Abstract

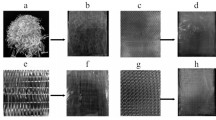

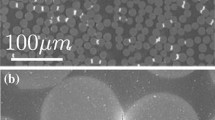

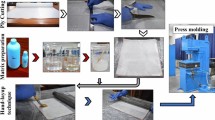

This research focuses on the investigation of endless fiber-reinforced elastomeric materials with special tailoring by different fiber orientations in the composite structure. Therefore, a modified testing device including a suitable specimen production was carried out and the comparability of tests conducted at different test scales (micro- to macro testing level) was proven. Two elastic matrix materials (silicone and polyurethane) and reinforcing fiber types (glass- and polyester fibers) were investigated in all combinations. Due to the important effect on the shear behavior during the deformation of textiles significantly influenced by the fiber orientations of the warp- and weft-yarns, a testing plan was established by using one material combination as a reference setting. Generally, the results reveal a good comparability between different testing levels for the same fiber-matrix combinations and the modified composite testing device has been proven. Furthermore, the significant influence of different fiber orientations on the shear stiffness was investigated.

Similar content being viewed by others

References

Balasooriya, W., Schrittesser, B., Pinter, G., Schwarz, T.: Induced material degradation of elastomers in harsh environments. Polym. Test. 69, 107–115 (2018). https://doi.org/10.1016/j.polymertesting.2018.05.016

Hoffmann, J.: Characterization of fibre reinforced elastomers for shape morphing structural surfaces. Dissertation, Technical University of Munich (2012)

Koschmieder, M.: Verarbeitung und Eigenschaften von Faserverbundkunststoffen mit Elastomermatrix. Dissertation, Rheinisch-Westfälischen Technischen Hochschule Aachen: (2000)

Connolly, F., Walsh, C.J., Bertoldi, K.: Automatic design of fiber-reinforced soft actuators for trajectory matching. Proc. Natl. Acad. Sci. U.S.A. 114, 51–56 (2017). https://doi.org/10.1073/pnas.1615140114

Roche, E.T., Wohlfarth, R., Overvelde, J.T.B., Vasilyev, N.V., et al.: A bioinspired soft actuated material. Adv. Mater. Weinheim 26, 1200–1206 (2014). https://doi.org/10.1002/adma.201304018

Zhang, Q., Wommer, J., O’Rourke, C., Teitelman, J., et al.: Origami and kirigami inspired self-folding for programming three-dimensional shape shifting of polymer sheets with light. Extreme Mech. Lett. 11, 111–120 (2017). https://doi.org/10.1016/j.eml.2016.08.004

Martinez, R.V., Fish, C.R., Chen, X., Whitesides, G.M.: Elastomeric Origami. Programmable Paper-Elastomer Composites as Pneumatic Actuators. Adv. Funct. Mater. 22, 1376–1384 (2012). https://doi.org/10.1002/adfm.201102978

Cianchetti, M., Laschi, C., Menciassi, A., Dario, P.: Biomedical applications of soft robotics. Nat. Rev. Mater. 3, 143–153 (2018). https://doi.org/10.1038/s41578-018-0022-y

Lu, T., Shi, Z., Shi, Q., Wang, T.J.: Bioinspired bicipital muscle with fiber-constrained dielectric elastomer actuator. Extreme Mech. Lett. 6, 75–81 (2016). https://doi.org/10.1016/j.eml.2015.12.008

Zhang, X., Fan, X., Yan, C., Li, H., et al.: Interfacial microstructure and properties of carbon fiber composites modified with graphene oxide. ACS Appl. Mater. Interfaces 4, 1543–1552 (2012). https://doi.org/10.1021/am201757v

Cherif, C.: Textile Werkstoffe für den Leichtbau. Techniken - Verfahren - Materialien - Eigenschaften. Springer-Verlag Berlin Heidelberg, Berlin (2011)

Kalinka, G., Neumann, B.: Bestimmung von Interface-Festigkeit oder Trennarbeit mit dem Pull-out-Versuch (2005)

Zhou, J., Li, Y., Li, N., Hao, X., et al.: Interfacial shear strength of microwave processed carbon fiber/epoxy composites characterized by an improved fiber-bundle pull-out test. Compos. Sci. Technol. 133, 173–183 (2016). https://doi.org/10.1016/j.compscitech.2016.07.033

Piggott, M.R.: Why interface testing by single-fibre methods can be misleading. Compos. Sci. Technol. 57, 965–974 (1997). https://doi.org/10.1016/S0266-3538(97)00036-5

Zhandarov, S.: Characterization of fiber/matrix interface strength. Applicability of different tests, approaches and parameters. Compos. Sci. Technol. 65, 149–160 (2005). https://doi.org/10.1016/j.compscitech.2004.07.003

Kim, J.-K., Mai, Y.-W.: Engineered interfaces in fiber reinforced composites, 1st edn. Elesvier Science Ltd, Oxford (1998)

Palola, S., Sarlin, E., Kolahgar Azari, S., Koutsos, V., et al.: Microwave induced hierarchical nanostructures on aramid fibers and their influence on adhesion properties in a rubber matrix. Appl. Surf. Sci. 410, 145–153 (2017). https://doi.org/10.1016/j.apsusc.2017.03.070

Beter, J., Schrittesser, B., Fuchs, P.: Investigation of adhesion properties in load coupling applications for flexible composites. Mater. Today-Proc. (2020). https://doi.org/10.1016/j.matpr.2020.01.181

Schulz, E., Kalinka, G., Auersch, W.: Effect of transcrystallization in carbon fiber reinforced poly(p -phenylene sulfide) composites on the interfacial shear strength investigated with the single fiber pull-out test. J. Macromol. Sci. Part B. 35, 527–546 (2006). https://doi.org/10.1080/00222349608220393

Desarmot, G., Favre, J.: Advances in pull-out testing and data analysis. Compos. Sci. Technol. 42, 151–187 (1991). https://doi.org/10.1016/0266-3538(91)90016-I

Viel, Q., Esposito, A., Saiter, J.-M., Santulli, C., et al.: Interfacial Characterization by Pull-Out Test of Bamboo Fibers Embedded in Poly(Lactic Acid). Fibers (2018). https://doi.org/10.3390/fib6010007

Kalinka, G., Leistner, A., Hampe, A.: Characterisation of the fibre/matrix interface in reinforced polymers by the push-in technique. Compos. Sci. Technol. 57, 845–851 (1997). https://doi.org/10.1016/S0266-3538(96)00159-5

Domnanovich, A., Peterlik, H., Kromp, K.: Determination of interface parameters for carbon/carbon composites by the fibre-bundle pull-out test. Compos. Sci. Technol. 56, 1017–1029 (1996). https://doi.org/10.1016/0266-3538(96)00060-7

Zarges, J.-C., Kaufhold, C., Feldmann, M., Heim, H.-P.: Single fiber pull-out test of regenerated cellulose fibers in polypropylene. An energetic evaluation. Compos. Part A 105, 19–27 (2018). https://doi.org/10.1016/j.compositesa.2017.10.030

Neitzel, M., Mitschang, P., Breuer, U.: Handbuch Verbundwerkstoffe. Werkstoffe, Verarbeitung, Anwendung. Carl Hanser Fachbuchverlag, Munich (2014)

Berthold, U.: Beitrag zur Thermoformung gewebeverstärkter Thermoplaste mittels elastischer Stempel. Dissertation, Technische Universität Chemnitz: (2001)

Keilig, Th, Arendts, F.J.: Ermittlung und Modellierung des Umformverhaltens von thermoplastischen Gewebeprepregs unter besonderer Berücksichtigung der Atlas-1/7-Bindung. In: Verbundwerkstoffe und Werkstoffverbund. Verbundwerkstoffe und Werkstoffverbund, Kaiserslautern, Germany, September: (1997)

Muliana, A., Rajagopal, K.R., Tscharnuter, D., Schrittesser, B., et al.: Determining material properties of natural rubber using fewer material moduli in virtue ofa novel constitutive approach for elastic bodies. Rubber Chem. Technol. 91, 375–389 (2018). https://doi.org/10.5254/RCT.18.81675

Mansouri, M., Fuchs, P.F., Schuecker, C.: Hyperelastic modeling of woven structures undergoing large deformations. In: 18th European Conference on Composite Materials ECCM18, Athen, 2018 (2018)

Technical Committee ISO/TC 45: Rubber, vulcanized or thermoplastic - Determination of tensile stress-strain properties. International Organization of Standardization, Geneva (2011) CH(ISO 37)

Eurpean Commitee for Standardization: Plastics. Determination of tensile properties. BSI British Standards, London ICS 83.120 (1997)

Hampe, A., Kalinka, G., Meretz, S., Schulz, E.: An advanced equipment for single-fibre pull-out test designed to monitor the fracture process. Compos. 26, 40–46 (1995). https://doi.org/10.1016/0010-4361(94)P3628-E

D13 Committee: Test Method for Tensile Properties of Yarns by the Single-Strand Method. ASTM International, Conshohocken, W., PA(ASTM 2256) (2015)

Abts, G.: Einführung in die Kautschuktechnologie. Hanser, München (2019)

Lang, R.W., Stutz, H., Heym, M., Nissen, D.: Polymere hochleistungs-faserverbundwerkstoffe. Angew. Makromol. Chemie 145, 267–321 (1986). https://doi.org/10.1002/apmc.1986.051450115

Acknowledgements

The author would like to thank Dr. Gerald Kalinka from the Federal Institute for Materials Research and Testing (BAM) in Berlin, Germany, for the support of the experimental work of this project. The research work was performed at the Polymer Competence Center Leoben GmbH (PCCL, Austria) within the framework of the COMET-program of the Federal Ministry for Transport, Innovation and Technology and Federal Ministry for Economy, Family, and Youth, with contributions by the Department of Polymer Engineering and Science (Montanuniversitaet Leoben). The PCCL is funded by the Austrian Government and the State Governments of Styria, Lower Austria, and Upper Austria.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Beter, J., Schrittesser, B., Meier, G. et al. Influence of Fiber Orientation and Adhesion Properties On Tailored Fiber-reinforced Elastomers. Appl Compos Mater 27, 149–164 (2020). https://doi.org/10.1007/s10443-020-09802-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-020-09802-w