Abstract

The fracture mechanics-based IBESS approach is applied to the determination of FAT classes of butt welds with crack initiation along the weld toe. The aim is an investigation of the effect of the geometrical parameters toe radius, flank angle, reinforcement and secondary notches such as roughness or undercuts. The influence of these parameters is discussed both individually and in combination; however, excluding statistical distributions of them and the material data. The results, when compared with conventional FAT classes for butt welds, are encouraging with respect to a potential contribution of IBESS to the discussion of more advanced quality criteria for welds. To that purpose, demands for further research are proposed.

Similar content being viewed by others

1 Introduction

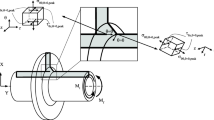

It is well known that the geometry of the weld toe has a significant effect on the fatigue strength of those weldments which show crack initiation at the toe. The present paper provides a discussion of the role of four geometrical parameters based on theoretical simulation. These parameters are (Fig. 1)

- 1.

The weld toe radius ρ,

- 2.

The flank angle α,

- 3.

The depth k of a secondary notch which can be an undercut but also another feature such as the roughness of the base plate (which remained from rolling) close to the fusion line, and

- 4.

The weld reinforcement h.

Note that there are at least two different options to define the angle at the weld toe. In IBESS and corresponding publications, the flank angle α is defined as shown in Fig. 1. In contrast, the complementary weld opening angle β is used, e.g., in ISO 5817.

Not considered by now is the weld width L. The simulations are based on the IBESS procedure, a brief introduction to which is given in [2], for detailed discussions see [3, 4]. A very brief introduction to some important aspects is given by the following points:

In order to apply fracture mechanics to fatigue strength determination, some major requirements have to be fulfilled:

- (a)

The so-called short crack stage of fatigue crack propagation must be adequately described. This includes a cyclic elastic–plastic crack driving force and the gradual build-up of the crack closure effects at that stage. In IBESS realised is (i) the analytical determination of a “plasticity-corrected” ∆Kp, based on the cyclic J integral ∆J, and (ii) the formulation of a transitional function from no crack closure at the beginning of crack propagation to the crack size-independent crack closure effect at the long crack stage. The latter is based on the so-called cyclic R curve, i.e. the dependency of the fatigue crack propagation threshold on crack extension ∆Kth at the short crack stage which mirrors the gradual build-up of the crack closure phenomenon.

- (b)

A method for determining the initial crack size ai is needed which is adequate for fatigue strength considerations. NDT methods cannot be used for this because ai is one or two orders of magnitude smaller than the detection limits of these. In IBESS, the initial crack size is defined by (i) the size of a semi-circular crack that just would arrest (or grow) at fatigue limit stress level or (ii) a pre-existing crack-like flaw, whichever is larger. The determination of a lower bound-ai has its rational justification in the observation that the fatigue limit is not given by crack initiation but by the arrest of the largest of a big number of until then propagable short cracks [5, 6].

- (c)

A problem on its own is that the weld toe geometry is not constant but varies along the toe. Since crack initiation will follow a weakest link principle, it will take place at the sites of the highest stresses with the consequence of multiple cracks at different positions [7]. Note that it is not only the stress concentration at surface but also the stress profile in wall thickness direction which defines the criticality of potential crack initiation sites. An example for the variation of the geometrical parameters is provided in Fig. 2. Thus, multiple crack propagation is a further characteristic, fracture mechanics has to cope with when weld toes come into play.

Examples for crack initiation sites are shown in Fig. 3 along the toe of a MAG butt weld made of S355NL steel. The cracks have been visualised by heat tinting at an early stage of propagation after about one third of the overall lifetime. Note that no undercuts existed but surface roughness features (micro-notches) from the rolling process of the base plates were found to act as crack initiation sites. Cracks were also initiated at welding ripple edges and in the weld seam at some distance from the toe, but the latter tended to arrest or soon to coalesce with the main crack, for details see [7].

Figure 4 shows examples of finite life IBESS analyses with variations of the four parameters toe radius ρ, flank angle α, weld reinforcement h and secondary notch depth k. These are taken from a former study of the authors in [7]. Note that the combinations of the parameters were arbitrarily chosen, however, within realistic limits in terms of practical application.

Examples for IBESS analyses investigating the effect of different weld toe geometry parameters on the fatigue life branch of the S–N curve; according to [7]

The present study follows a more systematic way. Although IBESS takes into account multiple crack propagation in a stochastic way, this option will not be applied here. Instead, the goal of this study is twofold: first, to identify trends of the geometry parameters with respect to the fatigue strength and, second, to identify analysis steps needed to make IBESS fruitful for the discussion about an improved weld quality class system. The latter requires some explanation.

The common quality standard system of welds as specified in ISO 5817:2014 [9] follows what might be called a ‘good workmanship’ principle. Not less than 41 different types of weld imperfections are listed not all of which have an effect of the fatigue behaviour. Hobbacher calls this ‘a congenital defect’ [10] and Björk et al. [11] comment: ‘The difficulty with the system is that the classification is ultimately based on the worst characteristic of the weld out of a long list of potential characteristics. Some of the characteristics in the ISO system have little or no influence on weld strength while some important characteristics are omitted’.

In order to improve this situation, proposals have been made to combine the ISO quality system with the FAT class approach developed within the IIW guideline [12] and equivalent approaches in documents such as the Eurocode [13] or the FKM guidelines [14]. As an example, the Volvo Standard STD 181-0004 [15] is based on eight parameters including the weld toe radius ρ, the flank angle α, weld reinforcement h and undercut depth k. Likewise, the 2014 update of ISO 5817 [9] contains an (informative) annex with additional requirements for fatigue which combine the ISO quality levels with IIW FAT classes 63, 90 and 125.

In the present paper, the IBESS approach is applied to determine FAT classes dependent on the weld toe parameters radius ρ, flank angle α, reinforcement h and secondary notch depth k. Because any number of combinations of these is possible, the investigation, in the first step, is restricted to just one parameter. The others are specified to be as little harmful as possible within IBESS, i.e. when investigating the secondary notch depth, the toe radius is set to 4 mm, the flank angle to 10° and the reinforcement to 0.75 mm as the highest respectively lowest values realised in IBESS. In addition, selected parameter combinations are investigated. As previously mentioned, statistical distributions of the parameters of the weld toe geometry and the material data are not considered.

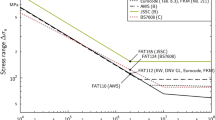

A FAT class is defined as the stress range at N = 2∙106 loading cycles (Fig. 5). Note that the different documents use the same set of curves, however, for different R ratios (IIW, R = 0.5; Eurocode, R = 0; FKM, R = −1) and compensate the discrepancy by different mean stress corrections [16]. The IIW document, we follow here, uses Eq. (1)

FAT class concept for steel (IIW guidelines [12])

for the case of negligible residual stresses (σr < 0.2σY) and non-thin-walled plates.

Within the present study, butt welds of steel S355NL with a base plate thickness of T = 10 mm are simulated whereby HAZ material parameters are used, for the latter see [17]. In terms of the IIW recommendations, the configurations refer to FAT class 90 (and perhaps 80).

With the IBESS procedure, individual IBESS FAT classes can be determined for different weld geometries. In order to fit the results into the FAT class concept of IIW, some subsequent conversion is necessary. This is because the IBESS results such as obtained in this study will be given as mean values (probability Ps = 50%) of stress amplitudes σa for a stress ratio of R = −1 whereas the conditions of the IIW FAT classes are Ps = 97.7%, stress range ∆σ and R = 0.5. Common to both versions is a number of loading cycles of N = 2∙106.

The conversion between stress amplitude and stress range is simply done by a factor of 2 since ∆σ = 2σa. The transfer between the different R ratios has strictly to follow the rules of the IIW FAT class system and uses Eq. (1). In order to convert the IBESS stress amplitude σa,IBESS obtained for Ps = 50% to Ps = 97.7%, the standard deviation s of a lognormal distribution is required. This can be derived from the scatter range 1/Tσ (see Eq. 2). Due to the lack of individual empirical data in this study, a scatter band of 1/Tσ = 1.28 according to Ritter [1] is used for the welded joints.

Note that in the literature alternative expressions for estimating scatter bands exist. For example, Haibach [18] gives a range of 1/Tσ = 1.45 (scatter between 10% and 90% survival probability curves) for professionally welded joints of mild steel under normal operating conditions with an S–N curve slope of 3. Lazzarin and Livieri [19] provide a value of 1.85, although for a deviating definition (between 2.3% and 97.7% survival probability) which corresponds to 1/Tσ = 1.48 in the present frame. In order to avoid confusion, only our estimate based on the Ritter compendium is shown in the figures below. Nevertheless, the subject matter calls for a discussion because the different approaches have a not negligible effect on the topic provided in this paper. For example, if the IBESS FAT class is calculated for 1/Tσ = 1.28 the result is 100 MPa, but it would be 9.25% lower, i.e. 90.75 MPa for 1/Tσ = 1.45. The point is that all the 1/Tσ solutions are not more than estimates. This of course makes it difficult to decide which result is correct in the end. What is, therefore needed is to compare the results of IBESS analyses to real scatter bands. This was outside the frame of the present study but it will certainly be needed in future work.

Note that the IBESS approach not always yields perfect descriptions of the S–N curves of weldments—while very good results were obtained in a number of cases in [3, 4] other results were conservative because of mean and/or residual stress effects which have not be considered, as the authors suspect. With respect to the cruciform joints and longitudinal gussets, a further source of conservatism is the application of weight functions for K factor determination based on a plate model with lower stiffness than those of the welded joints. The best matches of the IBESS simulations with the experimentally determined S–N curves were achieved for butt welds and an R-ratio of R = −1. Thus, the IBESS calculations in this paper were performed for this R-ratio and the conversion described above was necessary.

Despite this restriction, the IBESS simulation offers advantages especially for the task of this study in that the geometrical parameters can be modified independently of each other and in arbitrary combinations as long as geometrically possible. Not only, different to the experiments, undesirable factors of influence can be suppressed; since the effort is considerably lower, the gradation of the parameters can be chosen much finer.

2 Influence of the weld toe geometry on the FAT classes

2.1 Geometric variations and crack initiation sites

Before the influence of the different weld toe parameters on the FAT classes will be discussed, an empirical observation shall be placed in front. Figure 6 shows the statistical distributions of the parameters toe radius ρ, flank angle α, weld reinforcement h and secondary notch depth k as they have been determined by scanning the specimen surfaces with a 3D confocal microscope. Note that in any case two distributions are shown which are based on

- (d)

Measurements along the weld toe at equidistant sections (blue curves), and

- (e)

Measurements at the points where crack initiation could be stated (red curves).

Statistical distribution of the weld toe geometry parameters (a) radius ρ; (b) flank angle α; (c) reinforcement h; (d) secondary notch depth k; and (e) secondary notch geometry k/b. The blue and red curves refer to measurements at equidistant sections along the toe and at the points of crack initiation

Except Fig. 6d and e which refers to the secondary notch depth k and geometry k/b, the two distributions are nearly identical every time. However, a shift of the distribution peak is stated for k and k/b. What does that mean? It shows that cracks usually initiate at the deepest (Fig. 6d) and narrowest (Fig. 6e) secondary notches. That secondary notches such as undercuts are preferred fatigue crack initiation sites is well known from the literature, e.g. [20, 21]. Figure 7 shows a depth variation of undercuts along with the variation of the radius ρ along the toe, however, for cruciform joints of S355 steel. The undercut depth was found to vary from 0 to 0.7 mm with an average value of about 0.4 mm. Note that these values refer to a weld toe improved by an optimised gas-metal-arc-welding process but without post-weld treatment such as grinding. The data provide an impression but cannot be simply transferred to butt welds.

Variation of (a) the radius ρ and (b) the undercut depth k along the weld toe of a cruciform joint made of S355 steel; according to [22]

2.2 Weld toe radius ρ

Figure 8 shows the stress amplitudes calculated with the IBESS procedure, σa, IBESS, obtained for weld toe radii between ρ = 0.1 mm to 4 mm and the converted ‘IBESS FAT classes’ respectively IIW FAT classes for selected values. The flank angle α is chosen as 10° which is a fairly small value expected to be favourable in terms of fatigue strength, and the same is true with respect to the small weld reinforcement of h = 0.75 mm. As can be seen, the strongest increase of the FAT class occurs up to a radius of 1 mm (coming from smaller values) or, other way round, the parameter becomes increasingly detrimental below 1 mm.

However, this is true only for the blue curve where the secondary notch depth k is as small as 5 μm. When k = 0.48 mm is assumed (red curve), it shows up that variations in the toe radius have only a small effect on the fatigue strength which seems to be controlled almost exclusively by the secondary notch in that case. It has to be added here that the secondary notch is treated as part of the crack emanating from it. For a brief discussion of this issue, see Section 2.4.

2.3 Flank angle α

This time, the secondary notch depth and the weld reinforcement are set to the lowest values realised in IBESS: k = 5 μm and h = 0.75 mm. As expected, the FAT class becomes smaller with increasing flank angle, but there is no much additional effect beyond α = 20° to 30o with the transition depending on the toe radius ρ. The effect of the flank angle α on the FAT class increases for the lower weld toe radius of ρ = 0.1 mm as compared to ρ = 4 mm. That both parameters seem to interact with respect to the fatigue strength as shown in Fig. 9 should not be surprising since they can hardly be realised completely independently of each other. Both α and ρ affect the stress distribution in wall thickness direction, see, e.g. Fig. 2. The example here shows that a statement such as in [23], that a significant improvement of the fatigue strength is obtained when the flank angle is decreased below a value of 20°, though applicable also to our examples, should not be generalised when other geometry parameters come into play.

2.4 Secondary notch depth k

Smaller notches within larger ones are designated as ‘secondary’ in IBESS. The classic example is an undercut at the primary weld toe notch. As a side effect, this classification solves the problem of an adequate definition of the weld toe radius. Note that based, e.g., on surface scanning, quite different toe radii could be determined depending on the level of zooming [24]. In IBESS, the weld toe radius ρ is defined as the ‘primary’ notch while deviations from the idealised geometry, if large enough, form the secondary one, see Fig. 10.

In principle, secondary notches can be treated either as notches or as cracks in fracture mechanics. The problem when the latter option is expedient, is discussed e.g. in [4, 25] based on literature results. It turns out that the ratio of the crack depth at the secondary notch root and the radius of the latter, ai/ρ′, is a suitable measure for case distinction. The treatment as a crack is correct above a certain value of ai/ρ′ with a rough (and conservative) order of this being around unity. The authors in [26] report undercut radii between 0.25 and 0.76 mm for MIG welds and between 0.25 and 3.81 mm for TIG welds, however of cruciform joints. The authors in [27] found undercut radii between 0.4 and 1.2 mm. In [21], it is distinguished between three types of undercuts: (i) wide and curved, (ii) narrow or very narrow, even crack-like, and (iii) shallow and narrow with depths k up to about 0.25 mm. The size and geometry of type (ii) undercuts is difficult to determine under practical conditions. Furthermore, the potential existence of small cracks emanating from undercuts as shown, e.g., in [28], is usually not detectable under conditions of practice and should, therefore, not be excluded. Not least because of these uncertainties the treatment of an undercut as a crack will usually make sense. The following results have been obtained based on this assumption.

Frequently, undercuts are not continuous along the weld toe but intermittent with the consequence of some macro-support of the surrounding material. This, in principle, requires 3D instead of 2D analyses of the stress field. However, as shown in [29], the overestimation of the stress by 2D is rather moderate (in that case 5% to 10%).

Generally, it shows up that the secondary notch depth k has the biggest influence of the geometric parameters considered. As can be seen in Fig. 11, there is a rather moderate influence of the flank angle α between 10° and 30° when a large weld toe radius of ρ = 4 mm is chosen. However, this picture changes below a secondary notch depth of k = 0.2 to 0.3 mm for a toe radius of ρ = 0.1 mm (Fig. 12) in that the larger angle of α = 30° causes a stronger reduction of the ‘IBESS FAT class’. Again, these results provide an example of the interaction of different weld toe parameters with respect to the fatigue strength. They show that the various parameters, in the end, must not be treated individually but considered in their combination.

Notwithstanding this limitation, it can be seen in both Figs. 11 and 12 that a significant improvement of the fatigue strength is reached when the secondary notch depth is reduced below a value of k ≈0.05–0.1 mm. There is no doubt and it was shown in practical application that grinding undercuts will have a beneficial effect (e.g. [30]).

2.5 Weld reinforcement h

The investigation of the effect of the weld reinforcement h is shown for a rather ‘mild’ weld toe geometry (α = 10°, ρ = 4 mm) in Fig. 13 and for a sharper transition (α = 30°, ρ = 0.1 mm) in Fig. 14. The parameter was varied between h = 0.75 mm and 2.5 mm. Note that for reinforcements larger than 2.5 mm and for cruciform joints, a maximum value of h = 2.5 mm is used in IBESS [3, 4]. No reinforcement effect is stated in Fig. 13 for both a secondary notch depth k of 5 μm and 0.48 mm, and this is also the case for the deeper secondary notch (k = 0.48 mm) in Fig. 14, although there is a moderate effect in that the fatigue strength slightly increases for smaller h when the secondary notch does not play a role (k = 5 μm). In any case, the influence of h is much smaller than that of the other parameters investigated within this study.

3 Discussion

While the stress amplitudes referring to N = 2∙106 loading cycles, when compared to the IIW FAT class, are satisfactorily predicted by the IBESS method in case of defect sizes at the acceptance limits, particularly an undercut depth of 0.5 mm for FAT 90, the simulations show that improvements are possible by optimising the weld toe geometry. However, having a closer look at the results, these become significant only beyond certain limits such as a flank angle smaller than a = 20°–25° (Fig. 9) or an undercut depth smaller than k = 0.1 mm (Figs. 11 and 12). The weld toe radius seems to have a larger effect only in the range up to ρ = 1 mm (Fig. 8). That raises the question whether significant improvements can be reached with realistic effort in practical application—a discussion which cannot be provided here; see, however, the recommendations in [31].

What, however, can be stated is that the IBESS method is shown to be a suitable tool for identifying the parameter ranges within which a significant improvement of the fatigue strength can be expected. While in the present work only selective examples are provided, a much more systematic application with respect to different combinations of the parameters including the statistical characteristics of these will be the aim of future investigations.

A critical remark is due with respect to the results obtained for very smooth weld toes, i.e. a secondary notch depth of 5 μm, a weld toe radius of 4 mm and a flank angle of 10° in the present case. Beyond a certain limit, these become unrealistic. Assume a perfectly smooth butt weld due to machining the surface after welding. For the S355NL steel considered here, the maximum fatigue strength (amplitude) at R = −1 which can be reached is that of the base metal, which was about 275 MPa (according to Kucharczyk et al. [17]), and this is also the upper limit with respect to the butt welds investigated. Interestingly, this refers to the highest values obtained at the ‘IBESS FAT class’ level in the present simulations.

Nevertheless, these values should be distrusted. Why? At the completely smooth surface, the geometrical notch is removed. What is left is the ‘metallurgical’ notch at the transition between the higher strength HAZ and the lower strength base metal with the last one controlling the fatigue behaviour of the component. In contrast, crack initiation and initial crack propagation was assumed throughout at the geometrical notch, i.e. the weld toe, in the present simulations. That means that the fatigue strength-controlling early crack propagation always took place in HAZ material. Consequently, all IBESS calculations have been performed with HAZ properties which were superior to those of the base metal, e.g. the fatigue strength amplitude at R = −1 was 400 MPa or more; for details, see Kucharczyk et al. [17].

4 Summary and outlook

The present study has dealt with the fatigue class of butt welds with crack initiation at the weld toe. The effect of the geometry parameters toe radius ρ, flank angle α, reinforcement h and secondary notch depth k on the ‘IBESS FAT class’, i.e. stress range for N = 2∙106, R = 0.5 and Ps = 97.7% (in analogy to the IIW FAT-class) has been investigated by means of some conversions and the IBESS approach of the authors which provides a theoretical fracture mechanics tool for fatigue strength prediction. The study was organised such that (i) first, each parameter was investigated individually choosing the others as little harmful as possible within IBESS, and (ii) second, selected parameter combinations were evaluated. Statistical distributions of the geometry parameters and the material data were ignored.

The outcome of the simulations allowed a rough ranking of the parameters with respect to their effect on the fatigue strength. As the most influential parameter, the secondary notch depth k (e.g. an undercut) turned out, followed by the flank angle α and the toe radius ρ. The weld reinforcement played a minor role within the limits of the investigation. However, it also showed up that the effects of the individual parameters were heavily overlaid by others when considered in combination. Again, the secondary notch depth played the most significant role but there were effects of the toe radius and flank angle as well.

The results of the analyses were compared to the FAT class approach of IIW. Both concepts seem to fit together. That opens up the possibility to make the IBESS approach fruitful for the present discussion about an improved weld quality class system. The advantages of theoretical simulation in contrast and in addition to experimental work are (i) the option to vary single parameters and parameter combinations within a wide frame and (ii) to choose a fine graduation of the parameters.

There are, however, also open points and problems which have to be solved to that purpose. One of those is not taking into account the influences of the statistical distributions of the geometry parameters along the weld toe and the associated multiple fatigue crack initiation and early propagation at various sites along the weld toe. This causes most of the scatter in fatigue strength known for welded components. IBESS is able to model these effects and to provide the fatigue strength in terms of a statistical distribution.

Note that another point is that the survival probability of 97.7% on which the IIW FAT classes are based constitute another problem at the present state. The applied scatter band rests on one estimate out of a number of possible options which, of course, relates to the results. The consequence is that analyses based on empirical scatter bands will be necessary in the future.

The possibility of far-reaching variations of the weld toe geometry in theoretical simulation also provides the possibility for geometry optimisation in that it can show below or above which limits the improvement of one geometry parameter makes sense when the other parameters are given, respectively which parameter combinations should be aimed at.

Abbreviations

- a :

-

Crack depth

- a i :

-

Initial crack depth (for fracture mechanics analysis)

- b :

-

Secondary notch width

- B :

-

Plate width, length of the weld toe

- f(R):

-

Mean stress correction function.

- h :

-

Weld reinforcement

- k :

-

Secondary notch depth

- k t :

-

Stress concentration factor at surface (=σ/σN)

- K max :

-

Maximum K-factor in a loading cycle

- K min :

-

Minimum K-factor in a loading cycle

- L :

-

Weld width

- N :

-

Number of loading cycles

- N c :

-

Number of loading cycles up to fracture

- P s :

-

Probability of survival

- R :

-

Stress ratio (σmin/σmin or Kmin/Kmax)

- s :

-

Standard deviation (lognormal distribution)

- T :

-

Thickness of the base plate

- T σ :

-

Range of scatter of stress (Tσ = σa,90%/σa,10%)

- α :

-

Weld flank angle

- β :

-

Weld opening angle (complementary of the weld flank angle (β = 180° − α), e.g. in accordance with DIN EN ISO 5817)

- ΔJ :

-

Cyclic J-integral (cyclic loading)

- ΔK :

-

K-factor range (Kmax − Kmin)

- ΔKp :

-

Plasticity-corrected K factor obtained as \( \varDelta {K}_{\mathrm{p}}=\sqrt{\varDelta J\cdot E} \)

- Δσ :

-

Stress range (σmax–σmin)

- ΔσFAT :

-

FAT-class; stress range for N = 2∙106, R = 0.5 and Ps = 97.7% (IIW definition)

- ΔσFAT,IBESS :

-

IBESS FAT-class; stress range calculated with IBESS under the assumption of a lognormal distribution with a scatter band Tσ referred to Ritter [1] and under consideration of the mean stress correction function f(R) according to IIW, defined for N = 2∙106, R = 0.5 and Ps = 97.7% (in analogy to the IIW FAT-class)

- ρ :

-

Weld toe radius

- ρ′:

-

Radius of secondary notch root

- σ :

-

Stress

- σ a :

-

Stress amplitude (=½ ∙ (σmax − σmin))

- σ a,90% :

-

Stress amplitude at a probability of survival of 90%

- σ a,IBESS :

-

Stress amplitude calculated with IBESS for N = 2∙106, R = −1 and Ps = 50%

- σ max :

-

Maximum stress in a loading cycle

- σ min :

-

Minimum stress in a loading cycle

- σ N :

-

Net section stress (referred to base plate)

- σ r :

-

Residual stresses

- σ y :

-

Maximum principal stress

- σ Y :

-

Yield strength

- FAT:

-

stress range ∆σ referring to 2∙106 loading cycles

- HAZ:

-

heat affected zone

- IBESS:

-

acronym (German) standing for “Integral fracture mechanics determination of the fatigue strength of welds”

- IIW:

-

International Institute of Welding

- ISO:

-

International Organization for Standardization

- MAG:

-

metal active gas welding

- MIG:

-

metal inert gas welding

- NDT:

-

non-destructive testing

- TIG:

-

tungsten inert gas arc welding

References

Ritter W (1994) Kenngrößen der Wöhlerlinien für Schweißverbindungen aus Stahl. Report No. 53 of the Institut für Stahlbau und Werkstoffmechanik, TH Darmstadt, in German

Zerbst U (2020) Application of fracture mechanics to welds with crack origin at the weld toe—a review. Part 2: welding residual stresses. Residual and total life assessment. Weld World 64:151–169

Zerbst U, Savaidis G, Beier HT (eds) (2018) Special issue on fracture mechanics-based determination of the fatigue strength of weldments. Eng Fract Mech 198:1–208

Zerbst U, Madia M, Schork B, Hensel J, Kucharczyk P, Tchoffo Ngoula D, Tchuindjang D, Bernhard J, Beckmann C (2019) Fatigue and fracture of weldments. The IBESS approach for the determination of the fatigue life and strength of weldments by fracture mechanics analysis. Springer Nature Switzerland, Cham

Miller KJ (1993) The two thresholds of fatigue behaviour. Fatigue Fract Eng Mater Struct 16:931–939

Murakami Y (2002) Metal fatigue. Effects of small defects and nonmetallic inclusions. Elsevier, Oxford

Schork B, Kucharczyk P, Madia M, Zerbst U, Hensel J, Bernhard J, Tchuindjang D, Kaffenberger M, Oechsner M (2018) The effect of the local and global weld geometry as well as material defects on crack initiation and fatigue strength. Eng Fract Mech 198:103–122

Verreman Y, Nie B (1991) Short crack growth and coalescence along the toe of a manual fillet weld. Fatigue Fract Eng Mater Struct 14:1337–1349

ISO 5817 (2014) Welding—Fusion welded joints in steel, nickel, titanium and their alloys (beam welding excluded)—Quality levels for imperfections. International Organisation for Standardization (ISO), Geneva

Hobbacher A (2009) The new IIW recommendations for fatigue assessment of welded joints and components—a comprehensive code recently updated. Int J Fatigue 31:50–58

Björk T, Samuelsson J, Marquis G (2008) The need for a weld quality system for fatigue loaded structures. Weld World 52:34–46

Hobbacher AF (2016) Recommendations for fatigue design of welded joints and components (IIW collection). Springer Int. Publ, Heidelberg

Eurocode 3 (2005) Design of steel structures, Part 1–9: Fatigue

Richtlinie FKM (2005) Rechnerischer Festigkeitsnachweis für Maschinenbauteile aus Stahl, Eisenguss- und Aluminiumwerkstoffen, VDMA Verlag, 5. Ausgabe

VOLVO Standard STD 181-0004. Volvo Group Weld Quality Standard, 2008

Kaffenberger M (2012) Schwingfestigkeit von Schweißverbindungen und Übertragbarkeit von Schweißverbindungswöhlerlinien. Report No. 97 of the Institut für Stahlbau und Werkstoffmechanik, TU Darmstadt, in German

Kucharczyk P, Madia M, Zerbst U, Schork B, Gerwin P, Münstermann S (2018) Fracture-mechanics based prediction of the fatigue strength of weldments. Material aspects. Eng Fract Mech 198:79–102

Haibach E (1989) Service fatigue-strength-methods and data for structural analysis. VDI, Düsseldorf, p 527 in German

Lazzarin P, Livieri P (2001) Notch stress intensity factors and fatigue strength of aluminum and steel welded joints. Int J Fatigue 23:225–232

Harati E, Karlsson L, Svensson LE, Dalaei K (2015) The relative effects of residual stresses and weld toe geometry on fatigue life of weldments. Int J Fatigue 77:160–165

Balasubramanian V, Guha B, Swamidas ASJ, Seshadri R (2000) Influences of shielded metal arc welded cruciform joint dimensions on toe crack failures of pressure vessel grade steels. Eng Fail Anal 7:169–179

Åstrand E, Stenberg T, Jonsson B, Barsoum Z (1016) Welding procedures for fatigue life improvement of the weld toe. Weld World 60:573–580

Ninh Nguyen T, Wahab MA (1995) A theoretical study of the effect of weld geometry parameters on fatigue crack propagation life. Eng Fract Mech 51:1–18

Lindgren E, Stenberg T (2011) Quality inspection and fatigue assessment of welded structures. Master Thesis, KTH Enging. Sci., Stockholm

Madia M, Zerbst U, Beier HT, Schork B (2018) The IBESS model—elements, realisation and validation. Eng Fract Mech 198:171–208

Mashiri FR, Zhao XL, Grundy P (2001) Effects of weld profile and undercut on fatigue crack propagation life of thin-walled cruciform joint. Thin-Walled Struct 39:261–285

Janosch JJ, Debiez S (1998) Influence of the shape of undercut on the fatigue strength of fillet welded assemblies—application of the local approach. Weld World 41(2):350–360

Liinalampi S, Remes H, Romanoff J. Influence of three-dimensional weld undercut geometry on fatigue-effective stress. Weld World 2018;

Lieurade HP, Huther I, Lefebvre F (2008) Effect of weld quality and postweld improvement techniques on the fatigue resistance of extra high strength steels. Weld World Res Supp 52:106–115

Hansen AV, Agerskov H, Bjornbak-Hansen J (2007) Improvement of fatigue life of welded structural components by grinding. Weld World 51:61–67

Haagensen PJ, Maddox SJ (2006) IIW recommendations on post weld improvement of steel and aluminium structures. International Institute of Welding (IIW), Commission XIII, XIII-1815-00

Acknowledgements

Open Access funding provided by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

B. Schork and M. Kaffenberger was formerly affiliated to Zentrum für Konstruktionswerkstoffe – Staatliche Materialprüfungsanstalt Darmstadt (MPA), Technische Universität Darmstadt. The work was done while they were at MPA Darmstadt.

Recommended for publication by Commission XIII - Fatigue of Welded Components and Structures

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Schork, B., Zerbst, U., Kiyak, Y. et al. Effect of the parameters of weld toe geometry on the FAT class as obtained by means of fracture mechanics-based simulations. Weld World 64, 925–936 (2020). https://doi.org/10.1007/s40194-020-00874-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-00874-7