Abstract

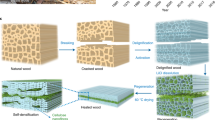

The complex structure of wood, one of the most abundant biomaterials on Earth, has been optimized over 270 million years of tree evolution. This optimization has led to the highly efficient water and nutrient transport, mechanical stability and durability of wood. The unique material structure and pronounced anisotropy of wood endows it with an array of remarkable properties, yielding opportunities for the design of functional materials. In this Review, we provide a materials and structural perspective on how wood can be redesigned via structural engineering, chemical and/or thermal modification to alter its mechanical, fluidic, ionic, optical and thermal properties. These modifications enable a diverse range of applications, including the development of high-performance structural materials, energy storage and conversion, environmental remediation, nanoionics, nanofluidics, and light and thermal management. We also highlight advanced characterization and computational-simulation approaches for understanding the structure–property–function relationships of natural and modified wood, as well as informing bio-inspired synthetic designs. In addition, we provide our perspective on the future directions of wood research and the challenges and opportunities for industrialization.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Food and Agriculture Organization of the United Nations. Global production and trade of forest products in 2018. FAO http://www.fao.org/forestry/statistics/80938/en/ (2018).

Wimmers, G. Wood: a construction material for tall buildings. Nat. Rev. Mater. 2, 17051 (2017).

Balat, M. & Bozbas, K. Wood as an energy source: potential trends, usage of wood, and energy politics. Energ. Source. Part A 28, 837–844 (2006).

Sjostrom, E. Wood Chemistry: Fundamentals and Applications (Elsevier, 1993).

Ling, S., Kaplan, D. L. & Buehler, M. J. Nanofibrils in nature and materials engineering. Nat. Rev. Mater. 3, 18016 (2018).

Zhu, H. et al. Wood-derived materials for green electronics, biological devices, and energy applications. Chem. Rev. 116, 9305–9374 (2016).

Gibson, L. J., Ashby, M. F. & Harley, B. A. Cellular Materials in Nature and Medicine (Cambridge Univ. Press, 2010).

Meyers, M. A., Chen, P.-Y., Lin, A. Y.-M. & Seki, Y. Biological materials: structure and mechanical properties. Prog. Mater. Sci. 53, 1–206 (2008).

Fratzl, P. & Weinkamer, R. Nature’s hierarchical materials. Prog. Mater. Sci. 52, 1263–1334 (2007).

Fahlén, J. & Salmén, L. Cross-sectional structure of the secondary wall of wood fibers as affected by processing. J. Mater. Sci. 38, 119–126 (2003).

Berglund, L. A. & Burgert, I. Bioinspired wood nanotechnology for functional materials. Adv. Mater. 30, 1704285 (2018).

Hill, C. A. S. Wood Modification: Chemical, Thermal and Other Processes Vol. 5 (John Wiley & Sons, 2007).

Evans, P. D., Michell, A. J. & Schmalzl, K. J. Studies of the degradation and protection of wood surfaces. Wood Sci. Technol. 26, 151–163 (1992).

Evans, P., Matsunaga, H. & Kiguchi, M. Large-scale application of nanotechnology for wood protection. Nat. Nanotechnol. 3, 577 (2008).

Hill, C. A. S. Wood modification: An update. BioResources 6, 918–919 (2011).

Rowell, R. M. in Handbook of Engineering Biopolymers, Homopolymers, Blends, and Composites (eds Fakirov, S. & Bhattacharyya, D.) 673–691 (Hanser Gardner Publications, 2007).

Homan, W. J. & Jorissen, A. J. Wood modification developments. Heron 49, 360–369 (2004).

Esteves, B. & Pereira, H. Wood modification by heat treatment: a review. BioResources 4, 370–404 (2008).

Fuchs, W. Genuine lignin. I. Acetylation of pine wood. Ber. Deutsch. Chem. Gesellsch. B 61, 948–951 (1928).

Lande, S., Westin, M. & Schneider, M. Properties of furfurylated wood. Scand. J. For. Res. 19, 22–30 (2004).

Fujimura, T., Uemura, I. & Inoue, M. Study on the high durability of wood with acryl high polymer (I). Interaction between wood and acryl high polymer. Wood Protect. 15, 62–71 (1989).

Jiang, F. et al. Wood-based nanotechnologies toward sustainability. Adv. Mater. 30, 1703453 (2018).

Fu, Q., Ansari, F., Zhou, Q. & Berglund, L. A. Wood nanotechnology for strong, mesoporous, and hydrophobic biocomposites for selective separation of oil/water mixtures. ACS Nano 12, 2222–2230 (2018).

Li, T. et al. Cellulose ionic conductors with high differential thermal voltage for low-grade heat harvesting. Nat. Mater. 18, 608–613 (2019).

Guan, H., Cheng, Z. & Wang, X. Highly compressible wood sponges with a spring-like lamellar structure as effective and reusable oil absorbents. ACS Nano 12, 10365–10373 (2018).

Zhu, M. et al. Highly anisotropic, highly transparent wood composites. Adv. Mater. 28, 5181–5187 (2016).

Foster, E. J. et al. Current characterization methods for cellulose nanomaterials. Chem. Soc. Rev. 47, 2609–2679 (2018).

Utsumi, Y., Sano, Y., Fujikawa, S., Funada, R. & Ohtani, J. Visualization of cavitated vessels in winter and refilled vessels in spring in diffuse-porous trees by cryo-scanning electron microscopy. Plant. Physiol. 117, 1463–1471 (1998).

Gierlinger, N., Keplinger, T. & Harrington, M. Imaging of plant cell walls by confocal Raman microscopy. Nat. Protoc. 7, 1694–1708 (2012).

Agarwal, U. P. Raman imaging to investigate ultrastructure and composition of plant cell walls: distribution of lignin and cellulose in black spruce wood (Picea mariana). Planta 224, 1141 (2006).

Zlotnikov, I., Zolotoyabko, E. & Fratzl, P. Nano-scale modulus mapping of biological composite materials: Theory and practice. Prog. Mater. Sci. 87, 292–320 (2017).

Saito, K. et al. Direct mapping of morphological distribution of syringyl and guaiacyl lignin in the xylem of maple by time-of-flight secondary ion mass spectrometry. Plant. J. 69, 542–552 (2012).

Plaza, N. Z., Pingali, S. V., Qian, S., Heller, W. T. & Jakes, J. E. Informing the improvement of forest products durability using small angle neutron scattering. Cellulose 23, 1593–1607 (2016).

Fernandes, A. N. et al. Nanostructure of cellulose microfibrils in spruce wood. Proc. Natl Acad. Sci. USA 108, E1195–E1203 (2011).

Zhu, H. et al. Anomalous scaling law of strength and toughness of cellulose nanopaper. Proc. Natl Acad. Sci. USA 112, 8971–8976 (2015).

Schmidt, J. & Kaliske, M. Models for numerical failure analysis of wooden structures. Eng. Struct. 31, 571–579 (2009).

Yano, H., Hirose, A. & Inaba, S. High-strength wood-based materials. J. Mater. Sci. Lett. 16, 1906–1909 (1997).

Donaldson, L. A. Lignification and lignin topochemistry — an ultrastructural view. Phytochemistry 57, 859–873 (2001).

Barnett, J. R. & Bonham, V. A. Cellulose microfibril angle in the cell wall of wood fibres. Biol. Rev. 79, 461–472 (2004).

Weinkamer, R. & Fratzl, P. Mechanical adaptation of biological materials—The examples of bone and wood. Mater. Sci. Eng. C 31, 1164–1173 (2011).

Gordon, J. E. & Mattis, D. C. in The New Science of Strong Materials, or, Why You Don’t Fall Through the Floor (AAPT, 1985).

Fang, C.-H., Mariotti, N., Cloutier, A., Koubaa, A. & Blanchet, P. Densification of wood veneers by compression combined with heat and steam. Eur. J. Wood Prod. 70, 155–163 (2012).

Bekhta, P., Hiziroglu, S. & Shepelyuk, O. Properties of plywood manufactured from compressed veneer as building material. Mater. Des. 30, 947–953 (2009).

Parˇil, P. et al. Comparison of selected physical and mechanical properties of densified beech wood plasticized by ammonia and saturated steam. Eur. J. Wood Prod. 72, 583–591 (2014).

Keplinger, T. et al. A versatile strategy for grafting polymers to wood cell walls. Acta Biomater. 11, 256–263 (2015).

Vitas, S., Keplinger, T., Reichholf, N., Figi, R. & Cabane, E. Functional lignocellulosic material for the remediation of copper (II) ions from water: towards the design of a wood filter. J. Hazard. Mater. 355, 119–127 (2018).

Chen, F. et al. Mesoporous, three-dimensional wood membrane decorated with nanoparticles for highly efficient water treatment. ACS Nano 11, 4275–4282 (2017).

Zhu, M. et al. Plasmonic wood for high-efficiency solar steam generation. Adv. Energy Mater. 8, 1701028 (2018).

Li, T. et al. Anisotropic, lightweight, strong, and super thermally insulating nanowood with naturally aligned nanocellulose. Sci. Adv. 4, eaar3724 (2018).

Li, T. et al. A nanofluidic ion regulation membrane with aligned cellulose nanofibers. Sci. Adv. 5, eaau4238 (2019).

Song, J. et al. Highly compressible, anisotropic aerogel with aligned cellulose nanofibers. ACS Nano 12, 140–147 (2018).

Song, J. et al. Superflexible wood. ACS Appl. Mater. Interfaces 9, 23520–23527 (2017).

Kawamata, Y. et al. Kinetic analysis of delignification of cedar wood during organosolv treatment with a two-phase solvent using the unreacted-core model. Chem. Eng. J. 368, 71–78 (2019).

Shen, F. et al. Ultra-thick, low-tortuosity, and mesoporous wood carbon anode for high-performance sodium-ion batteries. Adv. Energy Mater. 6, 1600377 (2016).

Ermeydan, M. A., Cabane, E., Hass, P., Koetz, J. & Burgert, I. Fully biodegradable modification of wood for improvement of dimensional stability and water absorption properties by poly (ε-caprolactone) grafting into the cell walls. Green Chem. 16, 3313–3321 (2014).

Cabane, E., Keplinger, T., Künniger, T., Merk, V. & Burgert, I. Functional lignocellulosic materials prepared by ATRP from a wood scaffold. Sci. Rep. 6, 31287 (2016).

Cabane, E., Keplinger, T., Merk, V., Hass, P. & Burgert, I. Renewable and functional wood materials by grafting polymerization within cell walls. ChemSusChem 7, 1020–1025 (2014).

Trey, S., Jafarzadeh, S. & Johansson, M. In situ polymerization of polyaniline in wood veneers. ACS Appl. Mater. Interfaces 4, 1760–1769 (2012).

Donath, S., Militz, H. & Mai, C. Wood modification with alkoxysilanes. Wood Sci. Technol. 38, 555–566 (2004).

Kong, L., Guan, H. & Wang, X. In situ polymerization of furfuryl alcohol with ammonium dihydrogen phosphate in poplar wood for improved dimensional stability and flame retardancy. ACS Sustain. Chem. Eng. 6, 3349–3357 (2018).

Merk, V., Chanana, M., Gaan, S. & Burgert, I. Mineralization of wood by calcium carbonate insertion for improved flame retardancy. Holzforschung 70, 867–876 (2016).

Shin, Y., Liu, J., Chang, J. H., Nie, Z. & Exarhos, G. J. Hierarchically ordered ceramics through surfactant-templated sol-gel mineralization of biological cellular structures. Adv. Mater. 13, 728–732 (2001).

Song, J. et al. Processing bulk natural wood into a high-performance structural material. Nature 554, 224–228 (2018).

Li, Y. et al. Lignin-retaining transparent wood. ChemSusChem 10, 3445–3451 (2017).

He, S. et al. An energy-efficient, wood-derived structural material enabled by pore structure engineering towards building efficiency. Small Methods 4, 1900747 (2020).

Kong, W. et al. Muscle-inspired highly anisotropic, strong, ion-conductive hydrogels. Adv. Mater. 30, 1801934 (2018).

Chen, C. et al. All-wood, low tortuosity, aqueous, biodegradable supercapacitors with ultra-high capacitance. Energy Environ. Sci. 10, 538–545 (2017).

Keckes, J. et al. Cell-wall recovery after irreversible deformation of wood. Nat. Mater. 2, 810–813 (2003).

Guindos, P. & Guaita, M. A three-dimensional wood material model to simulate the behavior of wood with any type of knot at the macro-scale. Wood Sci. Technol. 47, 585–599 (2013).

Glass, S. V. & Zelinka, S. L. in Wood Handbook: Wood as an Engineering Material Ch. 4 (US Dept. Agriculture, Forest Service, Forest Products Laboratory, 2010).

Holbrook, N. M. Transporting water to the tops of trees. Phys. Today 61, 76–77 (2008).

McCulloh, K. A., Sperry, J. S. & Adler, F. R. Water transport in plants obeys Murray’s law. Nature 421, 939–942 (2003).

Li, Y., Vasileva, E., Sychugov, I., Popov, S. & Berglund, L. Optically transparent wood: Recent progress, opportunities, and challenges. Adv. Opt. Mater. 6, 1800059 (2018).

Ross, R. J. (ed.) Wood Handbook: Wood as an Engineering Material (US Dept. Agriculture, Forest Service, Forest Products Laboratory, 2010).

Gustavsson, L. & Sathre, R. Variability in energy and carbon dioxide balances of wood and concrete building materials. Build. Environ. 41, 940–951 (2006).

Brandner, R., Flatscher, G., Ringhofer, A., Schickhofer, G. & Thiel, A. Cross laminated timber (CLT): overview and development. Eur. J. Wood Prod. 74, 331–351 (2016).

Mora Mendez, D. F. et al. Mechanical behavior of chemically modified Norway spruce: a generic hierarchical model for wood modifications. Wood Sci. Technol. 53, 447–467 (2019).

Niska, K. O. & Sain, M. Wood-Polymer Composites (Elsevier, 2008).

Csizmadia, R., Faludi, G., Renner, K., Móczó, J. & Pukánszky, B. PLA/wood biocomposites: Improving composite strength by chemical treatment of the fibers. Compos. Part A Appl. Sci. Manuf. 53, 46–53 (2013).

Stamm, A. J. & Seborg, R. M. Forest Products Laboratory Resin-Treated, Laminated, Compressed Wood (Compreg) (US Dept. of Agriculture, Forest Service, 1960).

Laine, K. et al. Measuring the thickness swelling and set-recovery of densified and thermally modified Scots pine solid wood. J. Mater. Sci. 48, 8530–8538 (2013).

Kamke, F. A. Densified radiata pine for structural composites. Maderas. Cienc. y. Tecnología 8, 83–92 (2006).

Shams, M. I., Yano, H. & Endou, K. Compressive deformation of wood impregnated with low molecular weight phenol formaldehyde (PF) resin I: effects of pressing pressure and pressure holding. J. Wood Sci. 50, 337–342 (2004).

Shams, M. I., Yano, H. & Endou, K. Compressive deformation of wood impregnated with low molecular weight phenol formaldehyde (PF) resin III: effects of sodium chlorite treatment. J. Wood Sci. 51, 234–238 (2005).

Frey, M. et al. Delignified and densified cellulose bulk materials with excellent tensile properties for sustainable engineering. ACS Appl. Mater. Interfaces 10, 5030–5037 (2018).

Zhu, M. et al. Anisotropic, transparent films with aligned cellulose nanofibers. Adv. Mater. 29, 1606284 (2017).

Jia, C. et al. Scalable, anisotropic transparent paper directly from wood for light management in solar cells. Nano Energy 36, 366–373 (2017).

Frey, M. et al. Tunable wood by reversible interlocking and bioinspired mechanical gradients. Adv. Sci. 6, 1802190 (2019).

Gibson, L. J. The hierarchical structure and mechanics of plant materials. J. R. Soc. Interface 9, 2749–2766 (2012).

Ashby, M. F. Materials Selection in Mechanical Design (Butterworth-Heinemann, 2011).

Garcia, M., Hidalgo, J., Garmendia, I. & García-Jaca, J. Wood–plastics composites with better fire retardancy and durability performance. Compos. Part A Appl. Sci. Manuf. 40, 1772–1776 (2009).

Guo, H. et al. Bioinspired struvite mineralization for fire resistant wood. ACS Appl. Mater. Interfaces 11, 5427–5434 (2019).

Liu, J. et al. Hexagonal boron nitride nanosheets as high-performance binder-free fire-resistant wood coatings. Small 13, 1602456 (2017).

Carosio, F., Cuttica, F., Medina, L. & Berglund, L. A. Clay nanopaper as multifunctional brick and mortar fire protection coating—wood case study. Mater. Des. 93, 357–363 (2016).

Plackett, D. V., Dunningham, E. A. & Singh, A. P. Weathering of chemically modified wood. Holz als Roh-und Werkst. 50, 135 (1992).

Gan, W. et al. Dense, self-formed char layer enables a fire-retardant wood structural material. Adv. Funct. Mater. 29, 1807444 (2019).

Merk, V., Chanana, M., Keplinger, T., Gaan, S. & Burgert, I. Hybrid wood materials with improved fire retardance by bio-inspired mineralisation on the nano- and submicron level. Green Chem. 17, 1423–1428 (2015).

Fu, Q. et al. Nanostructured wood hybrids for fire-retardancy prepared by clay impregnation into the cell wall. ACS Appl. Mater. Interfaces 9, 36154–36163 (2017).

Rowell, R. M., Ibach, R. E., McSweeny, J. & Nilsson, T. Understanding decay resistance, dimensional stability and strength changes in heat-treated and acetylated wood. Wood Mater. Sci. Eng. 4, 14–22 (2009).

Maier, J. Nanoionics: ion transport and electrochemical storage in confined systems. Nat. Mater. 4, 805–815 (2005).

Chen, C., Kuang, Y. & Hu, L. Challenges and opportunities for solar evaporation. Joule 3, 683–718 (2019).

Stein, D., Kruithof, M. & Dekker, C. Surface-charge-governed ion transport in nanofluidic channels. Phys. Rev. Lett. 93, 035901 (2004).

Weigl, B. H. & Yager, P. Microfluidic diffusion-based separation and detection. Science 283, 346–347 (1999).

Jia, C. et al. Anisotropic, mesoporous microfluidic frameworks with scalable, aligned cellulose nanofibers. ACS Appl. Mater. Interfaces 10, 7362–7370 (2018).

Pendergast, M. M. & Hoek, E. M. A review of water treatment membrane nanotechnologies. Energy Environ. Sci. 4, 1946–1971 (2011).

Chen, C. et al. Na+ intercalation pseudocapacitance in graphene-coupled titanium oxide enabling ultra-fast sodium storage and long-term cycling. Nat. Commun. 6, 6929 (2015).

Jakes, J. E. Mechanism for diffusion through secondary cell walls in lignocellulosic biomass. J. Phys. Chem. B 123, 4333–4339 (2019).

Chen, C. & Hu, L. Nanocellulose toward advanced energy storage devices: structure and electrochemistry. Acc. Chem. Res. 51, 3154–3165 (2018).

Chen, C. et al. Nature-inspired tri-pathway design enabling high-performance flexible Li–O2 batteries. Adv. Energy Mater. 9, 1802964 (2019).

Peng, X. et al. Hierarchically porous carbon plates derived from wood as bifunctional ORR/OER electrodes. Adv. Mater. 31, 1900341 (2019).

Zhang, Y. et al. High-capacity, low-tortuosity, and channel-guided lithium metal anode. Proc. Natl Acad. Sci. USA 114, 3584–3589 (2017).

Luo, W. et al. Encapsulation of metallic Na in an electrically conductive host with porous channels as a highly stable Na metal anode. Nano Lett. 17, 3792–3797 (2017).

Chen, C. et al. Highly conductive, lightweight, low-tortuosity carbon frameworks as ultrathick 3D current collectors. Adv. Energy Mater. 7, 1700595 (2017).

Li, Y. et al. Enabling high-areal-capacity lithium–sulfur batteries: designing anisotropic and low-tortuosity porous architectures. ACS Nano 11, 4801–4807 (2017).

Song, H. et al. Hierarchically porous, ultrathick, “breathable” wood-derived cathode for lithium-oxygen batteries. Adv. Energy Mater. 8, 1701203 (2018).

Wang, Y. et al. Wood-derived hierarchically porous electrodes for high-performance all-solid-state supercapacitors. Adv. Funct. Mater. 28, 1806207 (2018).

Tang, Z. et al. Highly anisotropic, multichannel wood carbon with optimized heteroatom doping for supercapacitor and oxygen reduction reaction. Carbon 130, 532–543 (2018).

Xu, S. et al. Flexible lithium–CO2 battery with ultrahigh capacity and stable cycling. Energy Environ. Sci. 11, 3231–3237 (2018).

Cheremisinoff, N. P. Handbook of Water and Wastewater Treatment Technologies (Butterworth-Heinemann, 2002).

Khawaji, A. D., Kutubkhanah, I. K. & Wie, J.-M. Advances in seawater desalination technologies. Desalination 221, 47–69 (2008).

Che, W. et al. Wood-based mesoporous filter decorated with silver nanoparticles for water purification. ACS Sustain. Chem. Eng. 7, 5134–5141 (2019).

Wang, K. et al. Two-dimensional membrane and three-dimensional bulk aerogel materials via top-down wood nanotechnology for multibehavioral and reusable oil/water separation. Chem. Eng. J. 371, 769–780 (2019).

Bai, X. et al. Facile fabrication of superhydrophobic wood slice for effective water-in-oil emulsion separation. Sep. Purif. Technol. 210, 402–408 (2019).

Zhu, M. et al. Tree-inspired design for high-efficiency water extraction. Adv. Mater. 29, 1704107 (2017).

Xue, G. et al. Robust and low-cost flame-treated wood for high-performance solar steam generation. ACS Appl. Mater. Interfaces 9, 15052–15057 (2017).

Liu, H. et al. High-performance solar steam device with layered channels: artificial tree with a reversed design. Adv. Energy Mater. 8, 1701616 (2018).

Wang, Y. et al. All natural, high efficient groundwater extraction via solar steam/vapor generation. Adv. Sustain. Syst. 3, 1800055 (2019).

Jia, C. et al. Rich mesostructures derived from natural woods for solar steam generation. Joule 1, 588–599 (2017).

Liu, K.-K. et al. Wood–graphene oxide composite for highly efficient solar steam generation and desalination. ACS Appl. Mater. Interfaces 9, 7675–7681 (2017).

Chen, C. et al. Highly flexible and efficient solar steam generation device. Adv. Mater. 29, 1701756 (2017).

Li, T. et al. Scalable and highly efficient mesoporous wood-based solar steam generation device: localized heat, rapid water transport. Adv. Funct. Mater. 28, 1707134 (2018).

Liu, H. et al. Narrow bandgap semiconductor decorated wood membrane for high-efficiency solar-assisted water purification. J. Mater. Chem. A 6, 18839–18846 (2018).

Kuang, Y. et al. A high-performance self-regenerating solar evaporator for continuous water desalination. Adv. Mater. 31, 1900498 (2019).

He, S. et al. Nature-inspired salt resistant bimodal porous solar evaporator for efficient and stable water desalination. Energy Environ. Sci. 12, 1558–1567 (2019).

Siria, A. et al. Giant osmotic energy conversion measured in a single transmembrane boron nitride nanotube. Nature 494, 455–458 (2013).

Kim, S. J., Ko, S. H., Kang, K. H. & Han, J. Direct seawater desalination by ion concentration polarization. Nat. Nanotechnol. 5, 297–301 (2010).

An, N., Fleming, A. M., White, H. S. & Burrows, C. J. Crown ether–electrolyte interactions permit nanopore detection of individual DNA abasic sites in single molecules. Proc. Natl Acad. Sci. USA 109, 11504–11509 (2012).

Fan, R., Huh, S., Yan, R., Arnold, J. & Yang, P. Gated proton transport in aligned mesoporous silica films. Nat. Mater. 7, 303–307 (2008).

Chen, G. et al. A highly conductive cationic wood membrane. Adv. Funct. Mater. 29, 1902772 (2019).

Fink, S. Transparent wood–a new approach in the functional study of wood structure. Holzforschung 46, 403–408 (1992).

Li, Y., Fu, Q., Yu, S., Yan, M. & Berglund, L. Optically transparent wood from a nanoporous cellulosic template: combining functional and structural performance. Biomacromolecules 17, 1358–1364 (2016).

Zhu, M. et al. Transparent and haze wood composites for highly efficient broadband light management in solar cells. Nano Energy 26, 332–339 (2016).

Li, Y. et al. Towards centimeter thick transparent wood through interface manipulation. J. Mater. Chem. A 6, 1094–1101 (2018).

Wu, J. et al. Impact of delignification on morphological, optical and mechanical properties of transparent wood. Compos. Part A Appl. Sci. Manuf. 117, 324–331 (2019).

Vasileva, E. et al. Light scattering by structurally anisotropic media: a benchmark with transparent wood. Adv. Opt. Mater. 6, 1800999 (2018).

Li, T. et al. Wood composite as an energy efficient building material: guided sunlight transmittance and effective thermal insulation. Adv. Energy Mater. 6, 1601122 (2016).

Yu, Z. et al. Transparent wood containing CsxWO3 nanoparticles for heat-shielding window applications. J. Mater. Chem. A 5, 6019–6024 (2017).

Vasileva, E. et al. Lasing from organic dye molecules embedded in transparent wood. Adv. Opt. Mater. 5, 1700057 (2017).

Li, Y. et al. Luminescent transparent wood. Adv. Opt. Mater. 5, 1600834 (2017).

Gan, W. et al. Luminescent and transparent wood composites fabricated by poly(methyl methacrylate) and γ-Fe2O3@YVO4:Eu3+ nanoparticle impregnation. ACS Sustain. Chem. Eng. 5, 3855–3862 (2017).

Gan, W. et al. Transparent magnetic wood composites based on immobilizing Fe3O4 nanoparticles into a delignified wood template. J. Mater. Sci. 52, 3321–3329 (2017).

Qiu, Z. et al. Transparent wood bearing a shielding effect to infrared heat and ultraviolet via incorporation of modified antimony-doped tin oxide nanoparticles. Compos. Sci. Technol. 172, 43–48 (2019).

Zhang, T. et al. Flexible transparent sliced veneer for alternating current electroluminescent devices. ACS Sustain. Chem. Eng. 7, 11464–11473 (2019).

Jia, C. et al. Clear wood toward high-performance building materials. ACS Nano 13, 9993–10001 (2019).

Kawasaki, T. & Kawai, S. Thermal insulation properties of wood-based sandwich panel for use as structural insulated walls and floors. J. Wood Sci. 52, 75–83 (2006).

Cetiner, I. & Shea, A. D. Wood waste as an alternative thermal insulation for buildings. Energy Build. 168, 374–384 (2018).

Chen, L., Song, N., Shi, L. & Ding, P. Anisotropic thermally conductive composite with wood-derived carbon scaffolds. Compos. Part A Appl. Sci. Manuf. 112, 18–24 (2018).

Kuang, Y. et al. Bioinspired solar-heated carbon absorbent for efficient cleanup of highly viscous crude oil. Adv. Funct. Mater. 29, 1900162 (2019).

Wan, J. et al. Highly anisotropic conductors. Adv. Mater. 29, 1703331 (2017).

Ma, L., Wang, Q. & Li, L. Delignified wood/capric acid-palmitic acid mixture stable-form phase change material for thermal storage. Sol. Energy Mater. Sol. Cell 194, 215–221 (2019).

Raman, A. P., Anoma, M. A., Zhu, L., Rephaeli, E. & Fan, S. Passive radiative cooling below ambient air temperature under direct sunlight. Nature 515, 540–544 (2014).

Tian, L. et al. A radiative cooling structural material. Science 364, 760–763 (2019).

Dong, A. et al. Zeolitic tissue through wood cell templating. Adv. Mater. 14, 926–929 (2002).

Ye, R. et al. Laser-induced graphene formation on wood. Adv. Mater. 29, 1702211 (2017).

Yang, H. et al. Self-luminous wood composite for both thermal and light energy storage. Energy Storage Mater. 18, 15–22 (2019).

Hai, J., Chen, F., Su, J., Xu, F. & Wang, B. Porous wood members-based amplified colorimetric sensor for Hg2+ detection through Hg2+-triggered methylene blue reduction reactions. Anal. Chem. 90, 4909–4915 (2018).

Chen, C. et al. Scalable and sustainable approach toward highly compressible, anisotropic, lamellar carbon sponge. Chem 4, 544–554 (2018).

Le, T.-S. D., Park, S., An, J., Lee, P. S. & Kim, Y.-J. Ultrafast laser pulses enable one-step graphene patterning on woods and leaves for green electronics. Adv. Funct. Mater. 29, 1902771 (2019).

Xi, J. et al. Wood-based straightway channel structure for high performance microwave absorption. Carbon 124, 492–498 (2017).

Yuan, Y. et al. Stiff, thermally stable and highly anisotropic wood-derived carbon composite monoliths for electromagnetic interference shielding. ACS Appl. Mater. Interfaces 9, 21371–21381 (2017).

Wang, Y. et al. A high-performance, low-tortuosity wood-carbon monolith reactor. Adv. Mater. 29, 1604257 (2017).

Tampieri, A. et al. From wood to bone: multi-step process to convert wood hierarchical structures into biomimetic hydroxyapatite scaffolds for bone tissue engineering. J. Mater. Chem. 19, 4973–4980 (2009).

Chen, C. et al. Catalyst-free in situ carbon nanotube growth in confined space via high temperature gradient. Research 2018, 1793784 (2018).

Li, Y. et al. In situ “Chainmail Catalyst” assembly in low-tortuosity, hierarchical carbon frameworks for efficient and stable hydrogen generation. Adv. Energy Mater. 8, 1801289 (2018).

Jakes, J. E. et al. Not just lumber—using wood in the sustainable future of materials, chemicals, and fuels. JOM 68, 2395–2404 (2016).

Burgert, I., Cabane, E., Zollfrank, C. & Berglund, L. Bio-inspired functional wood-based materials–hybrids and replicates. Int. Mater. Rev. 60, 431–450 (2015).

Stanzl-Tschegg, S. E. Wood as a bioinspiring material. Mater. Sci. Eng. C 31, 1174–1183 (2011).

Segmehl, J. S., Lauria, A., Keplinger, T., Berg, J. K. & Burgert, I. Tracking of short distance transport pathways in biological tissues by ultra-small nanoparticles. Front. Chem. 6, 28 (2018).

Merk, V., Berg, J. K., Krywka, C. & Burgert, I. Oriented crystallization of barium sulfate confined in hierarchical cellular structures. Cryst. Growth Des. 17, 677–684 (2017).

Gierlinger, N. & Schwanninger, M. Chemical imaging of poplar wood cell walls by confocal Raman microscopy. Plant. Physiol. 140, 1246–1254 (2006).

Keplinger, T. et al. Smart hierarchical bio-based materials by formation of stimuli-responsive hydrogels inside the microporous structure of wood. Adv. Mater. Interfaces 3, 1600233 (2016).

Segmehl, J. S., Studer, V., Keplinger, T. & Burgert, I. Characterization of wood derived hierarchical cellulose scaffolds for multifunctional applications. Materials 11, 517 (2018).

Synge, E. XXXVIII. A suggested method for extending microscopic resolution into the ultra-microscopic region. London Edinburgh Dublin Philos. Mag. J. Sci. 6, 356–362 (1928).

Pohl, D. W., Denk, W. & Lanz, M. Optical stethoscopy: image recording with resolution λ/20. Appl. Phys. Lett. 44, 651–653 (1984).

Deckert-Gaudig, T., Taguchi, A., Kawata, S. & Deckert, V. Tip-enhanced Raman spectroscopy–from early developments to recent advances. Chem. Soc. Rev. 46, 4077–4110 (2017).

Sharma, G., Deckert-Gaudig, T. & Deckert, V. Tip-enhanced Raman scattering—Targeting structure-specific surface characterization for biomedical samples. Adv. Drug Deliv. Rev. 89, 42–56 (2015).

Keplinger, T. et al. A zoom into the nanoscale texture of secondary cell walls. Plant Methods 10, 1 (2014).

Fahlén, J. & Salmén, L. Pore and matrix distribution in the fiber wall revealed by atomic force microscopy and image analysis. Biomacromolecules 6, 433–438 (2005).

Casdorff, K., Keplinger, T., Rüggeberg, M. & Burgert, I. A close-up view of the wood cell wall ultrastructure and its mechanics at different cutting angles by atomic force microscopy. Planta 247, 1123–1132 (2018).

Casdorff, K., Keplinger, T. & Burgert, I. Nano-mechanical characterization of the wood cell wall by AFM studies: comparison between AC-and QI™ mode. Plant Methods 13, 60 (2017).

Maire, E. X-ray tomography applied to the characterization of highly porous materials. Annu. Rev. Mater. Res. 42, 163–178 (2012).

Steppe, K. et al. Use of X-ray computed microtomography for non-invasive determination of wood anatomical characteristics. J. Struct. Biol. 148, 11–21 (2004).

Brodersen, C. R., Knipfer, T. & McElrone, A. J. In vivo visualization of the final stages of xylem vessel refilling in grapevine (Vitis vinifera) stems. New Phytol. 217, 117–126 (2018).

Zauner, M., Stampanoni, M. & Niemz, P. Failure and failure mechanisms of wood during longitudinal compression monitored by synchrotron micro-computed tomography. Holzforschung 70, 179–185 (2016).

Jakob, H., Fengel, D., Tschegg, S. & Fratzl, P. The elementary cellulose fibril in Picea abies: comparison of transmission electron microscopy, small-angle X-ray scattering, and wide-angle X-ray scattering results. Macromolecules 28, 8782–8787 (1995).

Färber, J., Lichtenegger, H., Reiterer, A., Stanzl-Tschegg, S. & Fratzl, P. Cellulose microfibril angles in a spruce branch and mechanical implications. J. Mater. Sci. 36, 5087–5092 (2001).

Entwistle, K. M., Eichhorn, S. J. & Navaranjan, N. The derivation of the cellulose microfibril angle by small-angle X-ray scattering from structurally characterized softwood cell-wall populations. J. Appl. Crystallogr. 38, 505–511 (2005).

Penttilä, P. A., Rautkari, L., Österberg, M. & Schweins, R. Small-angle scattering model for efficient characterization of wood nanostructure and moisture behaviour. J. Appl. Crystallogr. 52, 369–377 (2019).

Mansfield, S. D., Kim, H., Lu, F. & Ralph, J. Whole plant cell wall characterization using solution-state 2D NMR. Nat. Protoc. 7, 1579–1589 (2012).

Bergenstråhle, M., Berglund, L. A. & Mazeau, K. Thermal response in crystalline Iβ cellulose: a molecular dynamics study. J. Phys. Chem. B 111, 9138–9145 (2007).

Ciesielski, P. N. et al. Nanomechanics of cellulose deformation reveal molecular defects that facilitate natural deconstruction. Proc. Natl Acad. Sci. USA 116, 9825–9830 (2019).

Chen, P., Ogawa, Y., Nishiyama, Y., Ismail, A. E. & Mazeau, K. Iα to Iβ mechano-conversion and amorphization in native cellulose simulated by crystal bending. Cellulose 25, 4345–4355 (2018).

López, C. A. et al. MARTINI coarse-grained model for crystalline cellulose microfibers. J. Phys. Chem. B 119, 465–473 (2015).

Nairn, J. A. Numerical simulations of transverse compression and densification in wood. Wood Fiber Sci. 38, 576–591 (2007).

O’Loinsigh, C., Oudjene, M., Shotton, E., Pizzi, A. & Fanning, P. Mechanical behaviour and 3D stress analysis of multi-layered wooden beams made with welded-through wood dowels. Compos. Struct. 94, 313–321 (2012).

Belhaj, K., Chaparro-Garcia, A., Kamoun, S., Patron, N. J. & Nekrasov, V. Editing plant genomes with CRISPR/Cas9. Curr. Opin. Biotechnol. 32, 76–84 (2015).

Fu, C. et al. Genetic manipulation of lignin reduces recalcitrance and improves ethanol production from switchgrass. Proc. Natl Acad. Sci. USA 108, 3803–3808 (2011).

Yu, Z.-L. et al. Bioinspired polymeric woods. Sci. Adv. 4, eaat7223 (2018).

Zorzetto, L. & Ruffoni, D. Wood-inspired 3D-printed helical composites with tunable and enhanced mechanical performance. Adv. Funct. Mater. 29, 1805888 (2019).

Kobayashi, K., Akada, M., Torigoe, T., Imazu, S. & Sugiyama, J. Automated recognition of wood used in traditional Japanese sculptures by texture analysis of their low-resolution computed tomography data. J. Wood Sci. 61, 630–640 (2015).

Kobayashi, K., Hwang, S.-W., Okochi, T., Lee, W.-H. & Sugiyama, J. Non-destructive method for wood identification using conventional X-ray computed tomography data. J. Cult. Herit. 38, 88–93 (2019).

Barthelat, F., Yin, Z. & Buehler, M. J. Structure and mechanics of interfaces in biological materials. Nat. Rev. Mater. 1, 16007 (2016).

Acknowledgements

The authors thank A. H. Brozena for valuable comments on the manuscript and J. Dai for the helpful discussion on Fig. 1.

Author information

Authors and Affiliations

Contributions

L.H. and C.C. researched data for the manuscript. All authors made substantial contributions to the discussion of the content. C.C., L.H., Y.K., S.Z., I.B., T.K., T.L. and S.J.E. contributed to writing the manuscript. All authors reviewed and/or edited the manuscript before submission.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, C., Kuang, Y., Zhu, S. et al. Structure–property–function relationships of natural and engineered wood. Nat Rev Mater 5, 642–666 (2020). https://doi.org/10.1038/s41578-020-0195-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41578-020-0195-z

This article is cited by

-

Determination of nuclear magnetic resonance surface relaxivity for the macropore system from wood cell lumen

Journal of Wood Science (2024)

-

Machine intelligence-accelerated discovery of all-natural plastic substitutes

Nature Nanotechnology (2024)

-

Bioinspired strategies for biomimetic actuators from ultrafast to ultraslow

Nano Research (2024)

-

Insights into Nano- and Micro-Structured Scaffolds for Advanced Electrochemical Energy Storage

Nano-Micro Letters (2024)

-

Green supercapacitor patterned by synthesizing MnO/laser-induced-graphene hetero-nanostructures on wood via femtosecond laser pulses

Biochar (2024)