Abstract

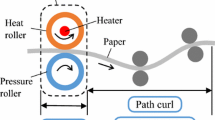

The moisture transport at the fuser nip of printers is postulated to be the main reason for paper curls. However, the fundamental mechanisms of paper curling remain unclear. Observing the moisture transport inside a sheet of paper through experiments is difficult because moisture transport rapidly occurs in a micro-scale thickness. Therefore, developing a theoretical model is crucial to understand the mechanisms of paper curling and to control the curls. In this study, we proposed a multiphysics model that includes the moisture and heat transport and mechanical deformation. The elasticity, plasticity, viscosity, and expansion caused by moisture were considered in the mechanical model to describe the complex material characteristics of paper. The curvature of curls was calculated using an effective two-spring model. The mechanisms of curling in printers and the direction of curls were understood through finite element simulations. The proposed model can qualitatively predict the paper curls observed in experiments. The temperature- and moisture-dependent material properties of paper will be studied in the future to improve the proposed model.

Similar content being viewed by others

References

S. Lee and G. H. Yoon, Moisture transport in paper passing through the fuser nip of a laser printer, Cellulose, 24 (8) (2017) 3489–3501.

A. H. Bedane, H. Xiao and M. Eić, Water vapor adsorption equilibria and mass transport in unmodified and modified cellulose fiber-based materials, Adsorption, 20 (7) (2014) 863–874.

A. Bandyopadhyay, B. Ramarao and S. Ramaswamy, Transient moisture diffusion through paperboard materials, Colloids Surf A, 206 (1) (2002) 455–467.

A. Bandyopadhyay, H. Radhakrishnan, B. V. Ramarao and S. G. Chatterjee, Moisture sorption response of paper subjected to ramp humid changes: Modeling and experiments, Industrial & Engineering Chemistry Research, 39 (1) (2000) 219–226.

A. E. Saez, C. J. Otero and I. Rusinek, The effective homogeneous behavior of heterogeneous porous media, Transport in Porous Media, 4 (3) (1989) 213–238.

M. Lindner, Factors affecting the hygroexpansion of paper, Journal of Materials Science, 53 (1) (2018) 1–26.

M. Alava and K. Niskanen, The physics of paper, Reports on Progress in Physics, 69 (3) (2006) 669–723.

P. Lipponen, T. Leppänen, J. Kouko and J. Hämäläinen, Elasto-plastic approach for paper cockling phenomenon: On the importance of moisture gradient, International Journal of Solids and Structures, 45 (11) (2008) 3596–3609.

M. L. Dano and J. P. Bourque, Deformation behavior of paper and board subjected to moisture diffusion, International Journal of Solids and Structures, 46 (6) (2009) 1305–1316.

T. Mohammadnejad and A. R. Khoei, An extended finite element method for hydraulic fracture propagation in deformable porous media with the cohesive crack model, Finite Elements in Analysis and Design, 73 (2013) 77–95.

D. Soares and L. C. Wrobel, Solution of hyperbolic bioheat conduction models based on adaptive time integrators, Finite Elements in Analysis and Design, 149 (2018) 1–14.

P. A. Larsson and L. Wågberg, Diffusion-induced dimensional changes in papers and fibrillar films: Influence of hydrophobic-ity and fibre-wall cross-linking, Cellulose, 17 (5) (2010) 891–901.

P. A. M. Zapata, M. Fransen, J. ten Thije Boonkkamp and L. Saes, Coupled heat and moisture transport in paper with application to a warm print surface, Applied Mathematical Modeling, 37 (12) (2013) 7273–7286.

J. Fan and X. Wen, Modeling heat and moisture transfer through fibrous insulation with phrase change and mobile condensates, International Journal of Heat and Mass Transfer, 45 (19) (2002) 4045–4055.

A. H. Bedane, M. Eić, M. Farmahini-Farahani and H. Xiao, Theoretical modeling of water vapor transport in cellulose-based materials, Cellulose, 23 (3) (2016) 1537–1552.

H. Gupta and S. G. Chatterjee, Parallel diffusion of moisture in paper. Part 1: Steady-state conditions, Industrial and Engineering Chemistry Research, 42 (25) (2003) 6582–6592.

H. Gupta and S. G. Chatterjee, Parallel diffusion of moisture in paper. Part 2: Transient conditions, Industrial and Engineering Chemistry Research, 42 (25) (2003) 6582–6592.

P. Harrison, M. F. Alvares and D. Anderson, Towards comprehensive characterization and modeling of the forming and wrinkling mechanics of engineering fabrics, International Journal of Solids and Structures, 154 (2018) 2–18.

E. Bosco, R. H. J. Peerlings, B. A. G. Lomans, C. G. van der Sman and M. G. D. Geers, On the role of moisture in triggering out-of-plane displacement in paper: From the network level to the macroscopic scale, International Journal of solids and Structures, 154 (2018) 66–77.

M. E. Parker, J. E. Bronlund and A. J. Mawson, Moisture sorption isotherms for paper and paperboard in food chain conditions, Packaging Technology and Science: An International Journal, 19 (4) (2006) 193–209.

E. J. Quirijins, A. J. Van Boxtel, W. K. van Loon and G. Van Straten, Sorption isotherms, GAB parameters and isosteric heat of sorption, Journal of the Science of Food and Agriculture, 85 (11) (2005) 1805–1814.

W. Ramberg and W. R. Osgood, Technical Note No. 902 Description of Stress-strain Curves by Three Parameters, National Advisory Committee for Aeronautics, Washington DC (1943).

H. Huang, C. Ye and V. Sun, Moisture transport in fibrous clothing assemblies, Journal of Engineering Mathematics, 61 (1) (2008) 35–54.

Acknowledgments

This work was supported by the research grant of HP, the National Research Foundation of Korea grant of the Korean government Ministry of Science and ICT (no. 2018R1A5A 7025522), and the research program of Dongguk University, 2020.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Seungjae Min

Gil Ho Yoon received his B.S., M.S., and Ph.D. degrees in Mechanical and Aerospace Engineering from Seoul National University in 1998, 2000, and 2004, respectively. He currently serves as a Professor at the School of Mechanical Engineering in Hanyang University, Seoul, Republic of Korea.

Taehan Kim leads the mechanical simulation team of HP Printing Korea (formerly Printing Solution Business at Samsung Electronics). He has worked at the automotive and printing industry for more than 20 years. His current research interests include modeling and analyzing the multidisciplinary area of printing system, including multiphysics simulation. He received his Ph.D. in aeronautics and astronautics with specialization in composite structures from Stanford University.

Byoungho Yoo received his B.S. and M.S. degrees in naval ocean engineering from Seoul National University in 1996. He has worked on mechanical computer-aided engineering, including vibration and paper path dynamics, at Samsung Electronics Printing Division and at HP since 2017.

Woon Kyung Kim is a Senior Research Engineer of the mechanical simulation team at HP Printing Korea, Pangyo, Korea. He received his Ph.D. degree in mechanical engineering from Virginia Tech, Virginia, USA, with specialization on smart material systems and structures. His research interests include multifunctional composite structure analysis, dynamic simulation, and optimization design of laser printing systems.

Junseong Woo is a Senior Research Engineer of the CAE team at HP Printing Korea, Pangyo, Korea. He received his M.S. degree in mechanical engineering from Ajou University, Korea, with specialization on structural fatigue of multi-body systems. His research interests include paper behavior and dynamic simulation of printer units for improving image defects.

Seungjun Lee is an Assistant Professor of Mechanical, Robotics, and Energy Engineering at Dongguk University, Seoul, Korea. He received his B.S. degree in naval architecture and ocean engineering from Seoul National University and his M.S. and Ph.D. degrees in mechanical engineering from the University of Michigan, Ann Arbor, Michigan, USA. His research interest includes multi-scale simulations and mechanical behavior at nano/microscales.

Rights and permissions

About this article

Cite this article

Yoon, G.H., Yoo, B., Kim, W.K. et al. Multiphysics simulation of paper curl due to moisture transport. J Mech Sci Technol 34, 2075–2083 (2020). https://doi.org/10.1007/s12206-020-0429-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-020-0429-4