditions of ethanol production processes. Front Bioeng Biotechnol 3:1–15. https://doi.org/10.3389/fbioe.2015.00184

Wu J, Elliston A, Le Gall G et al (2018) Optimising conditions for bioethanol production from rice husk and rice straw: effects of pre-treatment on liquor composition and fermentation inhibitors. Biotechnol Biofuels 11:1–13. https://doi.org/10.1186/s13068-018-1062-7

Fosso-Kankeu E, Marx S, Meyer A (2015) Simulated inhibitory effects of typical byproducts of biomass pretreatment process on the viability of Saccharomyces cerevisiae and bioethanol production yield. Afr J Biotechnol 14:2383–2394. https://doi.org/10.4314/ajb.v14i30

Gonçalves Filho LC, Fisher GAA, Sellin N, Souza O (2013) Hydrolysis of banana tree pseudostem and second-generation ethanol production by Saccharomyces cerevisae. J Environ Sci Eng 2:65–69

Martín C, Wei M, Xiong S, Jönsson LJ (2017) Enhancing saccharification of cassava stems by starch hydrolysis prior to pretreatment. Ind Crop Prod 97:21–31. https://doi.org/10.1016/j.indcrop.2016.11.067

Khullar E, Dien BS, Rausch KD et al (2013) Effect of particle size on enzymatic hydrolysis of pretreated Miscanthus. Ind Crop Prod 44:11–17. https://doi.org/10.1016/j.indcrop.2012.10.015

Grimaldi MP, Marques MP, Laluce C, Cilli EM, Sponchiado SRP (2015) Evaluation of lime and hydrothermal pretreatments for efficient enzymatic hydrolysis of raw sugarcane bagasse. Biotechnol Biofuels 8:1–14. https://doi.org/10.1186/s13068-015-0384-y

Li F, Yang L, Lv X, Liu D, Xia H, Chen S (2016) Purification and characterization of a novel extracellular alkaline protease from Cellulomonas bogoriensis. Protein Expr Purif 121:125–132. https://doi.org/10.1016/j.pep.2016.01.019

Oliva M, Manzanares P, Ballesteros I et al (2017) A sequential steam explosion and reactive extrusion pretreatment for lignocellulosic biomass conversion within a fermentation-based biorefinery perspective. Fermentation 3:15. https://doi.org/10.3390/fermentation3020015

Yeh AI, Huang YC, Chen SH (2010) Effect of particle size on the rate of enzymatic hydrolysis of cellulose. Carbohydr Polym 79:192–199. https://doi.org/10.1016/j.carbpol.2009.07.049

Zhang J, Tang M, Viikari L (2012) Xylans inhibit enzymatic hydrolysis of lignocellulosic materials by cellulases. Bioresour Technol 121:8–12. https://doi.org/10.1016/j.biortech.2012.07.010

Wilkinson S, Smart KA, James S, Cook DJ (2016) Maximising high solid loading enzymatic saccharification yield from acid-catalysed hydrothermally-pretreated brewers spent grain. Biofuel Res J 3:417–429. https://doi.org/10.18331/BRJ2016.3.2.7

Gupta R, Lee YY (2010) Investigation of biomass degradation mechanism in pretreatment of switchgrass by aqueous ammonia and sodium hydroxide. Bioresour Technol 101:8185–8191. https://doi.org/10.1016/j.biortech.2010.05.039

Andreaus J, Azevedo H, Cavaco-Paulo A (1999) Effects of temperature on the cellulose binding ability of cellulase enzymes. J Mol Catal B Enzym 7:233–239. https://doi.org/10.1016/S1381-1177(99)00032-6

Fu X, Yan Q, Wang J, Yang S, Jiang Z (2016) Purification and biochemical characterization of novel acidic chitinase from Paenicibacillus barengoltzii. Int J Biol Macromol 91:973–979. https://doi.org/10.1016/j.ijbiomac.2016.06.050

Wojtusik M, Zurita M, Villar JC, Ladero M, Garcia-Ochoa F (2016) Influence of fluid dynamic conditions on enzymatic hydrolysis of lignocellulosic biomass: effect of mass transfer rate. Bioresour Technol 216:28–35. https://doi.org/10.1016/j.biortech.2016.05.042

Triwahyuni E, Muryanto SY, Abimanyu H (2015) The effect of substrate loading on simultaneous saccharification and fermentation process for bioethanol production from oil palm empty fruit bunches. Energy Procedia 68:138–146. https://doi.org/10.1016/j.egypro.2015.03.242

Zhao X, Moates GK, Elliston A, Wilson DR, Coleman MJ, Waldron KW (2015) Simultaneous saccharification and fermentation of steam exploded duckweed: improvement of the ethanol yield by increasing yeast titre. Bioresour Technol 194:263–269. https://doi.org/10.1016/j.biortech.2015.06.131

Ingale S, Joshi SJ, Gupte A (2014) Production of bioethanol using agricultural waste: banana pseudo stem. Braz J Microbiol 45:885–892. https://doi.org/10.1590/S1517-83822014000300018

Funding

This work was supported by the BBSRC Institute Strategic Programme “Food and Health” Grant No. BB/J004545/1. CNPq (National Council for Scientific and Technological Development—Brazil) also provided financial support in the form of a PhD grant during this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 15 kb)

Rights and permissions

About this article

Cite this article

Ferreira da Silva, I., Reis Fontinelle Souto, L., Collins, S.R.A. et al. Impact of Hot Water and Alkaline Pre-treatments in Cellulosic Ethanol Production from Banana Pseudostem. Bioenerg. Res. 13, 1159–1170 (2020). https://doi.org/10.1007/s12155-020-10123-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-020-10123-w