Abstract

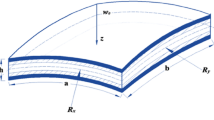

We conducted an experimental investigation on the flexural behavior of closed-cell aluminum foam beam under shear stress effect. Three-point bending and flexural vibration tests were carried out and the shear stress effect was generated by changing the specimen’s length. From the bending test, the measured deflection was used to quantify the flexural modulus. From the vibration test, the measured natural frequencies of flexural vibration mode were used to calculate the flexural modulus. The results show that the flexural moduli obtained from both tests agree well. Then, the flexural modulus value was compared with the theoretical value estimated by Timoshenko’s beam theory. As a result, the experimental value was found to be much smaller than the theoretical value when shear stress effect is dominant. Does this mean Timoshenko’s theory cannot describe the flexural behavior of aluminum foam beam? How to fit Timoshenko’s theory with the experimental data is discussed. Moreover, the reason why the flexural modulus was remarkably degraded under shear effect is elaborated.

Similar content being viewed by others

Abbreviations

- P :

-

Applied load

- L s :

-

Span length between two supports

- I :

-

Second moment of inertia

- δ :

-

Beam deflection

- f :

-

Natural frequency

- ρ :

-

Density

- ρ * :

-

Normalized density by bulk aluminum

- A :

-

Cross sectional area

- L :

-

Length of flexural vibration test specimen

- h :

-

Thickness of specimen

- λ i :

-

Eigen value

- E f :

-

Flexural modulus

- E * :

-

Flexural modulus with shear effect

- E :

-

Young modulus

- G :

-

Shear modulus

- s :

-

Timoshenko’s shear factor

- v :

-

Poisson’s ratio

References

M. F. Ashby, A. Evans, N. A. Fleck, L. J. Gibson, J. W. Hut-chinson and H. N. G. Wadley, Metal Foams: A Design Guide, Butterworth-Heinemann, Oxford (2000).

T. Dirgantara, A. Jusuf, E. O. Kurniati, L. Gunawan and I. S. Putra, Crashworthiness analysis of foam-filled square column considering strain rate effect of the foam, Thin-Walled Structures, 129 (2018) 365–380.

H. Farahat and S. Y. A. Brooghani, Effect of heat treatment on the low velocity impact response of A356/SiCp composite foam, Journal of Mechanical Science and Technology, 31 (7) (2017) 3347–3354.

T. Miyoshi, M. Itoh, S. Akiyama and A. Kitahara, ALPORAS aluminum foam: Production process, properties, and applications, Advanced Engineering Materials, 2 (4) (2000) 179–183.

A. G. Evans, J. W. Hutchinson and M. F. Ashby, Multifunction-ality of cellular metal systems, Progress in Materials Science, 43 (3) (1998) 171–221.

J. Banhart, Manufacture, characterization and application of cellular metals and metal foams, Progress in Materials Science, 46 (6) (2001) 559–632.

T. Miyoshi, T. Hamada and H. Kanahashi, Development of porous aluminum alloy with parts having excellent crashwor-thiness, Kobe Steeling Engineering Reports, 57 (2) (2007) 95–100.

F. Triawan, K. Kishimoto, T. Adachi, K. Inaba, T. Nakamura, Z. Lin and T. Hashimura, Elastic bending behavior of aluminum alloy foam, Procedia Engineering, 10 (2011) 2994–2999.

F. Triawan, K. Kishimoto, T. Adachi, K. Inaba, T. Nakamura and T. Hashimura, The elastic behavior of aluminum alloy foam under uniaxial loading and bending conditions, Acta Ma-terialia, 60 (6-7) (2012) 3084–3093.

F. Triawan, B. A. Budiman, F. B. Juangsa, L. A. Prananto and M. Aziz, Finite element analysis on the unloading elastic modulus of aluminum foams by unit-cell model, IOP Conference Series: Materials Science and Engineering, 288 (1) (2018) 012069.

D. Renjun, Z. Xinna, H. Qingxian, J. Yan and H. Yuebo, Simulation analysis of effect of porosity on compression behavior and energy absorption properties of aluminum foam sandwich panels, Materials Transactions, 57 (1) (2016) 33–36.

C. A. Steeves and N. A. Fleck, Collapse mechanisms of sandwich beams with composite faces and a foam core. Part I: Analytical models and minimum weight design, International Journal of Mechanical Sciences, 46 (4) (2004) 561–583.

C. Tekoglu,. J. Gibson, T. Pardoen and P. R. Onck, Size effect in foams: Experiments and modeling, Progress in Materials Science, 56 (2) (2011) 109–138.

Y. Sun, B. Amirrasouli, S. B. Razavi, Q. M. Li, T. Lowe and P. J. Withers, The variation in elastic modulus throughout the compression of foam materials, Acta Materialia, 110 (2016) 161–174.

A. E. Simone and L. J. Gibson, Aluminum foams produced by liquid-state processes, Acta Materialia, 46 (1998) 3109–3123.

E. Andrews, W. Sanders and L. J. Gibson, Compressive and tensile behavior of aluminum foams, Materials Science and Engineering: A, 270 (2) (1999) 113–124.

H. Yoshimura, Simulation for plastic deformation of ultralight porous metals, Materia Japan, 47 (4) (2008) 186–190 (in Japanese).

H. Yoshihara, Y. Kubojima, K. Nagaoka and M. Ohta, Measurement of the shear modulus of wood by static bending tests, Journal of Wood Science, 44 (1) (1998) 15–20.

Acknowledgments

Authors would like to thank Dr. Toru Hashimura of Kobe Steel, Ltd. for the valuable discussion in analyzing the experimental data.

Author information

Authors and Affiliations

Corresponding author

Additional information

Farid Triawan is currently the Head of Mechanical Engineering Department, Faculty of Engineering and Technology, Sampoerna University, Indonesia. He received his Bachelor’s from Bandung Institute of Technology, Indonesia, then Master’s and Doctoral from Tokyo Institute of Technology, Japan. His fields of interest are solid mechanics, mechanics of porous materials, damage mechanics, and cavitation erosion phenomenon.

Rights and permissions

About this article

Cite this article

Triawan, F., Nakagawa, R., Inaba, K. et al. Experimental investigation of shear stress effect on the flexural behavior of aluminum foam beam. J Mech Sci Technol 34, 1831–1836 (2020). https://doi.org/10.1007/s12206-020-0403-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-020-0403-1